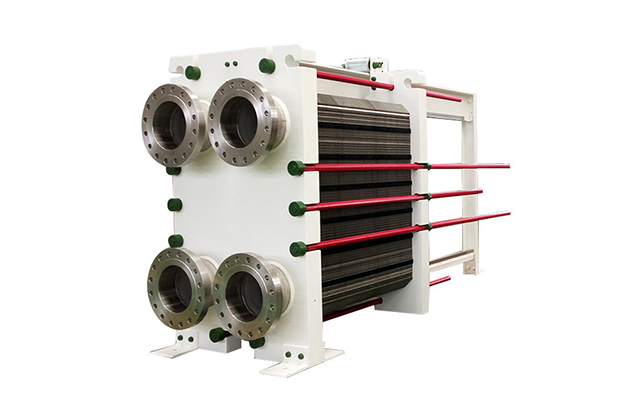

Plate heat exchanger is an efficient and reliable heat exchanger, widely used in chemical, petroleum, heating and other industries. But how to design a plate heat exchanger?

Designing a plate heat exchanger involves several key steps, including selecting the appropriate design, determining the heat duty, calculating the pressure drop, and selecting the appropriate materials.

1 、Select the appropriate design type: The design of the plate heat exchanger will depend on the specific requirements of the application, such as the temperature and flow rate of the fluids, the desired heat duty, and the available space. The most common types of plate heat exchangers are gasketed, brazed and welded plate heat exchangers.

2 、Determine the heat duty: The heat duty is the amount of heat transferred between the two fluids in the plate heat exchanger. This can be calculated using the heat transfer coefficient, the heat transfer area, and the temperature difference between the two fluids.

3 、Calculate the pressure drop: The pressure drop is the loss of pressure that occurs as the fluid flows through the plate heat exchanger. This can be calculated using the friction factor, the length of the flow path, and the flow rate.

4 、Select the appropriate materials: The materials used in the plate heat exchanger will depend on the specific application, such as the temperature and chemical compatibility of the fluids. The most common materials are stainless steel, titanium, and nickel alloys.

5、 Verify the design: Once the initial design is completed, it is important to verify the design using simulation or experimental testing to ensure that the plate heat exchanger meets the desired heat transfer rate and pressure drop.

Shanghai Heat Transfer Equipment Co., Ltd. provide comprehensive solutions to customers with optimal design and after-sales attentive service. We will continue to work hard to provide customers with more quality products and services to achieve win-win results.

Post time: Mar-01-2023