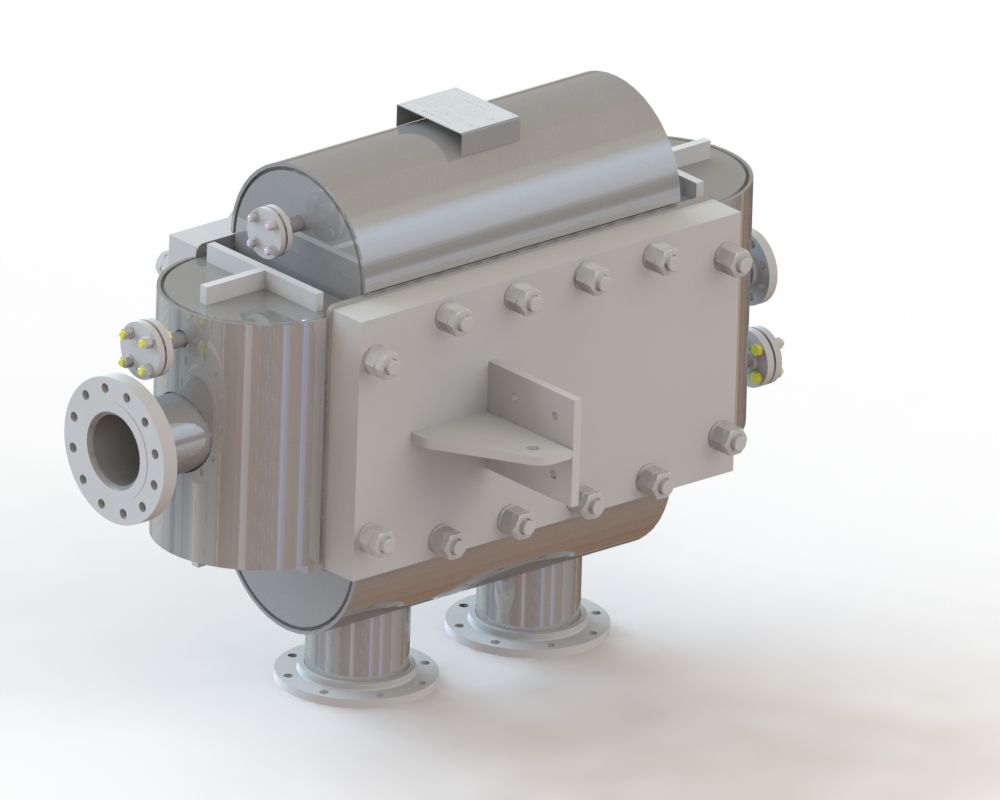

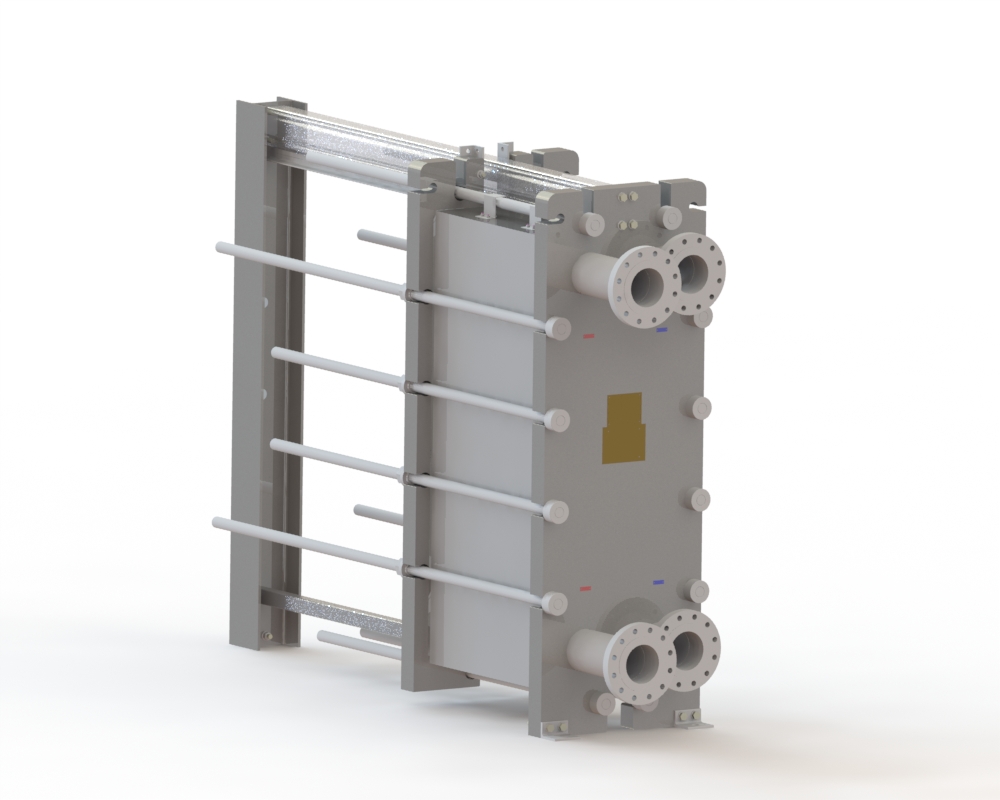

OEM/ODM Manufacturer Full Weld Phe In Hydrogen Peroxide Plant - Plate Heat Exchanger with flanged nozzle – Shphe

OEM/ODM Manufacturer Full Weld Phe In Hydrogen Peroxide Plant - Plate Heat Exchanger with flanged nozzle – Shphe Detail:

How Plate Heat Exchanger works?

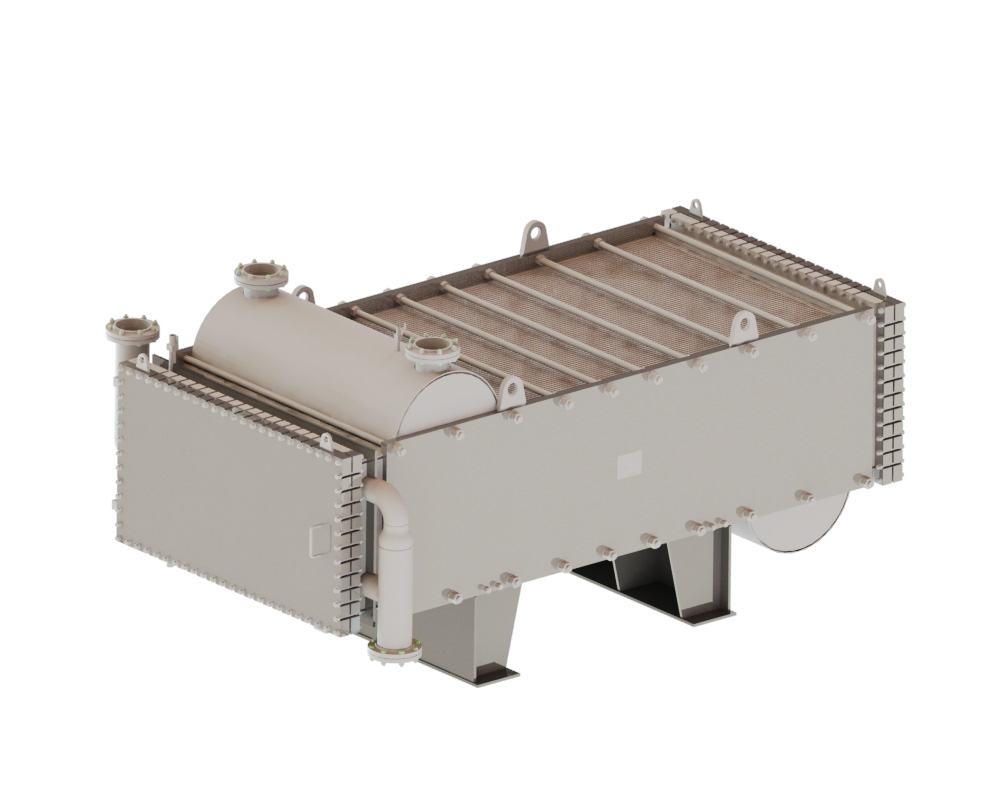

Plate Type Air Preheater

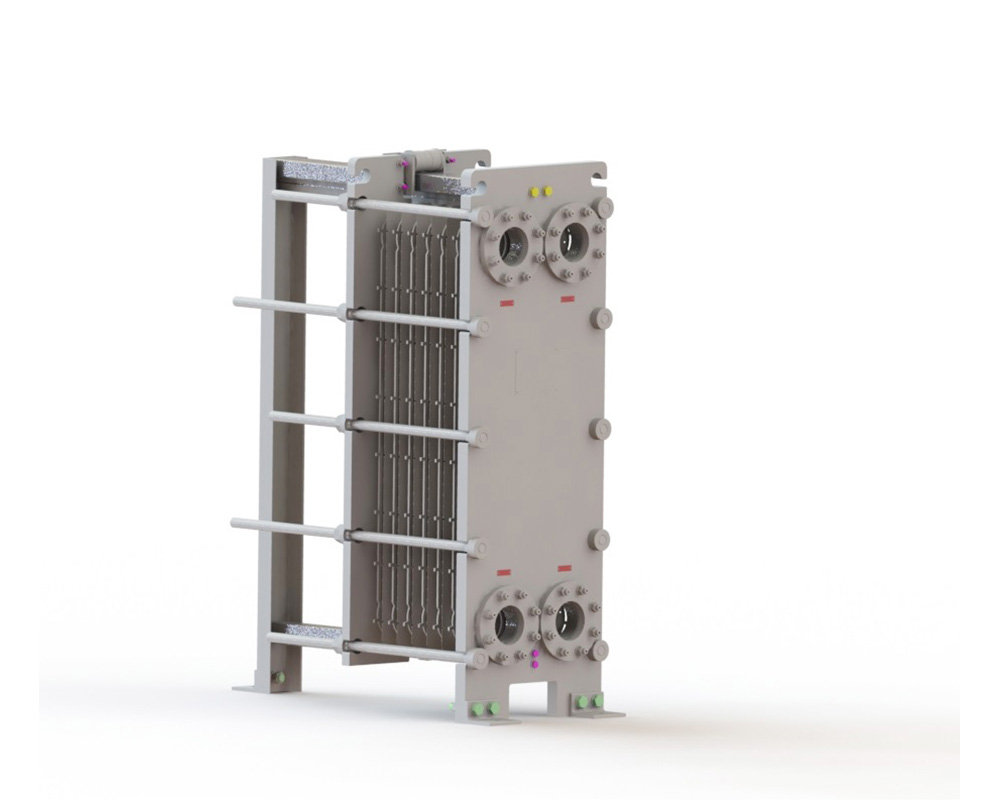

Plate Heat Exchanger is composed of many heat exchange plates which are sealed by gaskets and tightened together by tie rods with locking nuts between frame plate. The medium runs into the path from the inlet and is distributed into flow channels between heat exchange plates. The two fluids flow countercurrent in the channel, the hot fluid transfers heat to the plate, and the plate transfers heat to the cold fluid on the other side. Therefore the hot fluid is cooled down and the cold fluid is warmed up.

Why plate heat exchanger?

☆ High heat transfer coefficient

☆ Compact structure less foot print

☆ Convenient for maintenance and cleaning

☆ Low fouling factor

☆ Small end-approach temperature

☆ Light weight

☆ Small footprint

☆ Easy to change surface area

Parameters

| Plate thickness | 0.4~1.0mm |

| Max. design pressure | 3.6MPa |

| Max. design temp. | 210ºC |

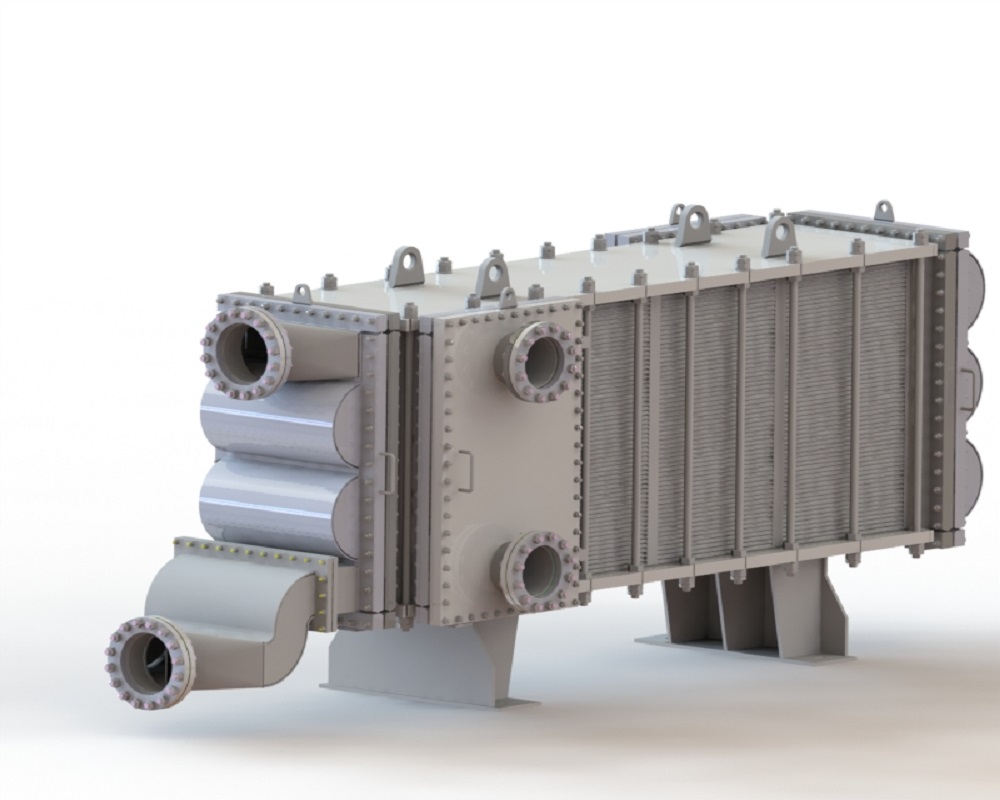

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for OEM/ODM Manufacturer Full Weld Phe In Hydrogen Peroxide Plant - Plate Heat Exchanger with flanged nozzle – Shphe , The product will supply to all over the world, such as: UK , Liverpool , Bolivia , Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part solutions. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!