Professional China Compact Heat Exchanger - Horizontal Precipitation Slurry Cooler in Alumina Refinery – Shphe

Professional China Compact Heat Exchanger - Horizontal Precipitation Slurry Cooler in Alumina Refinery – Shphe Detail:

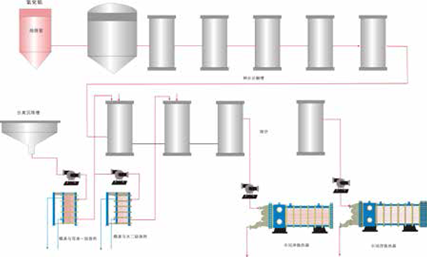

Production process of alumina

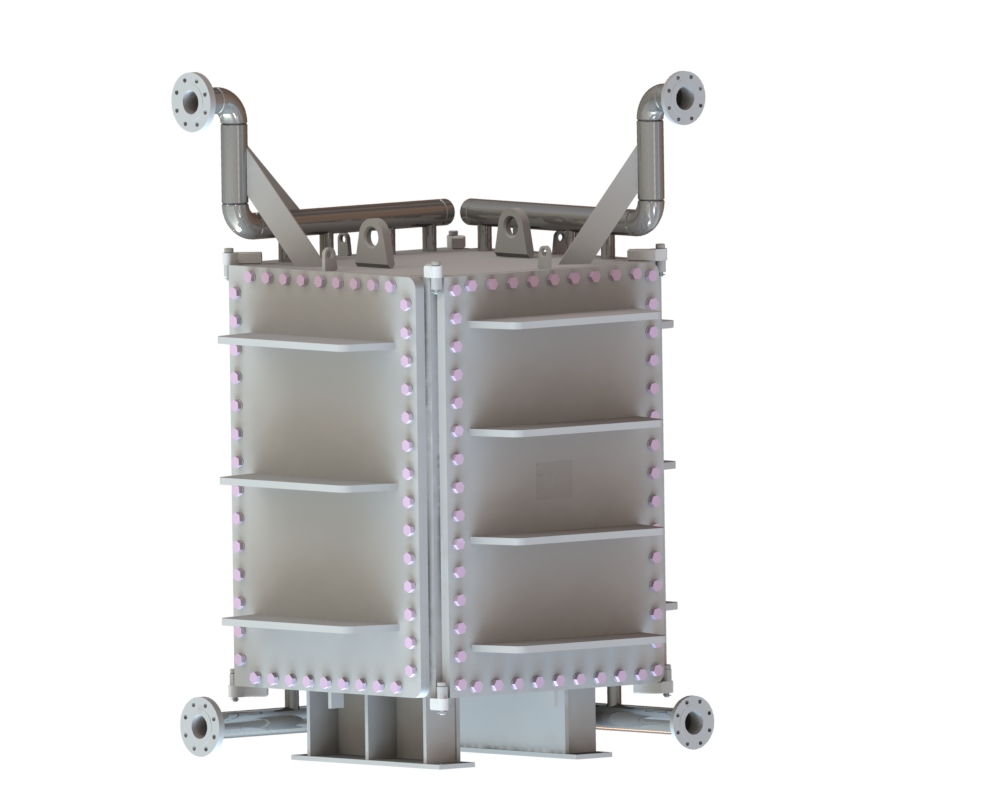

Alumina, mainly sand alumina, is the raw material for alumina electrolysis. The production process of alumina can be classified as Bayer-sintering combination. Wide Gap Welded Plate Heat Exchanger is applied in Precipitation area in the production process of alumina, which is installed on the top or bottom of decomposition tank and used for reducing the temperature of aluminum hydroxide slurry in the decomposition process.

Why Wide Gap Welded Plate Heat Exchanger?

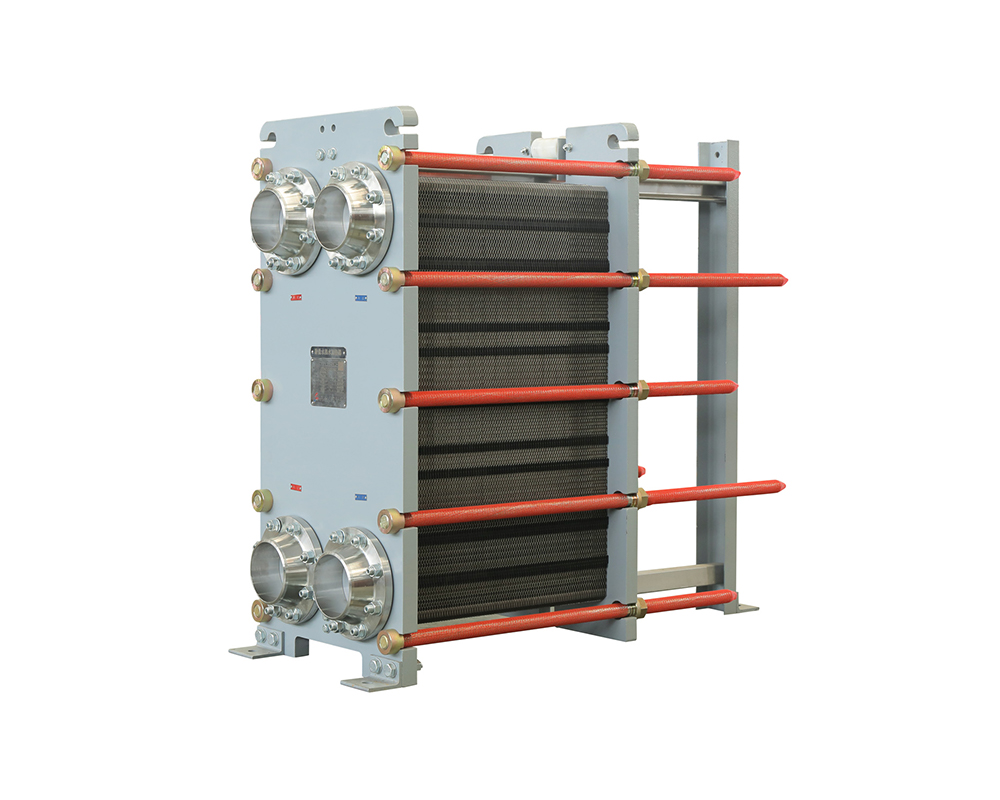

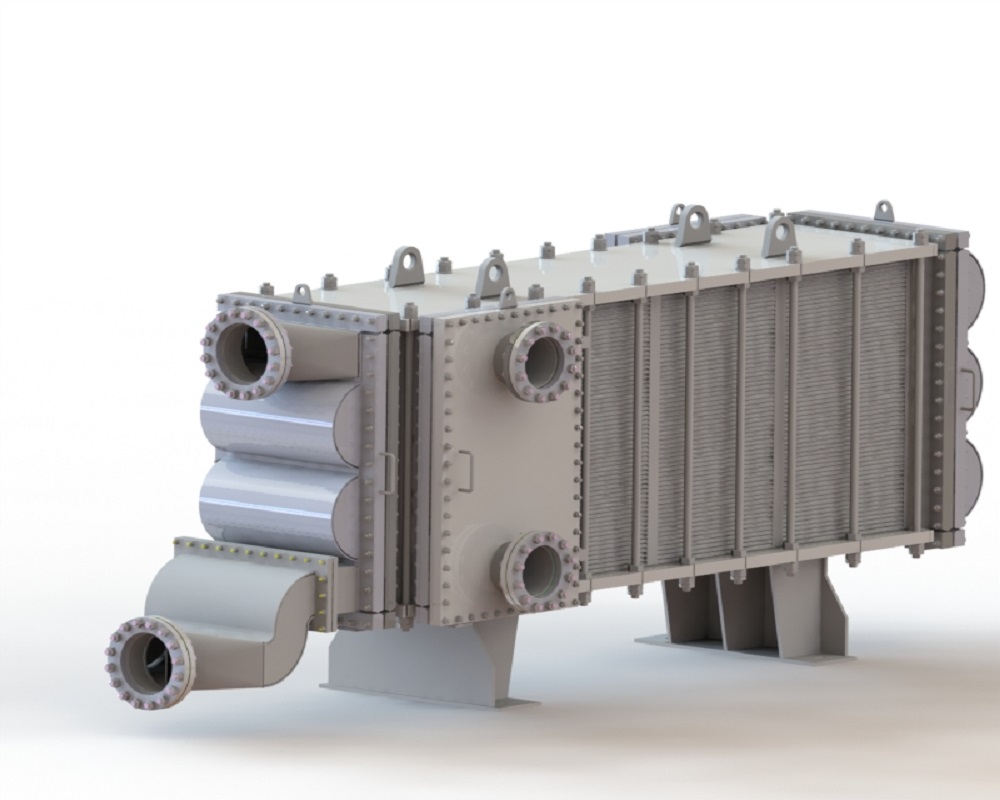

The application of Wide Gap Welded Plate Heat Exchanger in alumina refinery successfully reduces erosion and blockage, which in turn increased heat exchanger efficiency as well as production efficiency. Its main applicable characteristics are as follows:

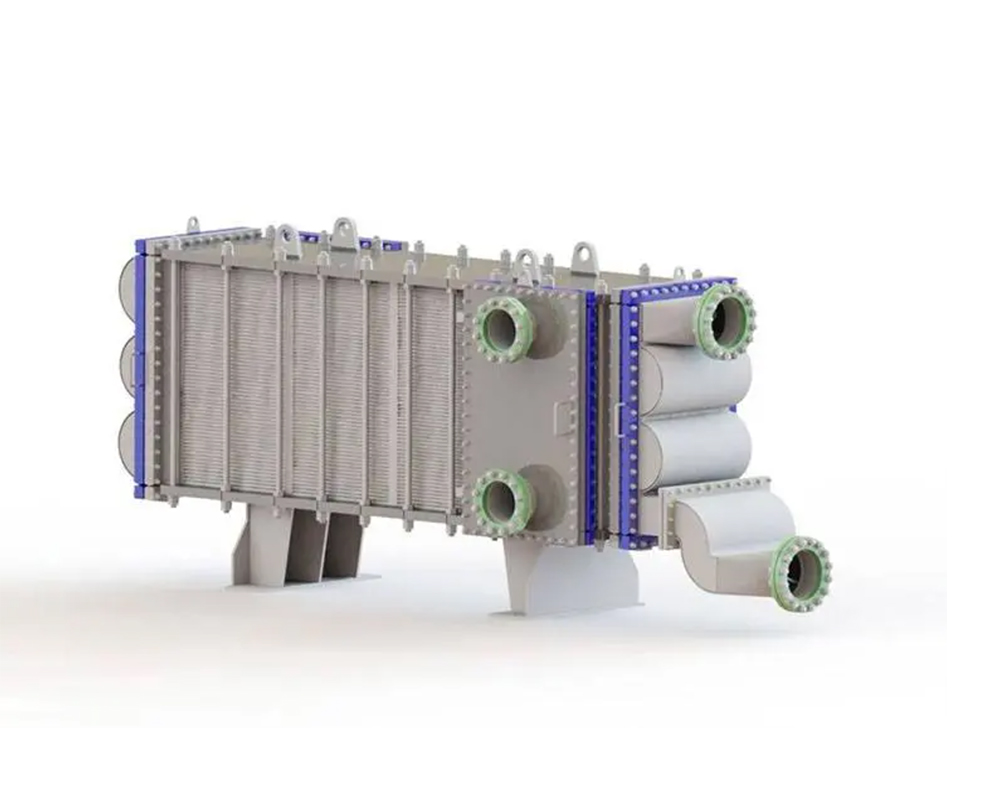

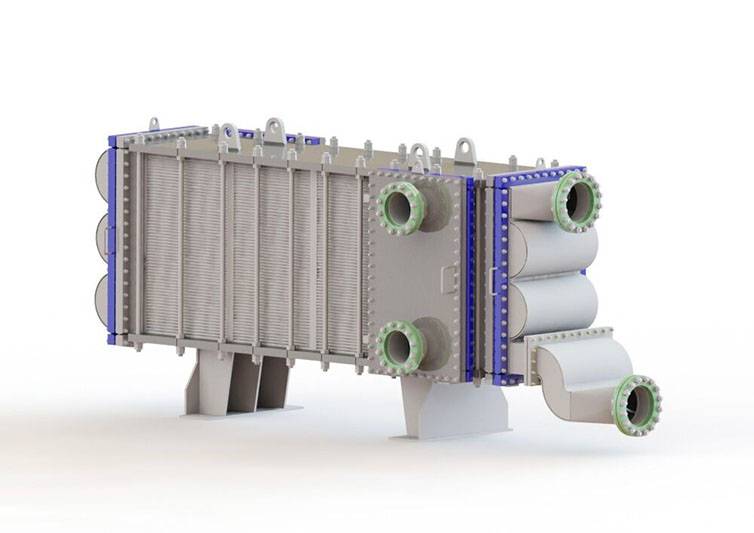

1. Horizontal structure, High flow rate brings the slurry which contains solid particles to flow on the surface of plate and effectively refraining the sedimentation and scar.

2. The wide channel side has no touching point so that the liquid can flow freely and completely in flow path formed by the plates. Almost all the plate surfaces are involved in the heat exchange, which realizes the flow of no ”Dead spots” in the flow path.

3. There is distributor in the slurry inlet, which makes the slurry enter the path uniformly and reduces erosion.

4. Plate material: Duplex steel and 316L.

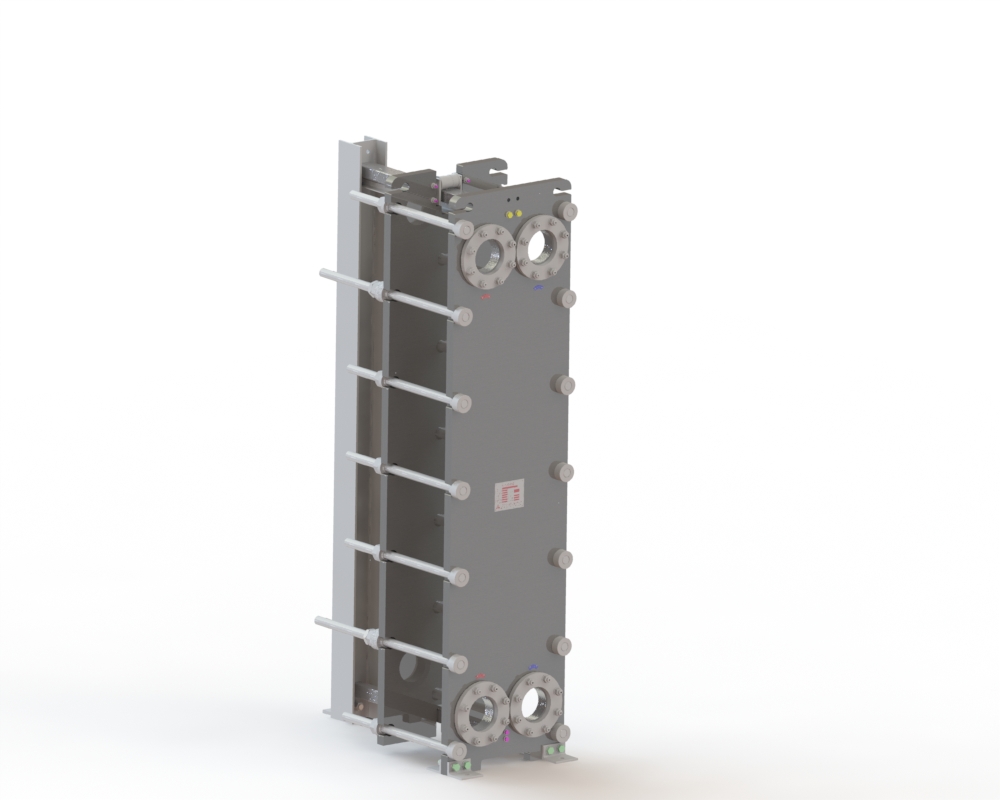

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

No matter new shopper or old customer, We believe in very long expression and dependable relationship for Professional China Compact Heat Exchanger - Horizontal Precipitation Slurry Cooler in Alumina Refinery – Shphe , The product will supply to all over the world, such as: Holland , Bangalore , Barcelona , Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.