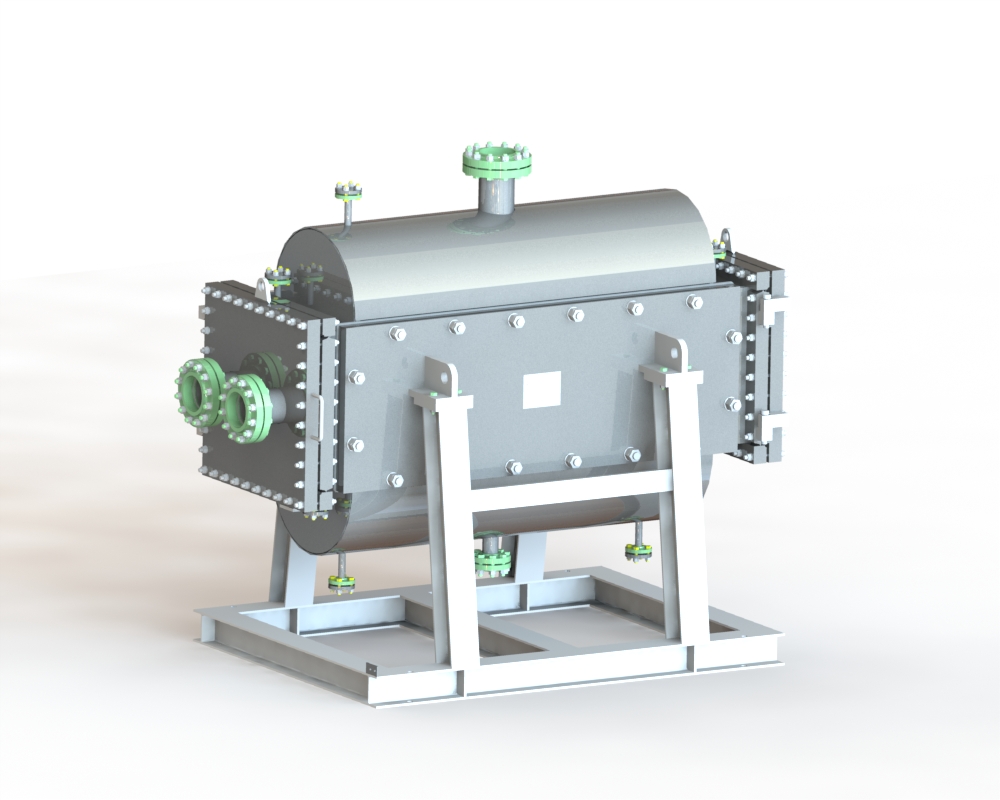

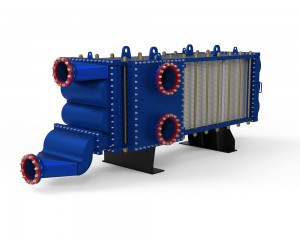

Openable TP Fully Welded Plate Heat Exchanger

How it works

TP fully welded plate heat exchanger is a kind of widely applied heat exchange equipment which combines characteristics of plate heat exchanger and tubular heat exchanger. It has the benefit of plate heat exchanger such as high heat transfer efficiency and compact structure, and the advantage of tubular heat exchanger like high press. and high temp. resistance and safe and reliable.

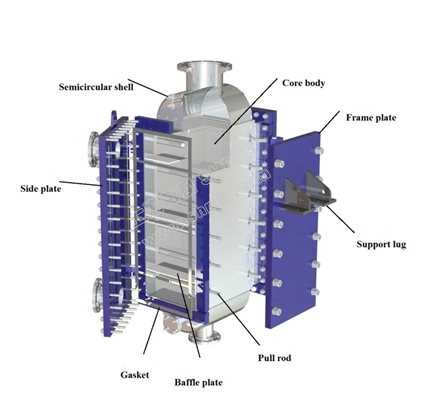

The main components of TP fully welded plate heat exchanger: one or multiple plate pack, frame plate, clamping bolts, plate side shell, tube side shell, inlet and outlet connection of cold and hot side, baffle plate and structure, etc. The corrugated plates stacked and welded together to form plate pack, the dimension of plate pack varies depending on different plate length and no. of plates.

The tube side shell and plate side shell can be either welded or bolted depending on process condition.

Features

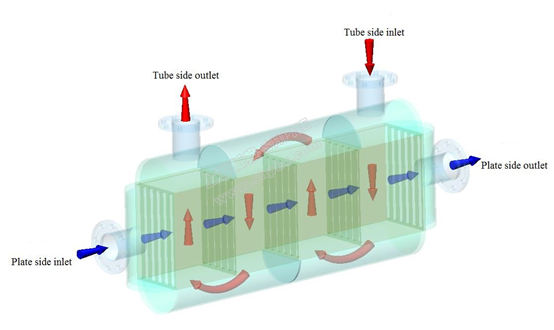

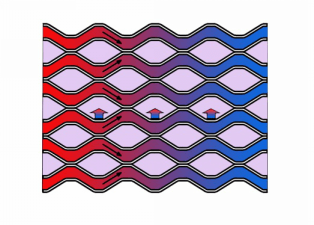

☆ The unique designed plate corrugation form plate channel and tube channel. Two plates stacked to form sine shaped corrugated plate channel, the plate pairs stacked to form elliptically tube channel.

☆ Turbulent Flow in plate channel results high heat transfer efficiency, while tube channel has the feature of small flow resistance and high press. resistant.

☆ Fully welded structure, safe and reliable, suitable for high temp., high press. and hazardous application.

☆ No dead area of flowing, removable structure of tube side facilitate mechanical cleaning.

☆ As condenser, super cooling temp. of steam can be well controlled.

☆ Flexible design, multiple structures, can meet requirement of various process and installation space.

☆ Compact structure with small footprint.

Flexible flow pass configuration

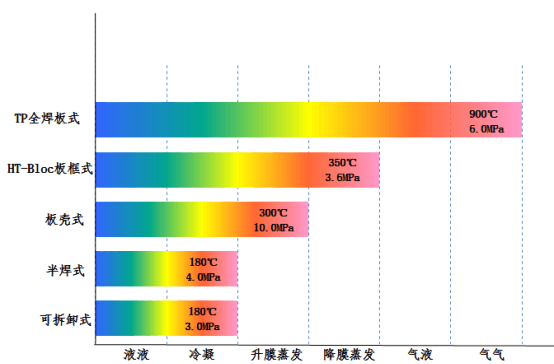

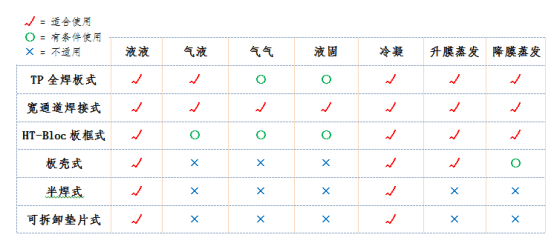

Range of application

Variable structure

Application

☆ Oil refinery

● Crude oil heater, condenser

☆ Oil & gas

● Desulfurization, decarburization of natural gas – lean/rich amine heat exchanger

● Dehydration of natural gas – lean / rich amine exchanger

☆ Chemical

● Process cooling / condensing / evaporation

● Cooling or heating of various chemical substances

● MVR system evaporator, condenser, pre-heater

☆ Power

● Steam condenser

● Lub. Oil cooler

● Thermal oil heat exchanger

● Flue gas condensing cooler

● Evaporator, condenser, heat regenerator of Kalina cycle, Organic Rankine Cycle

☆ HVAC

● Basic heat station

● Press. isolation station

● Flue gas condenser for fuel boiler

● Air dehumidifier

● Condenser, evaporator for refrigeration unit

☆ Other industry

● Fine chemical, coking, fertilizer, chemical fiber, paper & pulp, fermentation, metallurgy, steel, etc.