Chinese wholesale Cooling Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in sugar plant – Shphe

Chinese wholesale Cooling Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in sugar plant – Shphe Detail:

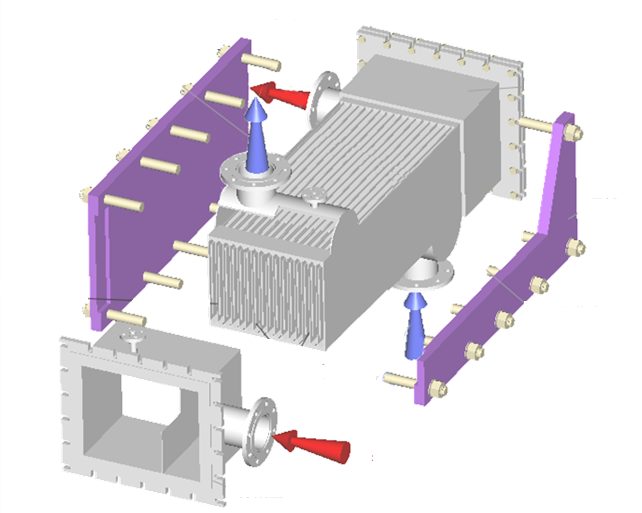

How it works

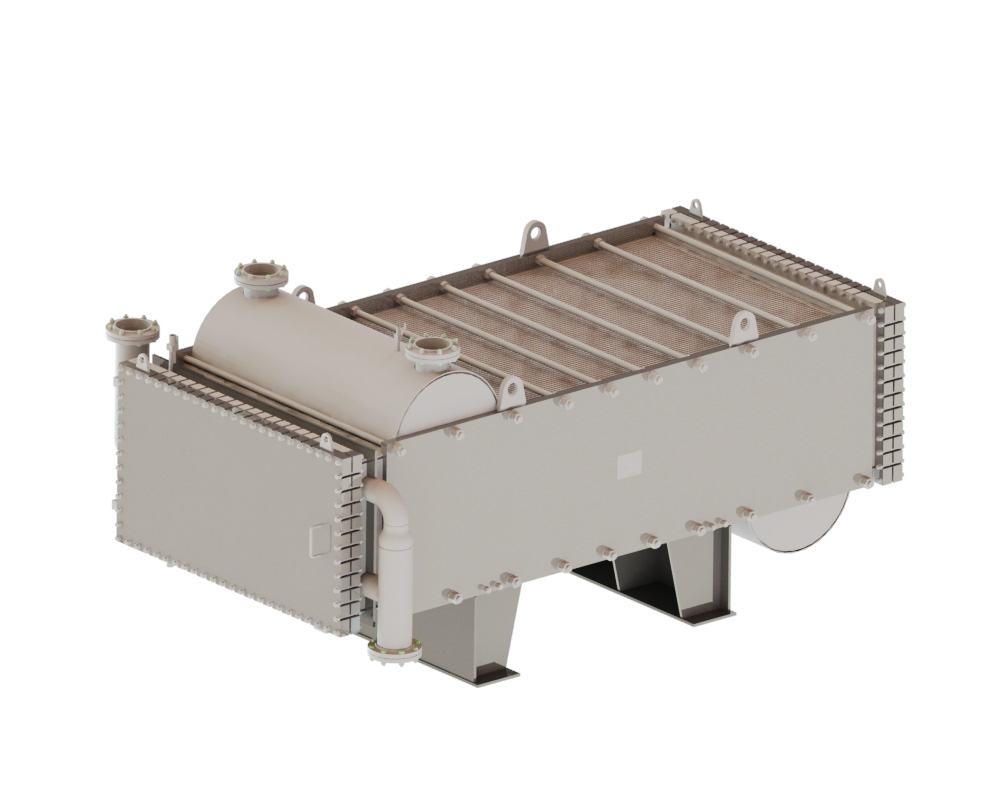

Wide gap welded plate heat exchanger is specially applied in thermal process of medium which contain much solid particles and fiber suspensions or heat-up and cool down of viscous fluid in sugar plant , paper mill, metallurgy, alcohol and chemical industry

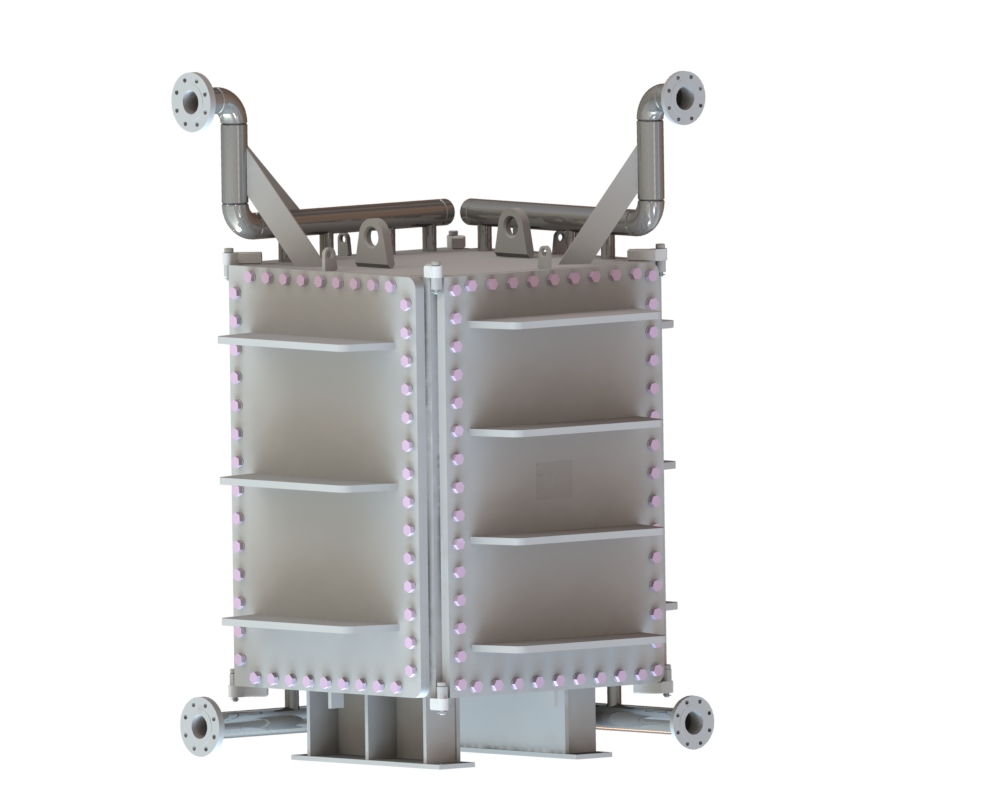

Two plate patterns available for wide-gap welded plate heat exchanger, ie. dimple pattern and studded flat pattern. Flow channel is formed between plates which are welded together. Thanks for the unique design of wide gap heat exchanger, it keeps the advantage of high heat transfer efficiency and low pressure drop over other type of exchangers at the same process.

Moreover, Special design of the heat exchange plate ensures smooth flow of the fluid in the wide gap path. No “dead area”, no deposition or blockage of the solid particles or suspensions, it keeps the fluid go through the exchanger smoothly without clogging.

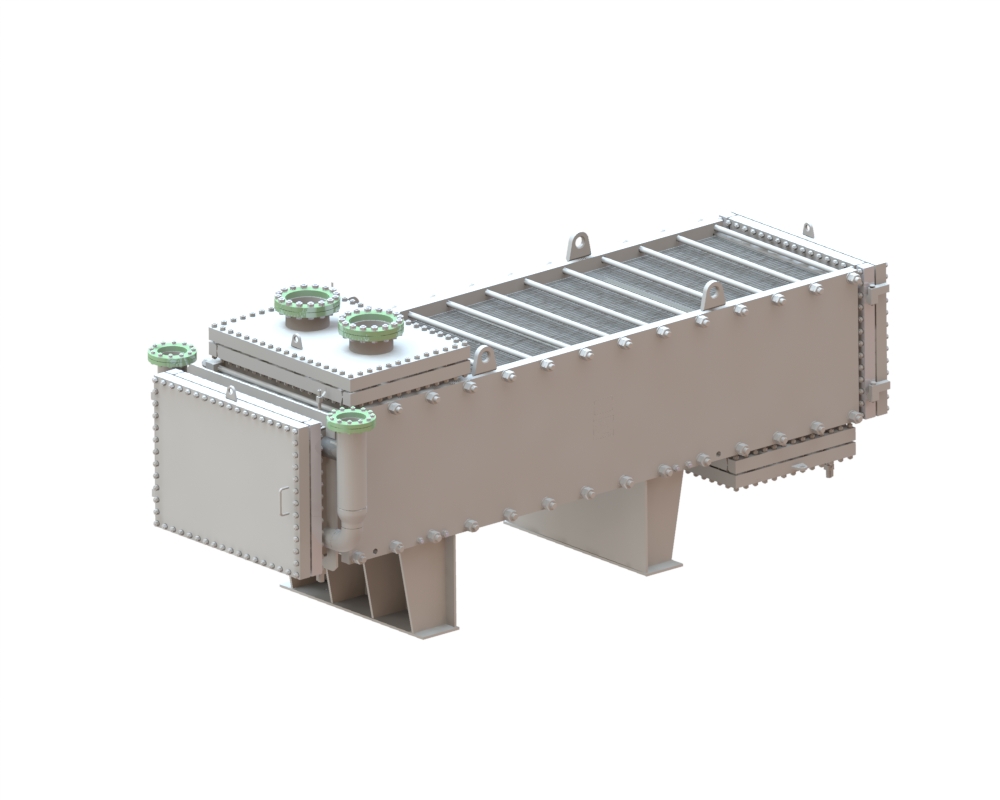

Application

☆ The wide gap welded plate heat exchangers are used for the slurry heating or cooling which contain solids or fibers, eg.

☆ sugar plant, pulp & paper, metallurgy, ethanol, oil & gas, chemical industries.

Such as:

● Slurry cooler,Quench water cooler,Oil cooler

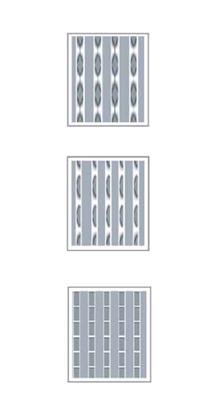

Structure of plate pack

☆ The channel at one side is formed by spot-welded contact points that between dimple-corrugated plates. Cleaner medium runs in this channel. The channel at the other side is wide gap channel formed between dimple-corrugated plates with no contact points, and high viscous medium or medium containing coarse particles runs in this channel.

☆ The channel at one side is formed by spot-welded contact points that are connected between dimple-corrugated plate and flat plate. Cleaner medium runs in this channel. The channel at the other side is formed between dimple-corrugated plate and flat plate with wide gap and no contact point. The medium containing coarse particles or high viscous medium runs in this channel.

☆ The channel at one side is formed between flat plate and flat plate that welded together with studs. The channel at the other side is formed between flat plates with wide gap, no contact point. Both channels are suitable for high viscous medium or medium containing coarse particles and fiber.

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

We often persist with the theory Quality To start with, Prestige Supreme. We are fully committed to delivering our clientele with competitively priced good quality items, prompt delivery and experienced support for Chinese wholesale Cooling Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in sugar plant – Shphe , The product will supply to all over the world, such as: Russia , Macedonia , Brasilia , Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.