Plate Heat Exchanger in Brief

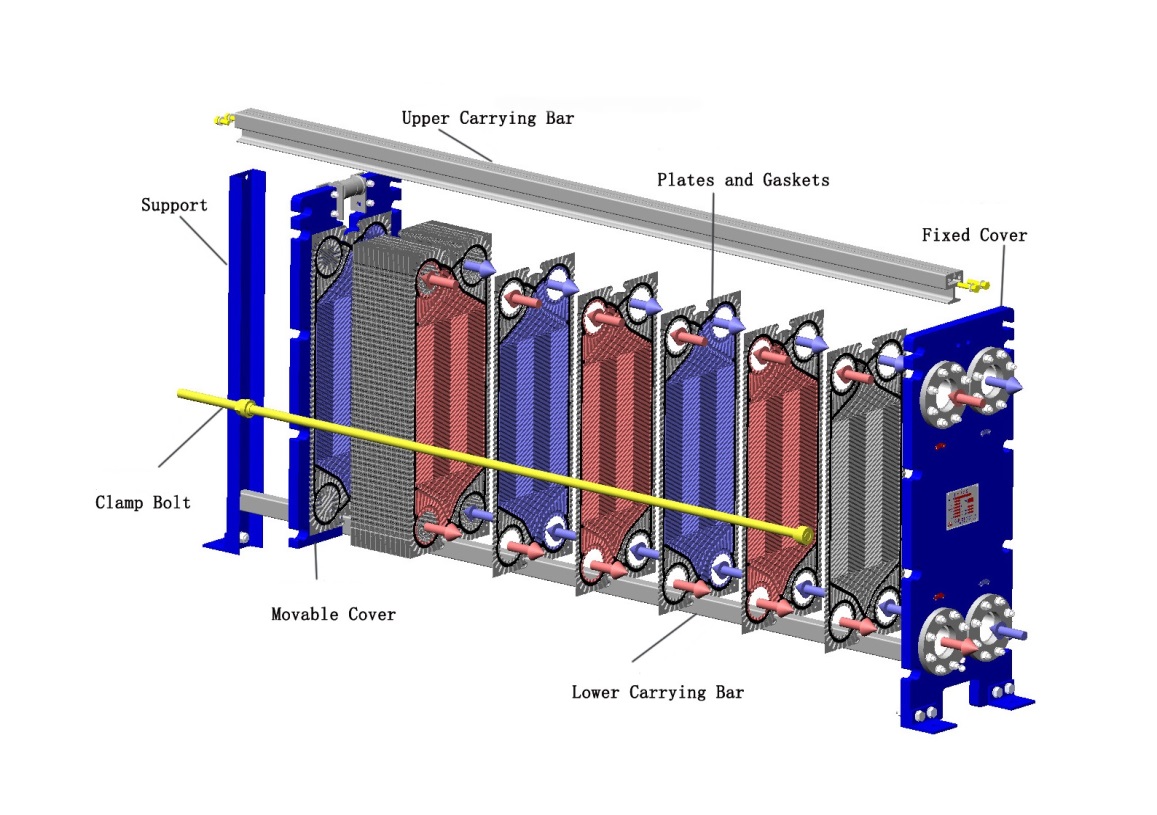

Plate Heat Exchanger is composed of many heat exchange plates which are sealed by gaskets and tightened together by tie rods with locking nuts between frame plate. The medium runs into the path from the inlet and is distributed into flow channels between heat exchange plates. The two fluids flow countercurrent in the channel, the hot fluid transfers heat to the plate, and the plate transfers heat to the cold fluid on the other side. Therefore the hot fluid is cooled down and the cold fluid is warmed up.

Compared with shell and tube heat exchangers, Plate heat exchanger are the compact, modern equipment with significantly better thermal efficiency and by far the greatest technology development potential.

However, Plate heat exchanger manufacturers know that pressure is a major bottleneck in plate technology of today, to achieve higher design pressure capabilities, Shanghai Heat Transfer Equipment Co.,Ltd., developed DUPLATE™ plate, provided a better solution for modern process industry, which can heat and cool a wide range of substances.

What is DUPLATE™

·DUPLATE™ plate means the plate material is formable duplex stainless steel. It’s a patented product of Shanghai Heat Transfer Equipment Co.,Ltd.

·DUPLATE™ plate is cold pressed with unique technology, In combination with special gasket and frame.

·Design pressure is up to 36bar. It breaks the bottleneck of material selection of conventional plate heat exchanger, initially realized commercialized production of plate in duplex stainless steel.

Why Choose DUPLATE™

·With high strength and high yield feature, the deformation problem of fluid channel with conventional plate heat exchanger at higher pressure was solved. More stable medium flowing and higher heat transfer efficiency is achieved.

·DUPLATE™ plate combines the corrosion resistance of both ferritic and austenitic steel grade, which extended application scope of regular austenitic stainless steel plate. Especially in process where medium contains chloride or sulphide at high temp., the regular austenitic stainless steel plate is prone to stress corrosion crack (SCC), while DUPLATE™ plate has better resistance.

·The surface hardness of DUPLATE™ plate is high, applicable to process which contain particles or prone to erosion.

·DUPLATE™ plate has good fatigue resistance, especially applicable to process that has frequent pressure or heat load vibration .

·More thinner plate will be available now for same pressure rating condition. Meanwhile, as the alloy content in DUPLATE™ plate is low, the consumption of alloy material is reduced, therefore more cost-effective solution is possible.

Applications of DUPLATE™

·District heating and cooling, ice cold storage

·HVAC – cold air conditioning for high buildings, pressure heat exchanger station

·Metallurgy – Steel, alumina, lead and zinc, copper refinery

·Chemical – Chlorine and caustic soda, polyester, resin, rubber, fertilizer, glycol, Sulphur removal, carbon removal

·Machinery – Hydraulic station, lub. Oil system, metal machining, engine, reducer, metal machining

·Paper & pulp – Waste water treatment, black liquor preheating, heat recovery

·Fermentation – Fuel ethanol, citric acid, sorbitol, fructose

·Food – Sugar, edible oil, dairy, starch

·Energy – Thermal power, hydropower, wind power, Oil Refinery, nuclear power

Post time: Dec-02-2020