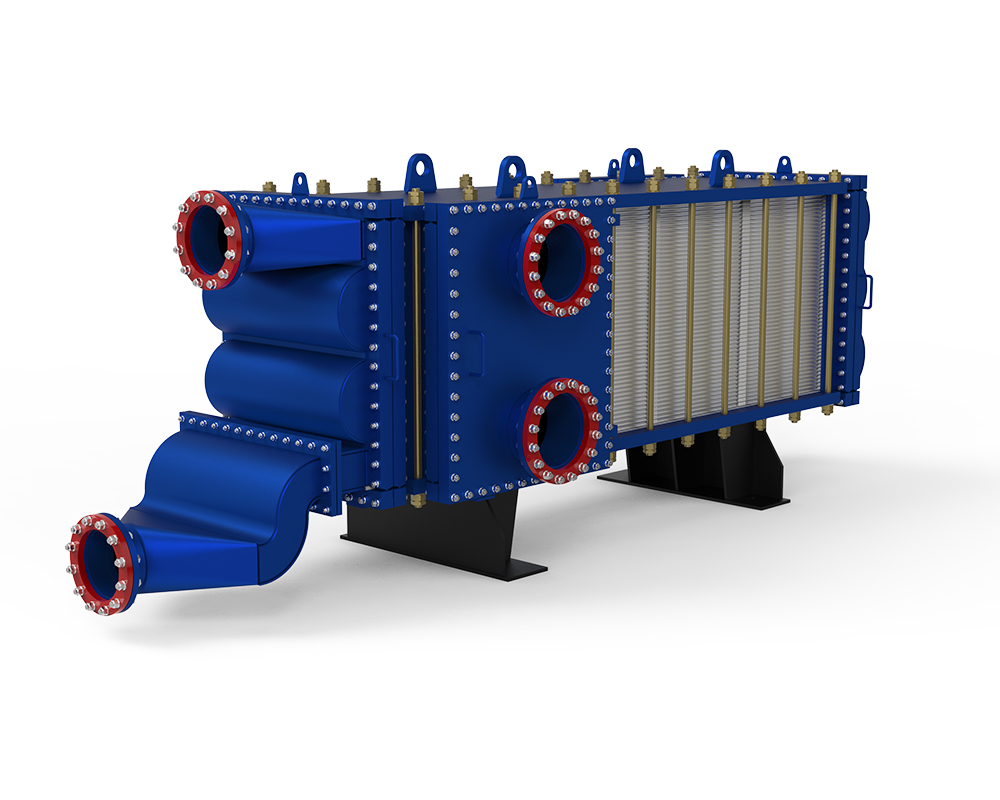

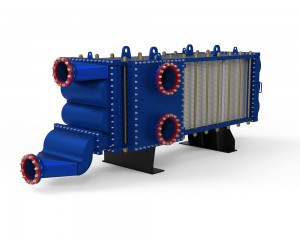

I-Wide Gap Welded Plate Heat Exchanger ye-Alumina yokuhluza

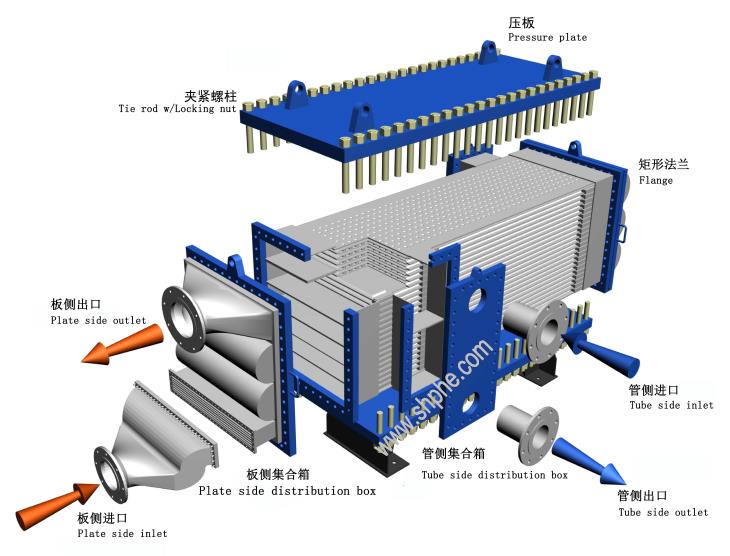

Isebenza kanjani?

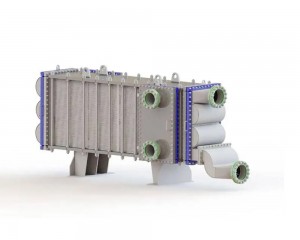

Isishintshi sokushisa sepuleti singasetshenziselwa ikakhulukazi ukwelashwa okushisayo okufana nokushisa kanye nokupholisa phansi kwe-viscous medium noma okuphakathi kuqukethe izinhlayiya ezimahhadla nokumiswa kwefayibha kushukela, ukwenza iphepha, i-metallurgy, i-ethanol nezimboni zamakhemikhali.

Idizayini ekhethekile yepuleti lokushintshanisa ukushisa iqinisekisa ukusebenza kahle kokudlulisa ukushisa nokulahlekelwa kwengcindezi kunezinye izinhlobo zemishini yokushintshanisa ukushisa esesimweni esifanayo. Ukugeleza okushelelayo koketshezi esiteshini esinegebe elibanzi nakho kuyaqinisekiswa. Iyaqaphela inhloso yokungabi "indawo efile" futhi akukho ukubekwa noma ukuvinjelwa kwezinhlayiya ezimahhadla noma ukumiswa.

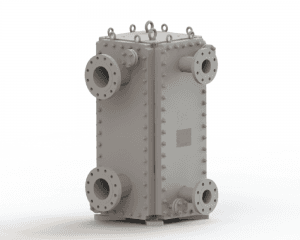

Ishaneli ohlangothini olulodwa kwakheka phakathi kwepuleti eliyisicaba kanye nepuleti eliyisicaba elishiselwe kanye ne-stud. Isiteshi ngakolunye uhlangothi sakhiwe phakathi kwamapuleti ayisicaba anegebe elibanzi, futhi alikho iphuzu lokuxhumana. Zombili iziteshi zifanele i-viscous medium ephezulu noma ephakathi equkethe izinhlayiya ezimahhadla nefiber.

Isicelo

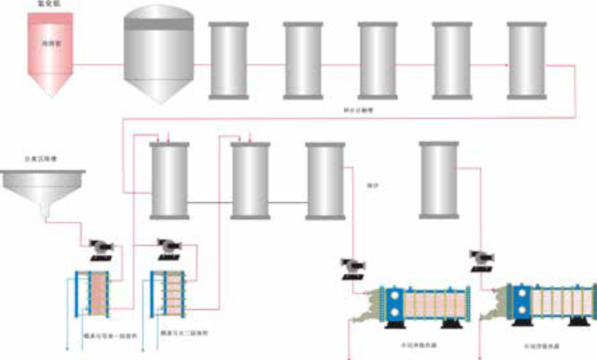

I-alumina, ikakhulukazi i-sand alumina, iyimpahla eluhlaza ye-alumina electrolysis. Inqubo yokukhiqiza ye-alumina ingahlukaniswa njengenhlanganisela ye-Bayer-sintering. Ukusetshenziswa kwesishintshi sokushisa kwamapuleti embonini ye-alumina kunciphisa ngempumelelo ukuguguleka nokuvinjelwa, okubuye kwandise ukusebenza kahle kwesishintshi sokushisa kanye nokusebenza kahle kokukhiqiza.

Izishintshi zokushisa ze-Plate zisetshenziswa njengokupholisa kwe-PGL, ukupholisa i-agglomeration kanye nokupholisa kwe-interstage.

Isishintshi sokushisa sisetshenziswa engxenyeni yokusebenzela yokwehla kwezinga lokushisa eliphakathi nendawo ekuwohlokeni nasekuhleleni umsebenzi wohlelo ohlelweni lokukhiqiza i-alumina, efakwa phezulu noma phansi ethangini lokubola futhi isetshenziselwe ukwehlisa izinga lokushisa le-aluminium hydroxide slurry kwinqubo yokubola.