Manufacturer for Heat Exchanger Design - All Welded Bloc Plate Heat Exchanger – Shphe

Manufacturer for Heat Exchanger Design - All Welded Bloc Plate Heat Exchanger – Shphe Detail:

What is HT-Bloc?

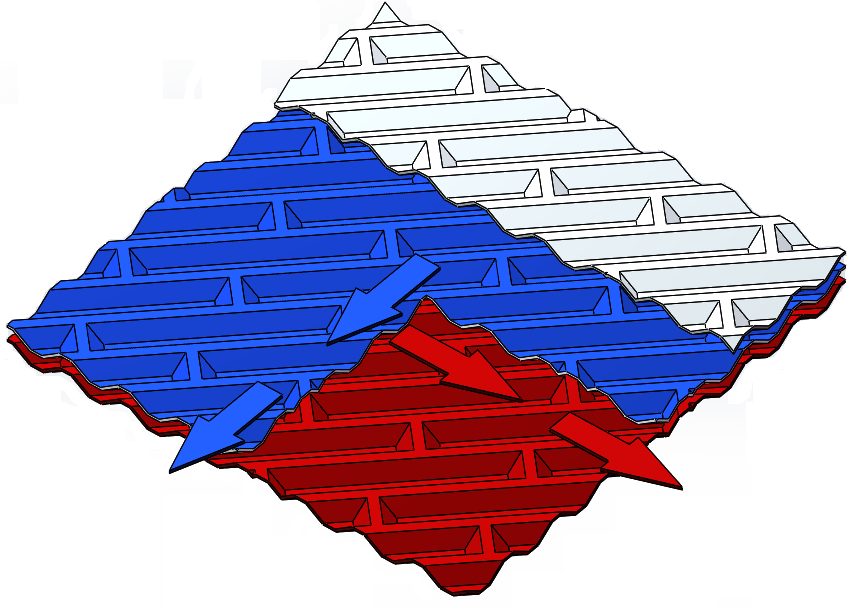

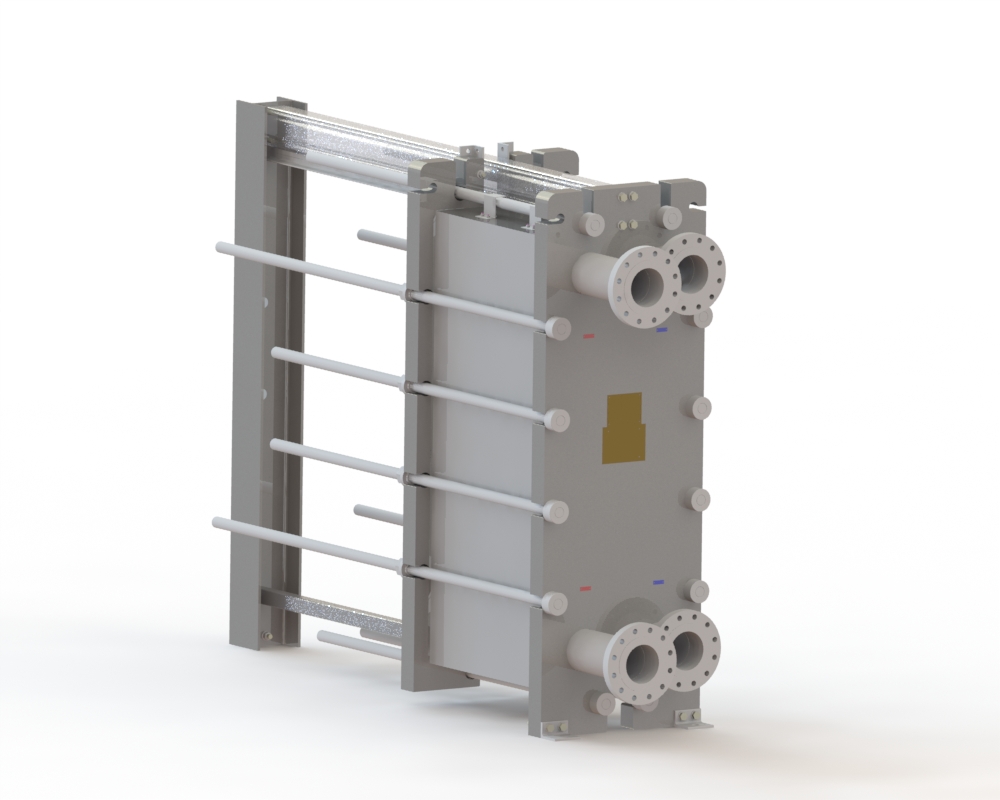

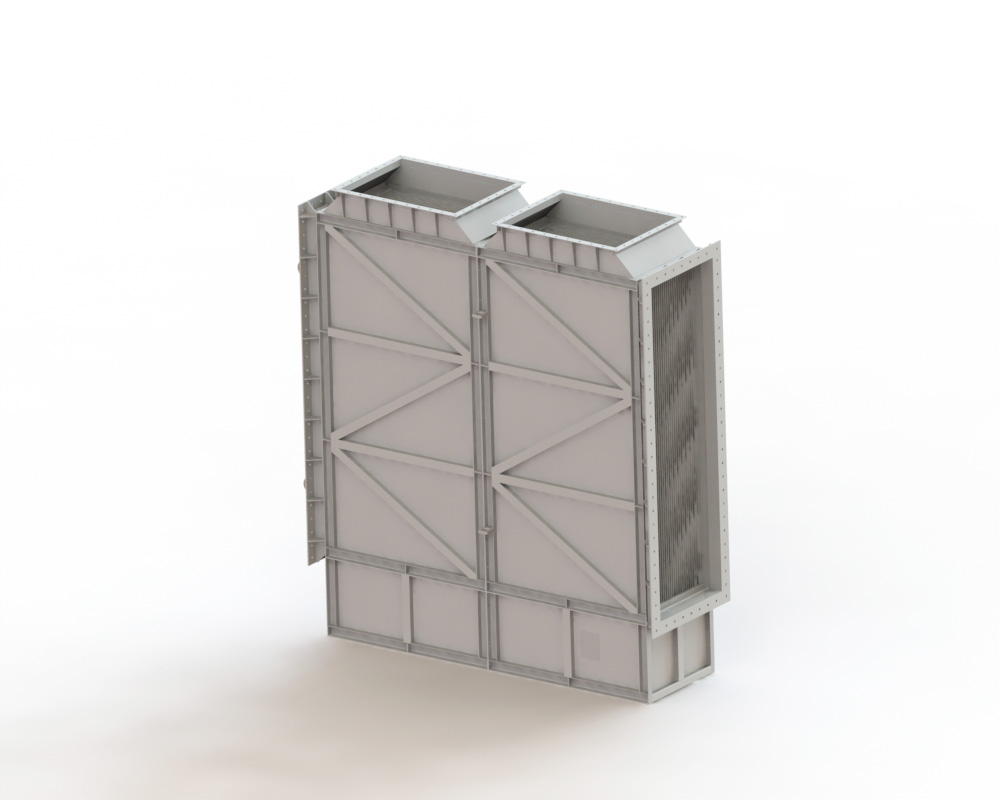

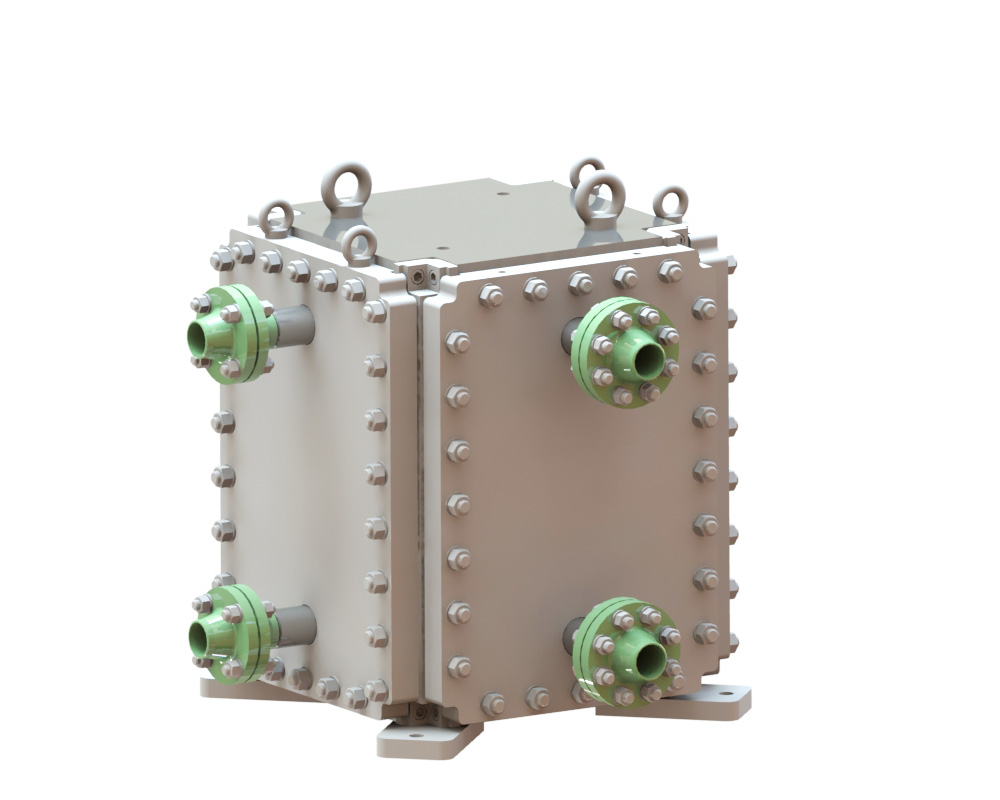

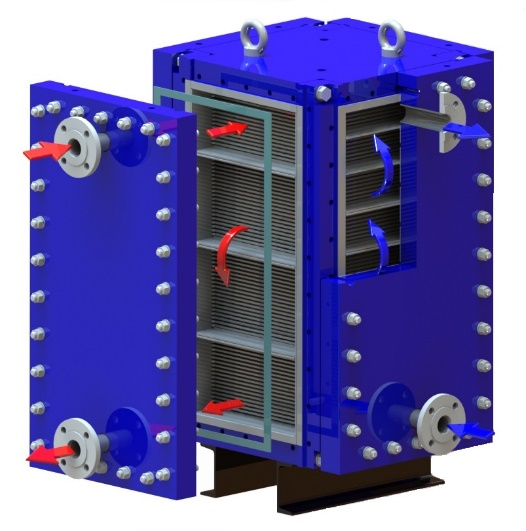

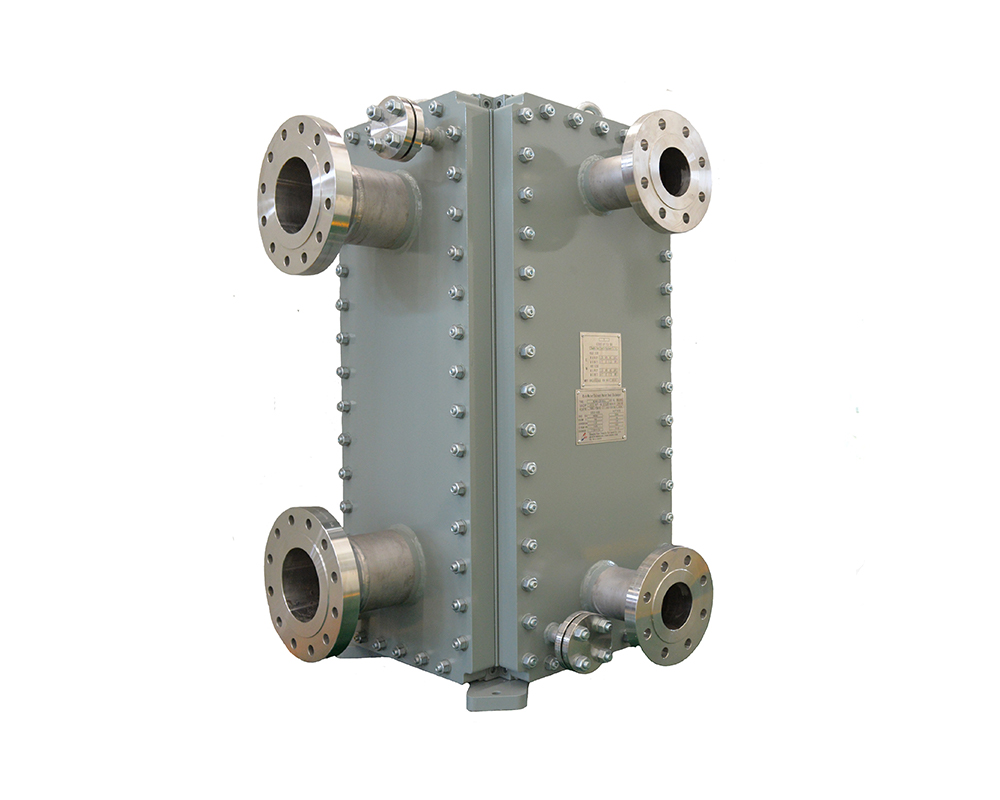

HT-Bloc plate heat exchanger is made up of plate pack and frame. The plate pack is certain number of plates welded together to form channels, then it is installed into a frame, which is formed by four corner girders, top and bottom plates and four side panels. The frame is bolted connected and can be easily disassembled for service and cleaning. There are three different plate patterns, corrugated, studded, and dimpled pattern, to meet different process requirements.

Why All Welded Bloc Plate Heat Exchanger?

1.Corrugated plate type. High heat transfer efficiency & good pressure-bearing,suitable for clean medium at both sides.

2.Cross flow for one pass HE, countercurrent flow for multiple pass HE to guarantee heat transfer.)

3.Plate pack is fully welded without gaskets.

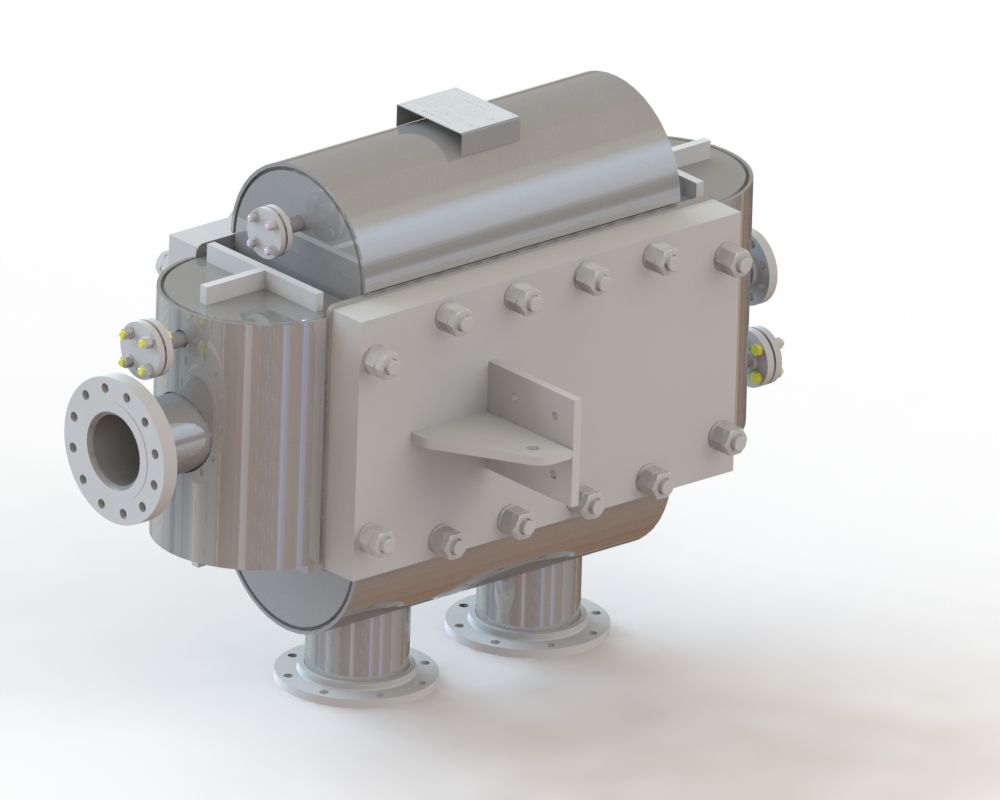

4.Suitable for high temp., high pressure and corrosive process.

5.Flexible flow pass design

6.Different flow pass number at hot and cold side can ensure high heat transfer efficiency at both sides. Pass arrangement can be easily adjusted according to new process requirement.

7.Compact structure and small footprint

8.Frame can be disassembled to facilitate repair & cleaning.

Applications

☵ Refinery

Pre-heating of crude oil

Condensation of gasoline, kerosene, diesel, etc.

☵ Natural gas

Gas sweetening, decarburization ——lean/rich solvent service

Gas dehydration —— heat recovery in TEG systems

☵ Refined oil

Crude oil sweetening —— edible oil heat exchanger

☵ Coke over plants

Ammonia liquor scrubber cooling

Benzoilzed oil heating, cooling

☵ Refine sugar

mixed juice, fumigated juice heating

Pressure mooring juice heating

☵ Pulp and paper

Heat recovery of boil and fumigation

Heat recovery of bleaching process

Washing liquid heating

☵ Fuel ethanol

Lees liquid to fermented liquid heat exchange

Pre-heating of ethanol solution

☵ Chemicals, Metallurgy, Fertilizer production, Chemical fiber, Water treatment plant, etc.

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Manufacturer for Heat Exchanger Design - All Welded Bloc Plate Heat Exchanger – Shphe , The product will supply to all over the world, such as: India , Algeria , Oman , Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.