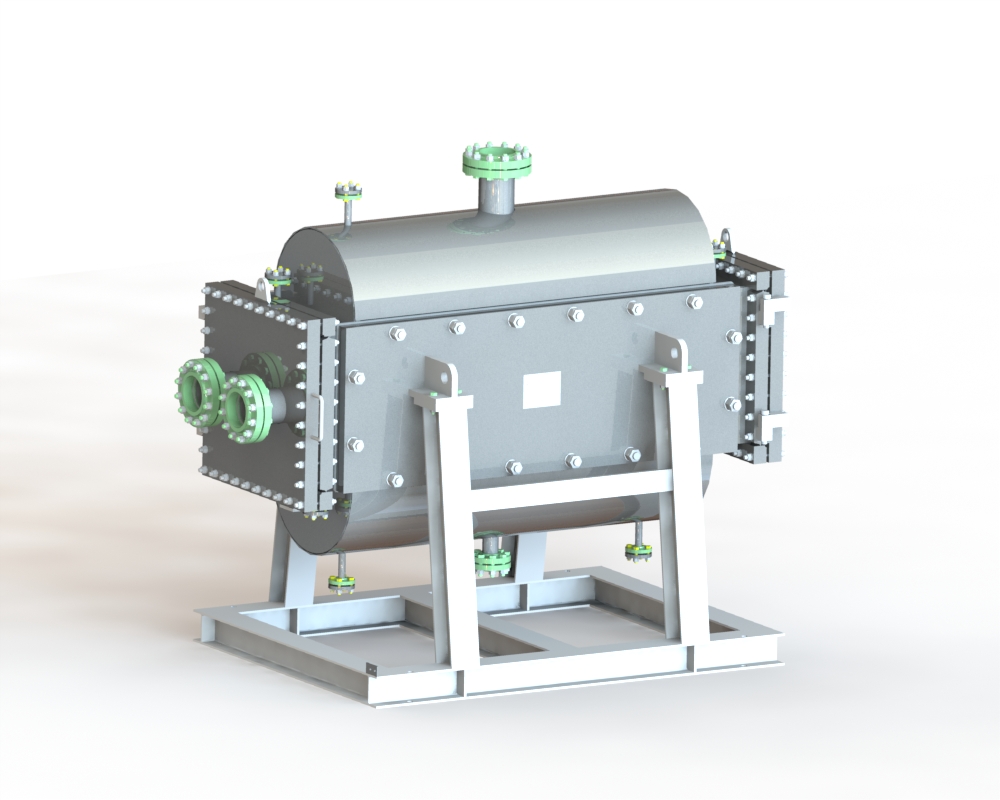

Special Price for Counterflow Heat Exchanger - Horizontal Precipitation Slurry Cooler in Alumina Refinery – Shphe

Special Price for Counterflow Heat Exchanger - Horizontal Precipitation Slurry Cooler in Alumina Refinery – Shphe Detail:

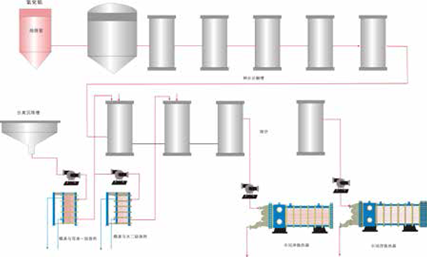

Production process of alumina

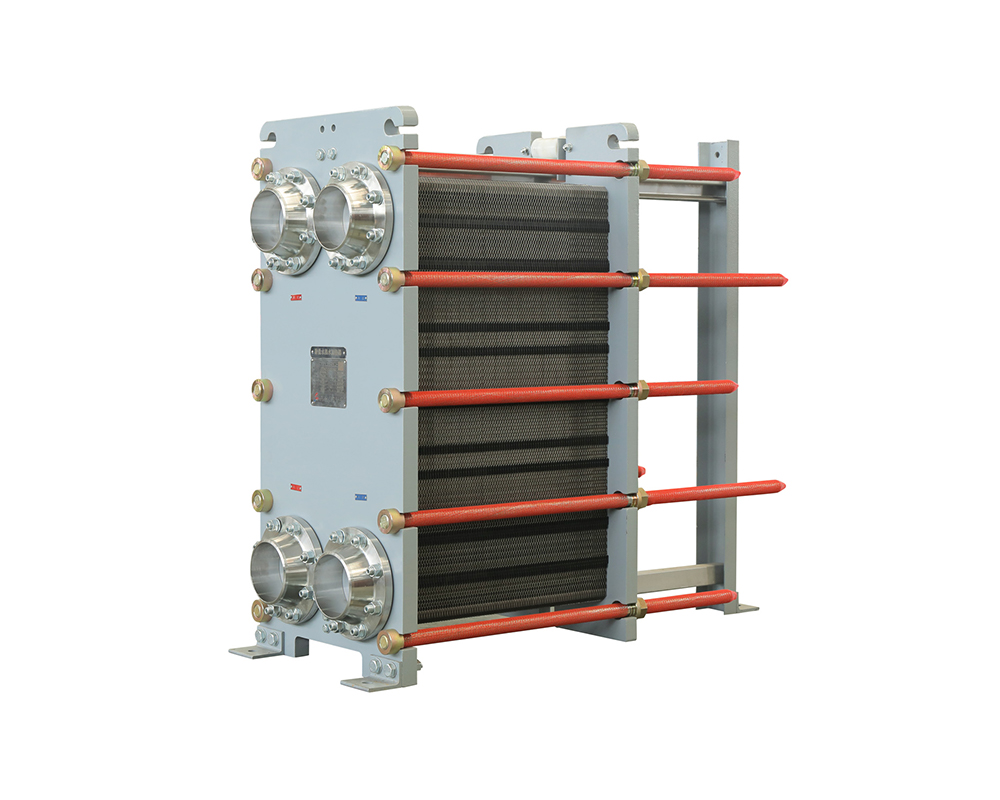

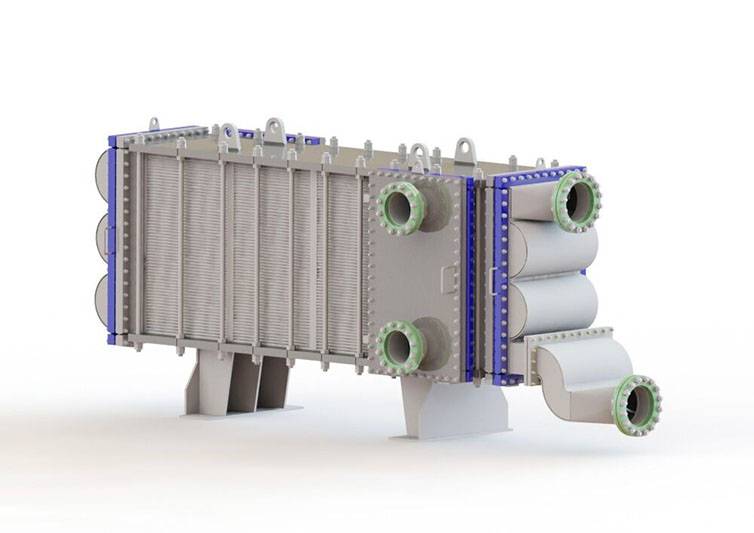

Alumina, mainly sand alumina, is the raw material for alumina electrolysis. The production process of alumina can be classified as Bayer-sintering combination. Wide Gap Welded Plate Heat Exchanger is applied in Precipitation area in the production process of alumina, which is installed on the top or bottom of decomposition tank and used for reducing the temperature of aluminum hydroxide slurry in the decomposition process.

Why Wide Gap Welded Plate Heat Exchanger?

The application of Wide Gap Welded Plate Heat Exchanger in alumina refinery successfully reduces erosion and blockage, which in turn increased heat exchanger efficiency as well as production efficiency. Its main applicable characteristics are as follows:

1. Horizontal structure, High flow rate brings the slurry which contains solid particles to flow on the surface of plate and effectively refraining the sedimentation and scar.

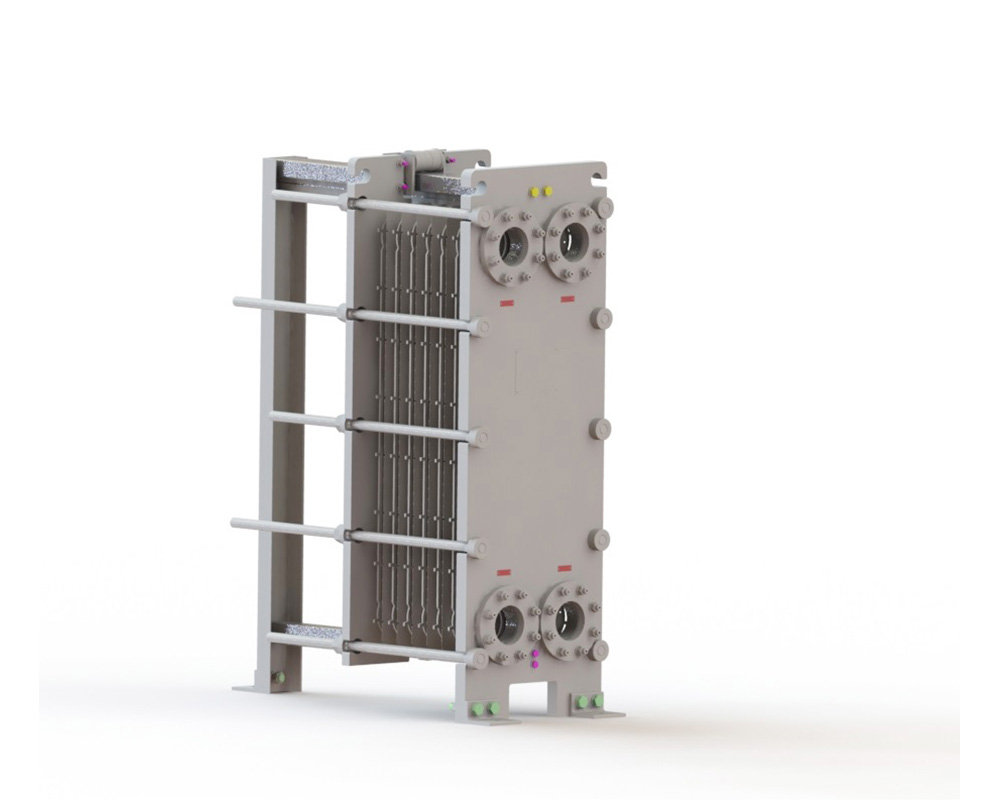

2. The wide channel side has no touching point so that the liquid can flow freely and completely in flow path formed by the plates. Almost all the plate surfaces are involved in the heat exchange, which realizes the flow of no ”Dead spots” in the flow path.

3. There is distributor in the slurry inlet, which makes the slurry enter the path uniformly and reduces erosion.

4. Plate material: Duplex steel and 316L.

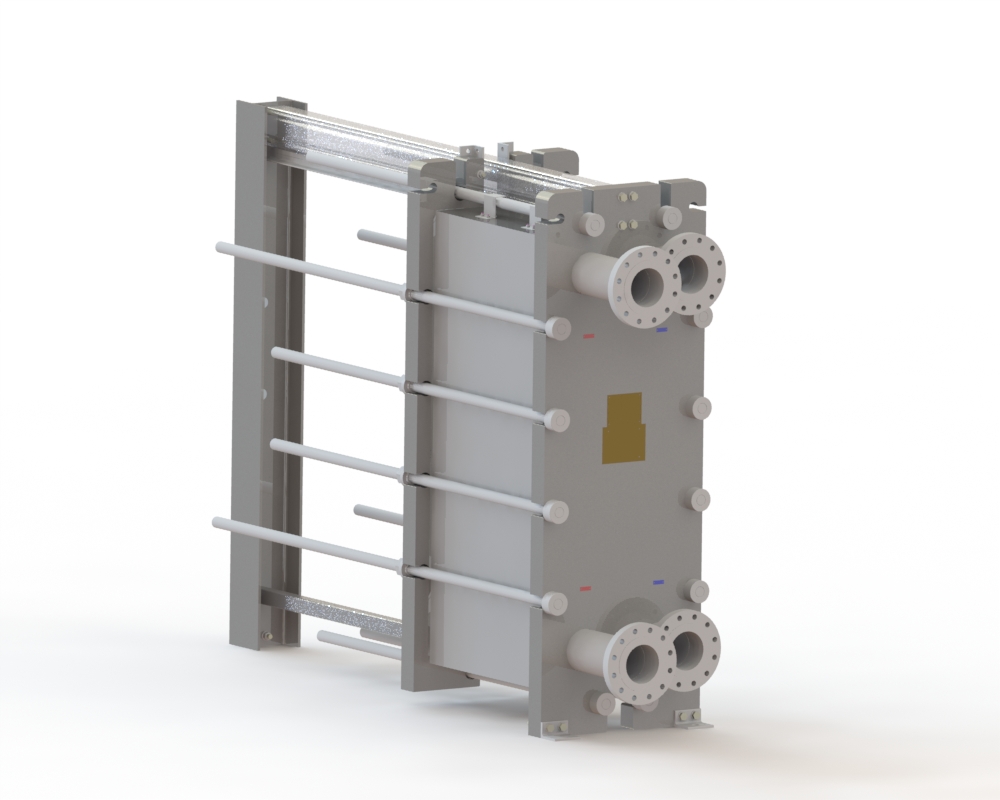

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Special Price for Counterflow Heat Exchanger - Horizontal Precipitation Slurry Cooler in Alumina Refinery – Shphe , The product will supply to all over the world, such as: Barcelona , Chicago , Bulgaria , Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.