Welded plate heat exchangers are pivotal components in various industrial processes, offering efficient thermal management solutions. This article delves into the intricacies of welded plate heat exchangers, exploring their design, advantages, operational mechanisms, and diverse applications. By understanding these elements, professionals can make informed decisions to optimize their thermal systems effectively.

What is a Welded Plate Heat Exchanger?

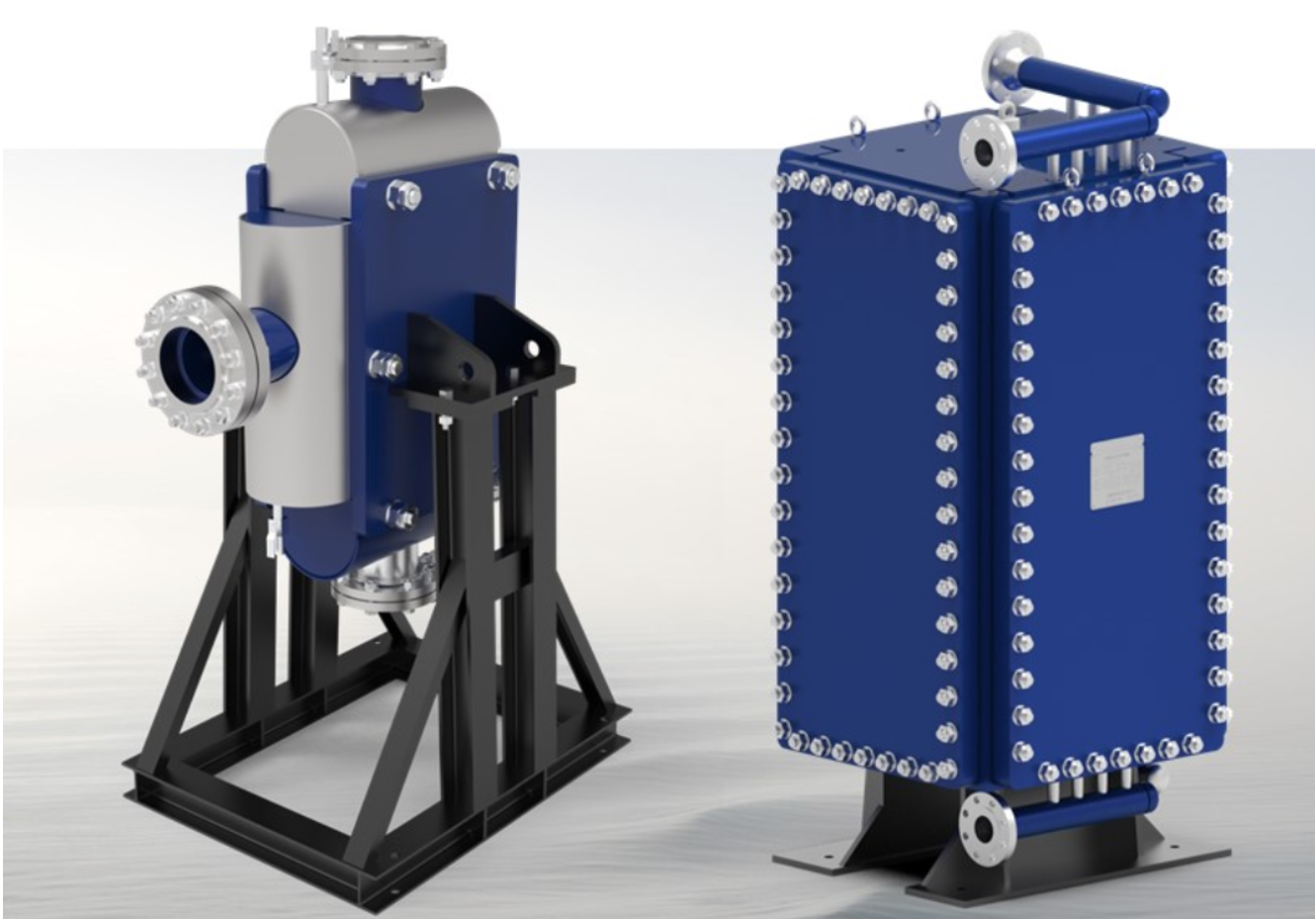

A welded plate heat exchanger (WPHE) is a type of heat exchanger that utilizes multiple thin, corrugated plates welded together to facilitate efficient heat transfer between two fluids. Unlike traditional shell-and-tube heat exchangers, WPHEs offer enhanced thermal performance, compact design, and versatility in handling different fluid types.

Key Components of a Welded Plate Heat Exchanger

1.Corrugated Plates: These plates have intricate patterns that increase the surface area for heat exchange, promoting efficient thermal transfer.

2.Welding: Depending on the design, plates welded to prevent fluid leakage and ensure durability.

3.Frame and End Covers: The assembly is housed within a robust frame or shell, with end covers facilitating fluid entry and exit.

4.Sealing Mechanism: Ensures that the two fluids remain separated, preventing cross-contamination.

Design and Construction of Welded Plate Heat Exchangers

The design of WPHEs is crucial for their performance and longevity. Key design considerations include:

Plate Configuration

● Corrugation Patterns: The design of the plate corrugations affects fluid flow and heat transfer efficiency. Common patterns include Chevron, Wave, and Herringbone.

● Plate Thickness: Thinner plates offer higher heat transfer rates but require precise manufacturing to maintain structural integrity.

Material Selection

● Stainless Steel: Preferred for its corrosion resistance and durability, especially in harsh environments.

● Titanium: Used in applications requiring superior corrosion resistance, such as in seawater systems.

● Nickel Alloys: Selected for high-temperature applications due to their excellent thermal conductivity.

Welding Techniques

● Fusion Welding: Ensures a seamless connection between plates, eliminating potential leakage points.

● Resistance Welding: Utilized for joining plates efficiently, especially in high-volume production scenarios.

Thermal Design

● Heat Transfer Coefficients: Optimized through plate design to maximize thermal exchange.

● Flow Arrangement: Configured for counterflow or parallel flow to enhance heat transfer efficiency.

Advantages of Welded Plate Heat Exchangers

Welded plate heat exchangers offer numerous benefits that make them a preferred choice in various industries:

High Thermal Efficiency

The intricate plate design and increased surface area facilitate superior heat transfer rates compared to traditional heat exchangers.

Compact and Lightweight

WPHEs have a smaller footprint, making them ideal for installations with space constraints.

Versatility

Suitable for a wide range of fluids, including corrosive and high-temperature liquids, enhancing their applicability across different sectors.

Easy Maintenance

Modular design allows for straightforward cleaning and maintenance, minimizing downtime and operational disruptions.

Durability and Reliability

Welded construction ensures robust performance and longevity, even under demanding conditions.

Operational Mechanism of Welded Plate Heat Exchangers

Understanding the operational principles of WPHEs is essential for optimizing their performance:

Fluid Flow Dynamics

WPHEs operate by directing two separate fluids through alternate channels formed by the corrugated plates. The corrugations induce turbulence, enhancing heat transfer efficiency by disrupting the boundary layer.

Heat Transfer Process

Heat is transferred from the hotter fluid to the cooler fluid through the plate material. The efficiency is influenced by factors such as plate surface area, fluid velocities, and temperature gradients.

Pressure Drop Considerations

While WPHEs offer high thermal efficiency, they can experience higher pressure drops due to the corrugated plate design. Proper system design and fluid dynamics analysis are essential to mitigate this effect.

Applications of Welded Plate Heat Exchangers

Welded plate heat exchangers are utilized across various industries due to their efficiency and versatility:

Chemical Processing

Used for heat recovery, temperature control, and reaction heating, WPHEs handle corrosive chemicals effectively.

Food and Beverage

Ensures precise temperature control during processing and packaging, maintaining product quality and safety.

Power Generation

Employed in cooling systems and waste heat recovery, contributing to overall energy optimization.

Oil and Gas Industry

Handles high-temperature and high-pressure fluids, ensuring reliable performance in demanding environments.

Maintenance and Troubleshooting

Regular maintenance is vital to ensure the optimal performance of welded plate heat exchangers. Key maintenance practices include:

Routine Inspections

Check for signs of corrosion, leaks, and plate damage to address issues proactively.

Cleaning Procedures

Implement regular cleaning protocols to remove fouling and scaling, maintaining heat transfer efficiency.

Pressure Testing

Conduct pressure tests to verify the integrity of welds and seals, preventing potential leaks.

Troubleshooting Common Issues

● Reduced Heat Transfer Efficiency: Often caused by fouling or scaling; regular cleaning can mitigate this.

● Increased Pressure Drop: May result from blocked channels or damaged plates; inspecting and replacing affected plates can resolve this.

● Leaks: Typically due to faulty welds or seals; identifying and repairing leaks promptly is essential to maintain system integrity.

Future Trends in Welded Plate Heat Exchanger Technology

Advancements in materials and manufacturing techniques are driving the evolution of WPHEs:

Enhanced Materials

Development of new alloys and composite materials offers improved corrosion resistance and thermal performance.

Smart Monitoring Systems

Integration of IoT, AI and sensor technologies enables real-time monitoring and predictive maintenance, enhancing operational efficiency.

Energy-Efficient Designs

Innovations in plate geometry and flow dynamics aim to further increase thermal efficiency while reducing energy consumption.

Sustainable Manufacturing

Adoption of eco-friendly manufacturing processes aligns with global sustainability goals, reducing the environmental impact of WPHE production.

Conclusion

Welded plate heat exchangers are indispensable in modern industrial applications, offering high thermal efficiency, compact design, and versatility. Understanding their design, advantages, operational mechanisms, and maintenance requirements enables industries to leverage their full potential, ensuring optimal performance and reliability. As technology continues to advance, WPHEs will play an increasingly critical role in sustainable and efficient thermal management solutions.

Post time: Feb-21-2025