Factory directly supply Thermal Transfer Heat Exchanger - All Welded Bloc Plate Heat Exchanger – Shphe

Factory directly supply Thermal Transfer Heat Exchanger - All Welded Bloc Plate Heat Exchanger – Shphe Detail:

What is HT-Bloc?

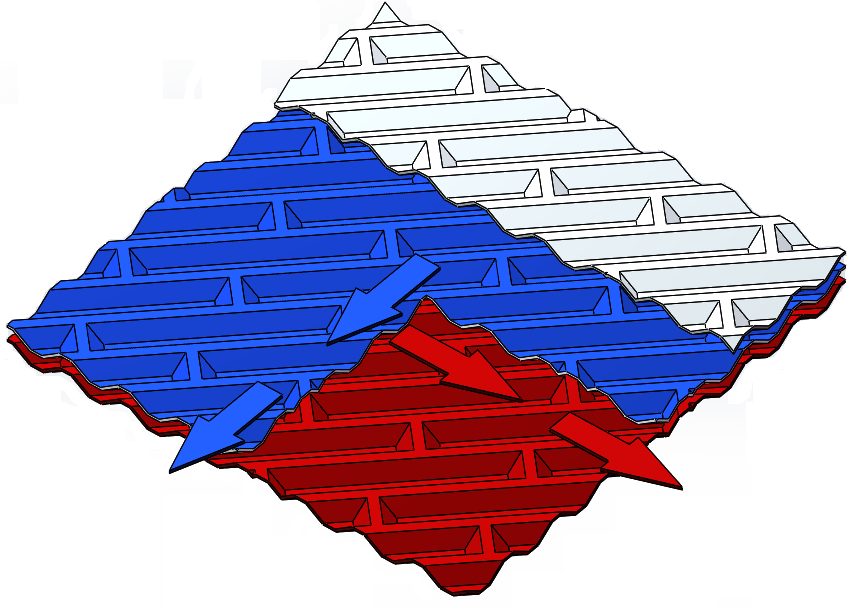

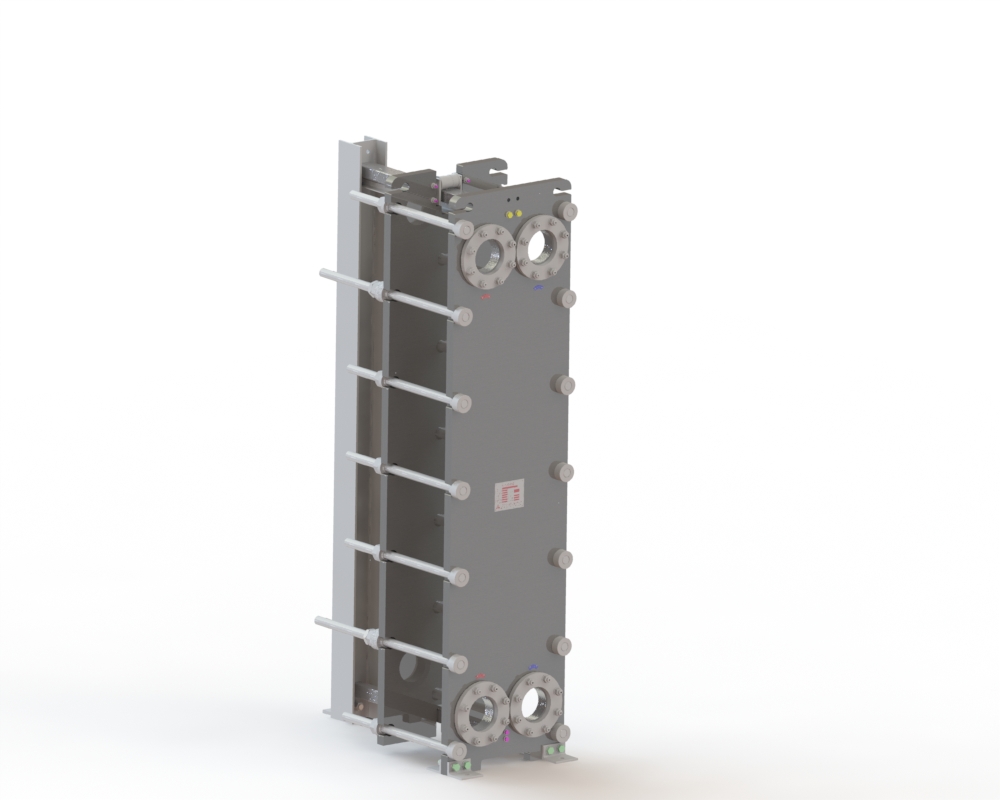

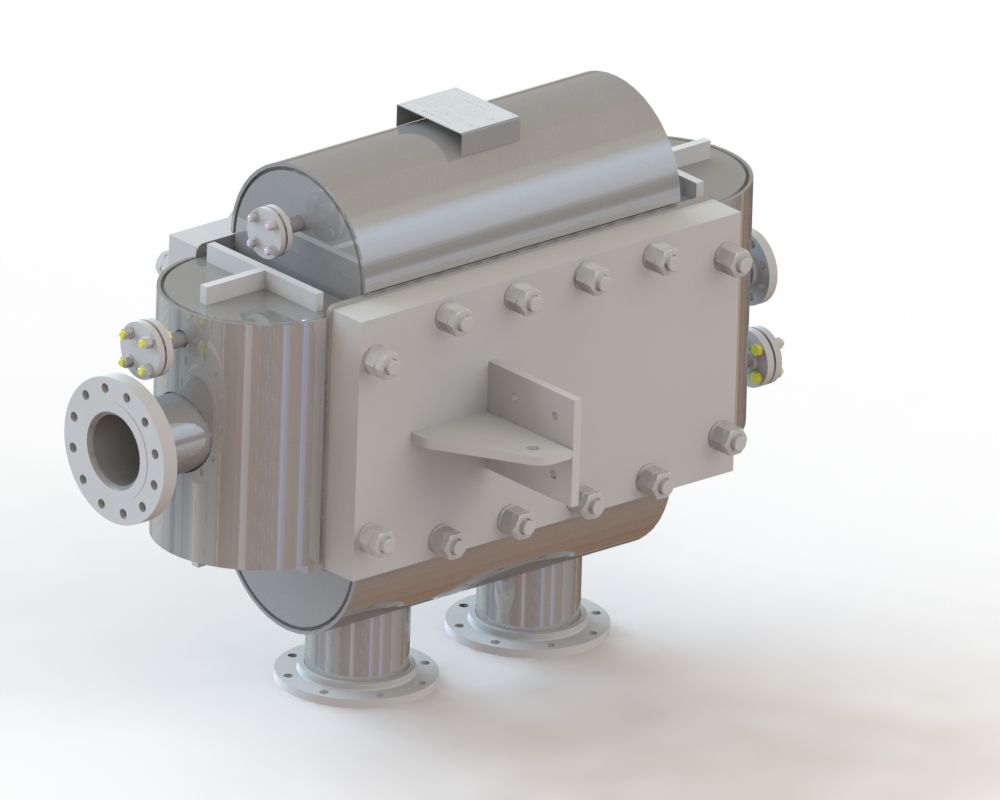

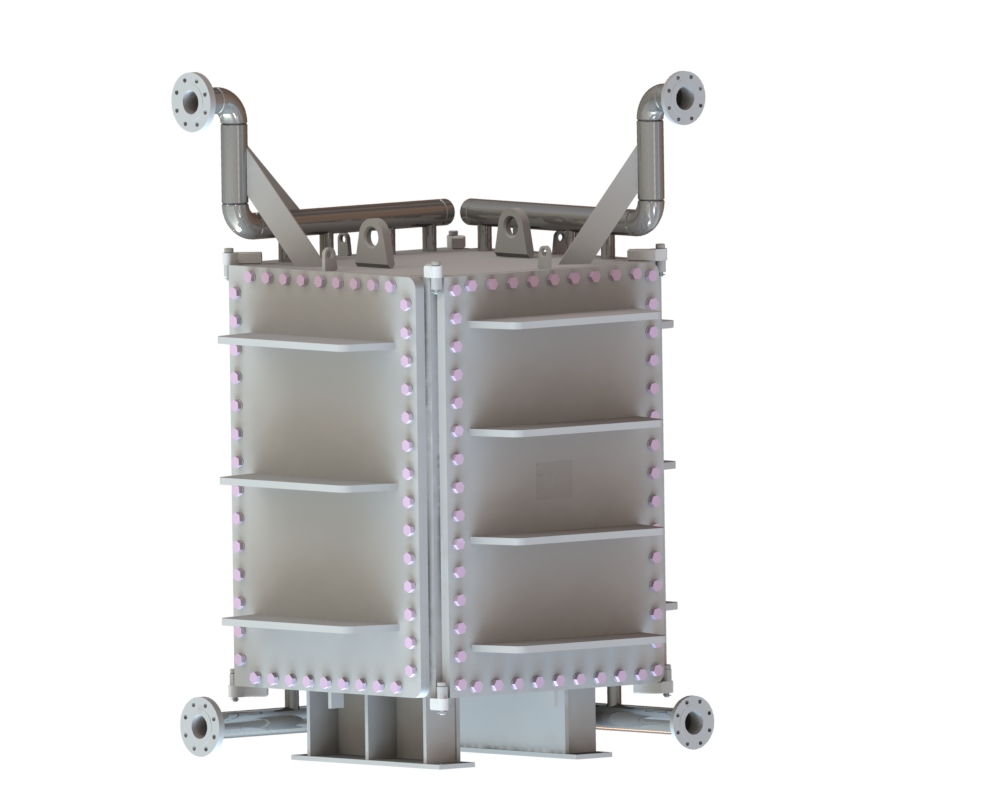

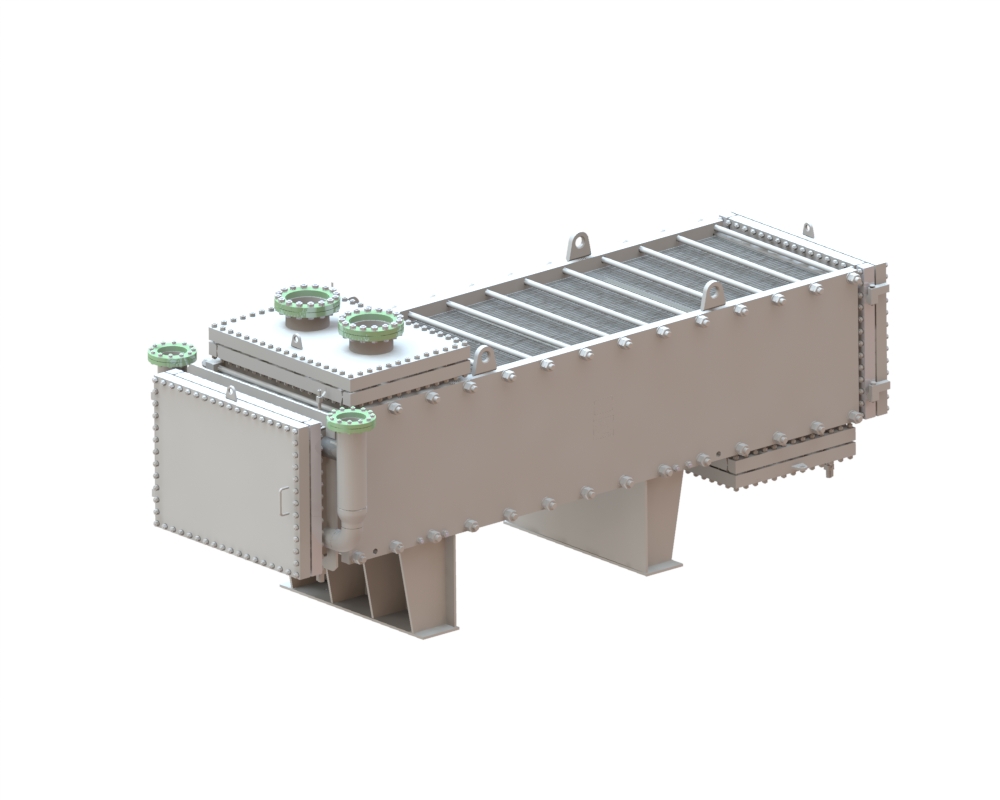

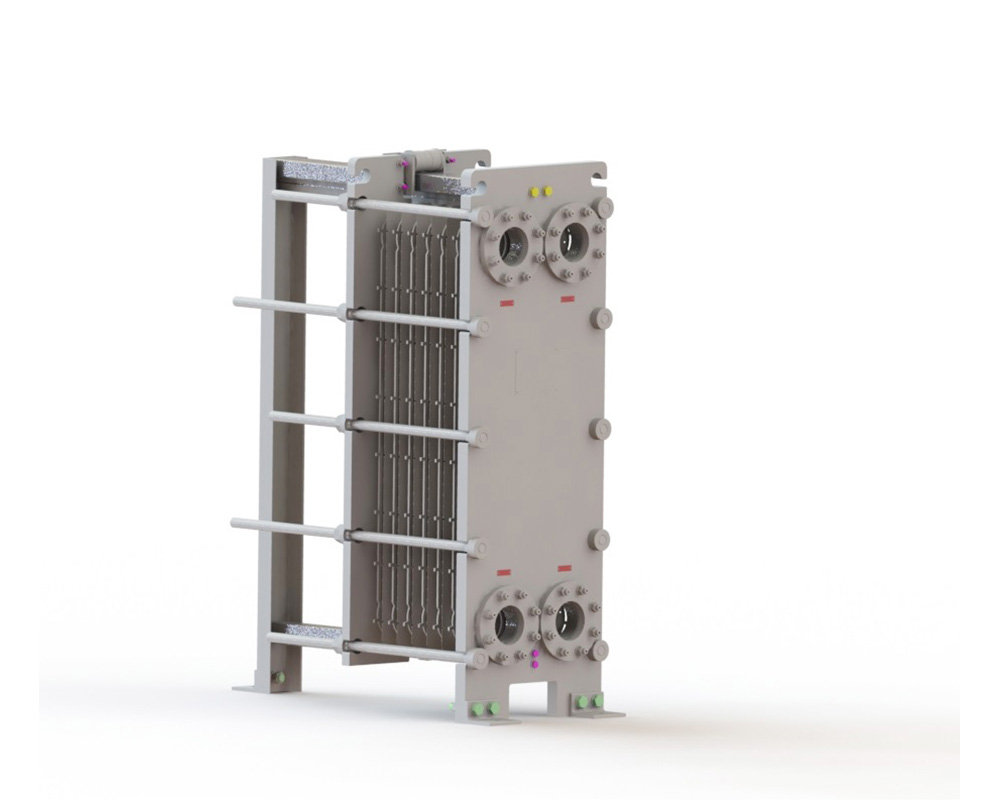

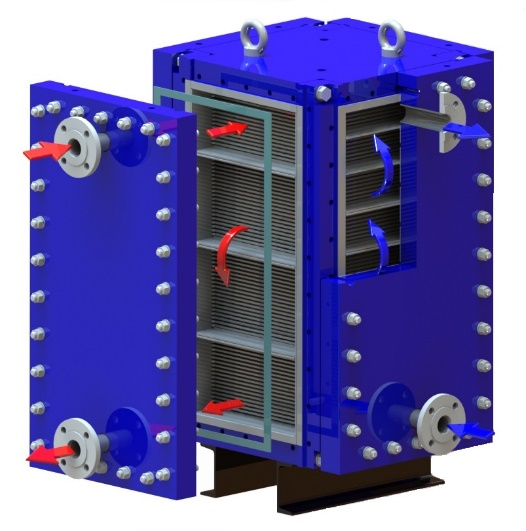

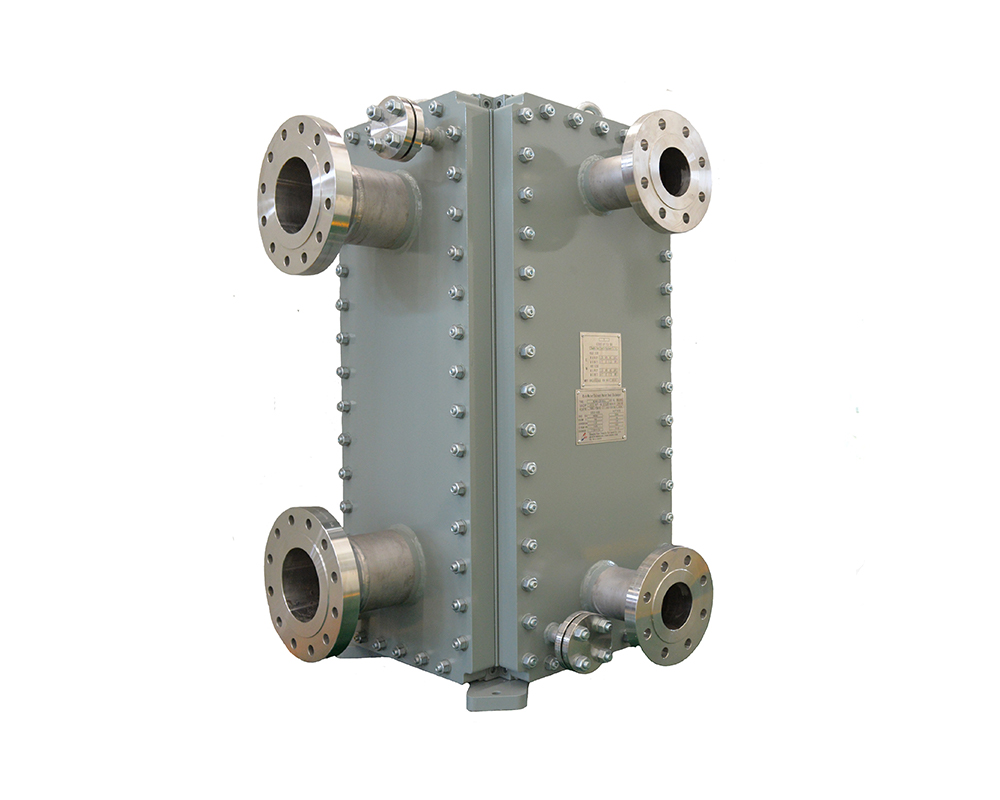

HT-Bloc plate heat exchanger is made up of plate pack and frame. The plate pack is certain number of plates welded together to form channels, then it is installed into a frame, which is formed by four corner girders, top and bottom plates and four side panels. The frame is bolted connected and can be easily disassembled for service and cleaning. There are three different plate patterns, corrugated, studded, and dimpled pattern, to meet different process requirements.

Why All Welded Bloc Plate Heat Exchanger?

1.Corrugated plate type. High heat transfer efficiency & good pressure-bearing,suitable for clean medium at both sides.

2.Cross flow for one pass HE, countercurrent flow for multiple pass HE to guarantee heat transfer.)

3.Plate pack is fully welded without gaskets.

4.Suitable for high temp., high pressure and corrosive process.

5.Flexible flow pass design

6.Different flow pass number at hot and cold side can ensure high heat transfer efficiency at both sides. Pass arrangement can be easily adjusted according to new process requirement.

7.Compact structure and small footprint

8.Frame can be disassembled to facilitate repair & cleaning.

Applications

☵ Refinery

Pre-heating of crude oil

Condensation of gasoline, kerosene, diesel, etc.

☵ Natural gas

Gas sweetening, decarburization ——lean/rich solvent service

Gas dehydration —— heat recovery in TEG systems

☵ Refined oil

Crude oil sweetening —— edible oil heat exchanger

☵ Coke over plants

Ammonia liquor scrubber cooling

Benzoilzed oil heating, cooling

☵ Refine sugar

mixed juice, fumigated juice heating

Pressure mooring juice heating

☵ Pulp and paper

Heat recovery of boil and fumigation

Heat recovery of bleaching process

Washing liquid heating

☵ Fuel ethanol

Lees liquid to fermented liquid heat exchange

Pre-heating of ethanol solution

☵ Chemicals, Metallurgy, Fertilizer production, Chemical fiber, Water treatment plant, etc.

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

Fast and good quotations, informed advisers to help you choose the correct product that suits all your needs, a short production time, responsible quality control and different services for paying and shipping affairs for Factory directly supply Thermal Transfer Heat Exchanger - All Welded Bloc Plate Heat Exchanger – Shphe , The product will supply to all over the world, such as: British , Irish , Austria , We set be a creditable practitioner to achieve the continuous development and innovation as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.