1. Mechanical cleaning

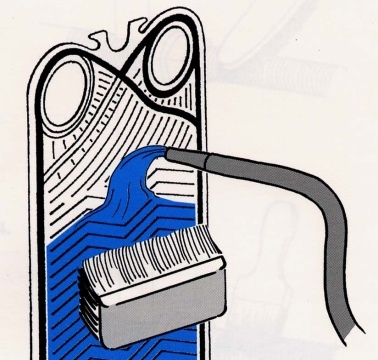

(1)Open the cleaning unit and brush the plate.

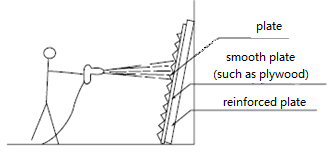

(2)Clean the plate with high pressure water gun.

Please Note:

(1) EPDM gaskets shall not contact with aromatic solvents over half an hour.

(2) The back side of the plate cannot touch the ground directly when cleaning.

(3) After water cleaning, check carefully the plates and gaskets and no residua such as solid particles and fibers left on the plate surface are allowed. The peeled off and damaged gasket shall be glued or replaced.

(4) When conducting the mechanical cleaning, metal brush is not allowed to use to avoid scratching plate and gasket.

(5) When cleaning with high pressure water gun, the rigid plate or reinforced plate must be used to support the plate back side (this plate shall be contacted fully with the heat exchange plate) to prevent from deformation, the distance between nozzle and exchange plate shall not be less than 200 mm, the max. injection pressure is not greater than 8Mpa; Meantime, the collection of water shall pay attention if using the high pressure water gun to avoid contaminating at site and other equipment.

2 Chemical cleaning

For the ordinary fouling, according to its properties, alkali agent with mass concentration less than or equal to 4% or acid agent with mass concentration less than or equal to 4% can be used for cleaning, the cleaning process is:

(1)Cleaning temperature:40~60℃。

(2)Back flushing without disassembly of the equipment.

a) Connect a pipe at the media inlet and outlet pipeline in advance;

b) Connect the equipment with “mechanic cleaning vehicle”;

c) Pump the cleaning solution into the equipment in the opposite direction as the usual product flow;

d) Circulate cleaning solution 10~15 minutes at media flow rate of 0.1~0.15m/s;

e) Finally re-circulate 5~10 minutes with clean water. Chloride content in the clean water shall be less than 25ppm.

Please Note:

(1) If this cleaning method is adopted, the spare connection shall be remained before assembly to have the cleaning fluid been drained off smoothly.

(2) Clean water shall be used for flushing the heat exchanger if the back flush is carried out.

(3) Special cleaning agent shall be used for cleaning of special dirt based on the specific cases.

(4)The mechanical and chemical cleaning methods can be used in combination with each other.

(5)No matter which method is adopted, the hydrochloric acid is not allowed to clean the stainless steel plate. Water of more than 25 ppm chlorion content may not be used for the preparation of cleaning fluid or flush stainless steel plate.

Post time: Jul-29-2021