Carbon Emissions Carbon Emissions

|

Achieve a total reduction of 50% in carbon emissions across all stages, including Scope 1, 2, and 3 emissions. |

Energy Efficiency Energy Efficiency

|

Improve energy efficiency by 5% (measured in MWh per unit of production). |

Water Usage Water Usage

|

Achieve over 95% recycling and reuse of water. |

Waste Waste

|

Reutilize 80% of waste materials. |

Chemicals Chemicals

|

Ensure that no hazardous chemicals are used by regularly updating safety protocols and documentation. |

Safety Safety

|

Achieve zero workplace accidents and zero worker injuries. |

Employee Training Employee Training

|

Ensure 100% employee participation in on-the-job training. |

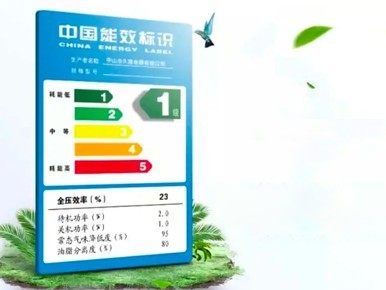

At the same heat exchange capacity, SHPHE’s removable plate heat exchangers are designed to use the least amount of energy. From research and development to design, simulation, and precision manufacturing, we ensure optimal product performance. SHPHE offers over 10 series of top-tier energy-efficient products, including models with over 350 corner holes at the highest efficiency level. Compared to 3rd-level energy-efficient plate heat exchangers, our E45 model, processing 2000m³/h, can save approximately 22 tons of standard coal annually and reduce CO2 emissions by around 60 tons.

Every researcher draws inspiration from nature’s energy transfer, applying biomimicry principles to meet customer requirements while maximizing safety and energy efficiency. Our latest wide-channel welded plate heat exchangers improve heat transfer efficiency by 15% compared to traditional models. By studying natural energy transfer phenomena—such as how fish reduce drag while swimming or how ripples transfer energy in water—we integrate these principles into product design. This combination of biomimicry and advanced engineering pushes the performance of our heat exchangers to new heights, fully harnessing the wonders of nature in their design.

High-quality solution system integrator in the field of heat exchanger

Shanghai Heat Transfer Equipment Co., Ltd. provides you with the design, manufacturing, installation and service of plate heat exchangers and their overall solutions, so that you can be worry-free about products and after-sales.