8 Year Exporter Stainless Steel Heat Exchanger Coil - Plate type Air preheater for Reformer Furnace – Shphe

8 Year Exporter Stainless Steel Heat Exchanger Coil - Plate type Air preheater for Reformer Furnace – Shphe Detail:

How it works

☆ Plate type air preheater is a kind of energy saving and environmental protection equipment.

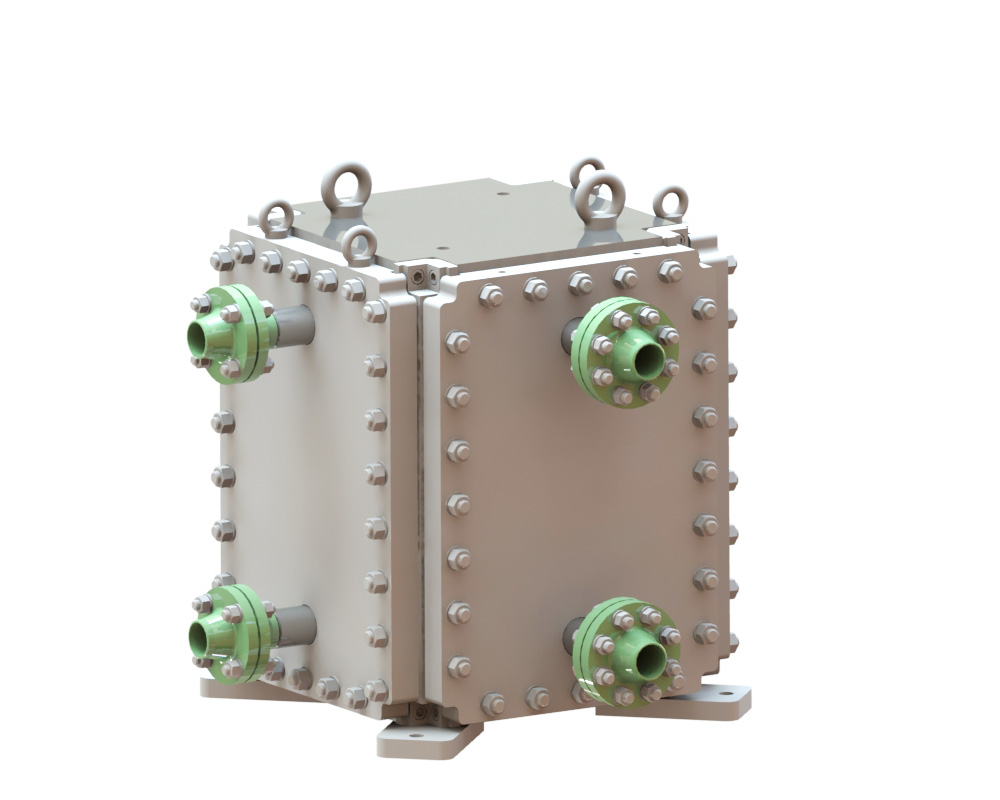

☆ The main heat transfer element, ie. flat plate or corrugated plate are welded together or mechanically fixed to form plate pack. The modular design of the product makes the structure flexible. The unique AIR FILMTM technology solved the dew point corrosion. Air preheater is widely used in oil refinery, chemical, steel mill, power plant, etc.

Application

☆ Reformer furnace for hydrogen, delayed coking furnace, cracking furnace

☆ High temperature smelter

☆ Steel blast furnace

☆ Garbage incinerator

☆ Gas heating and cooling in chemical plant

☆ Coating machine heating, recovery of tail gas waste heat

☆ Waste heat recovery in glass/ceramic industry

☆ Tail gas treating unit of spray system

☆ Tail gas treating unit of non-ferrous metallurgy industry

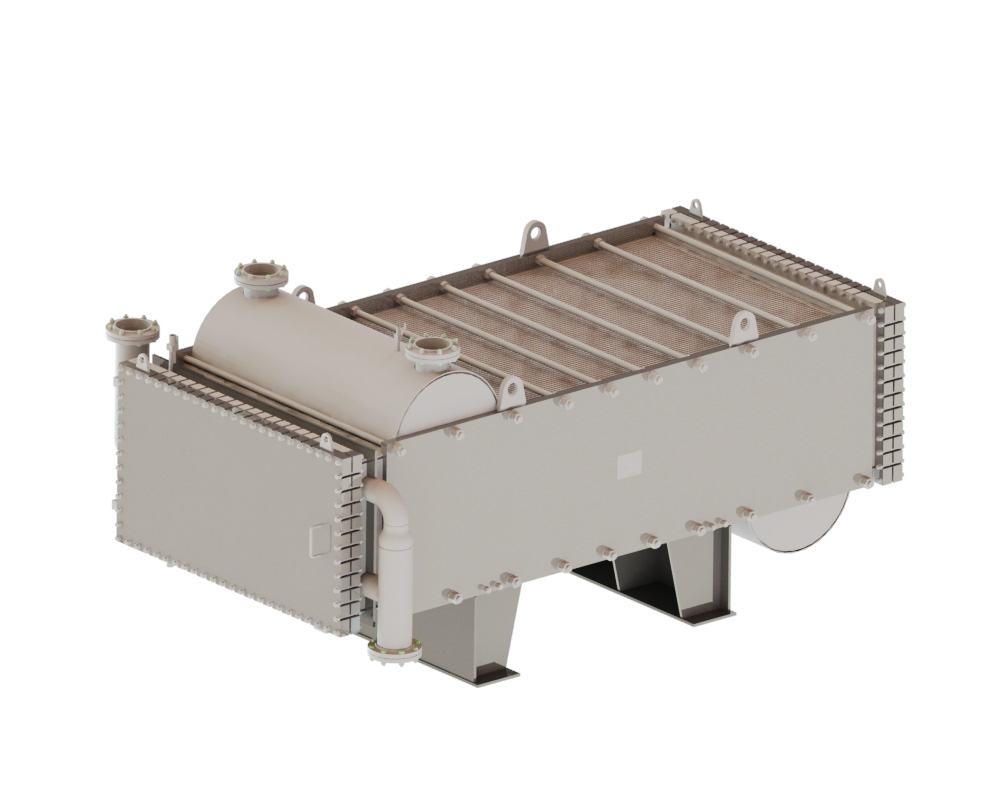

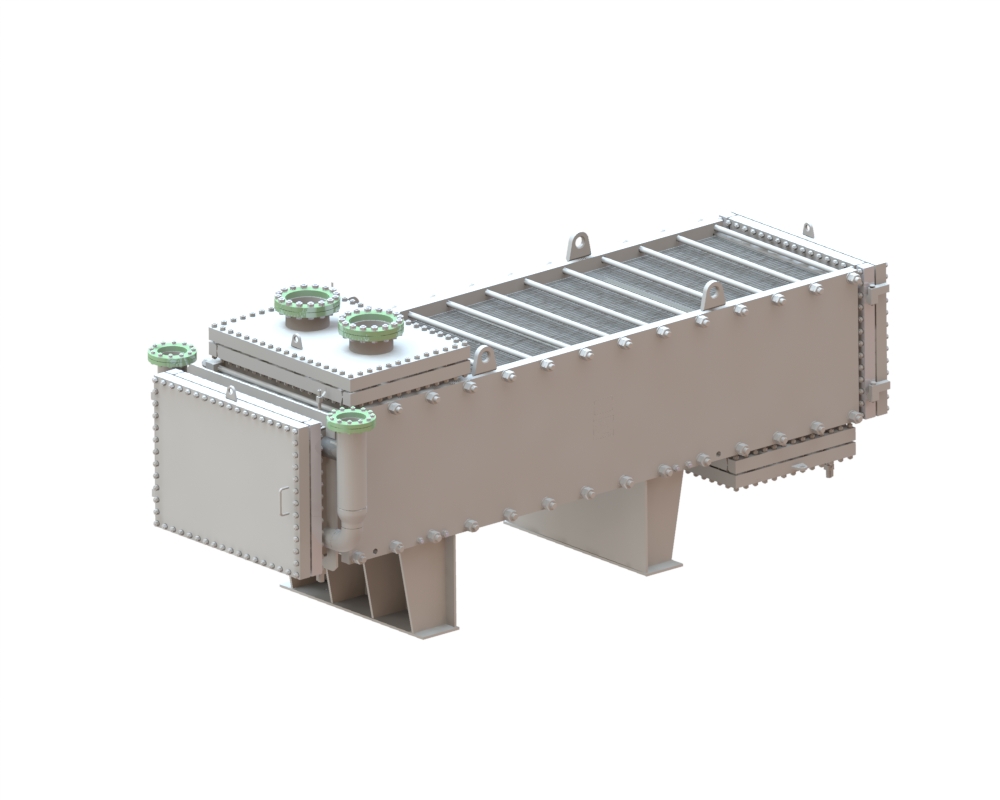

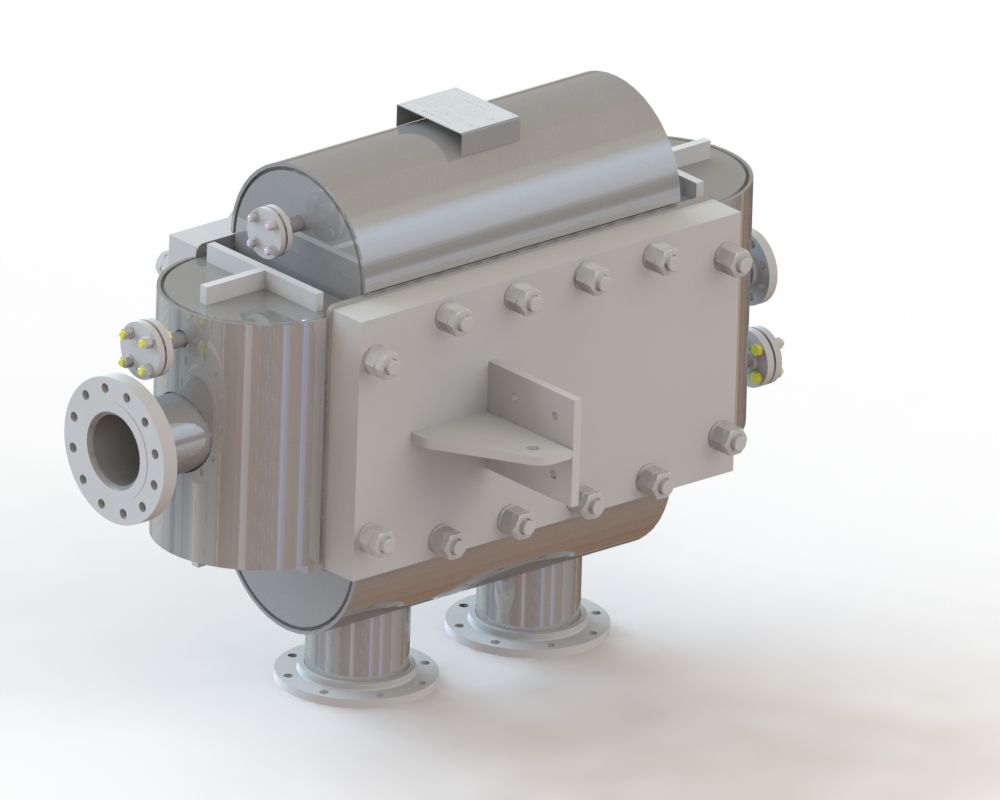

Product detail pictures:

Related Product Guide:

Cooperation

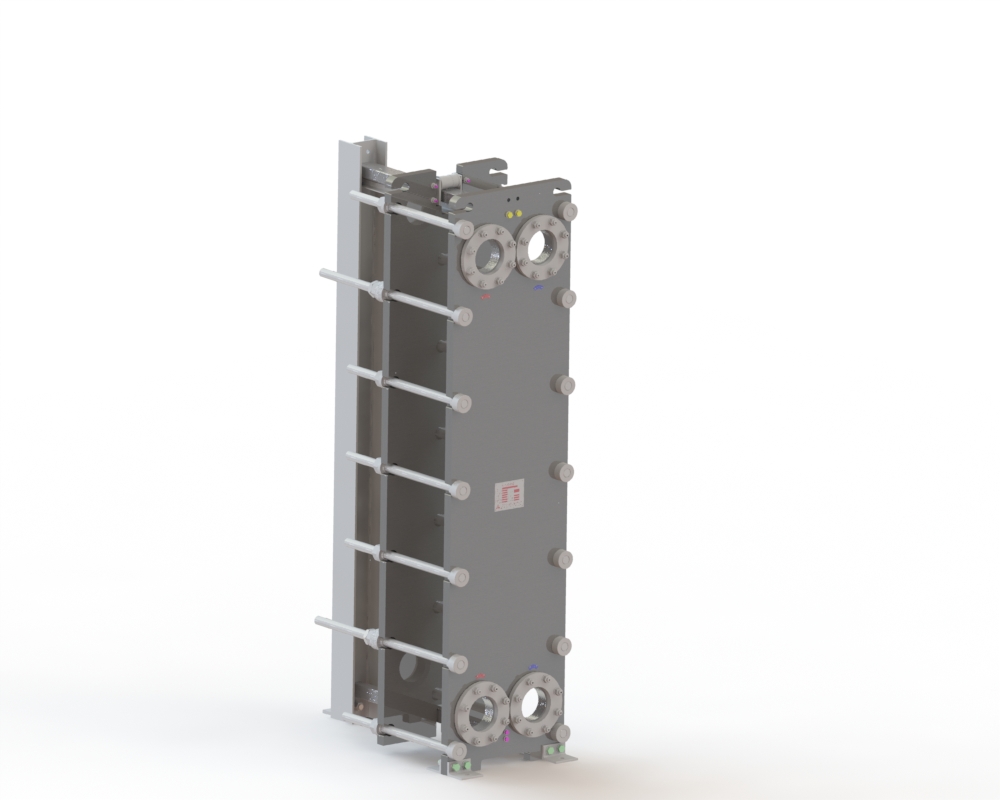

Plate Heat Exchanger made with DUPLATE™ plate

To create more value for customers is our business philosophy; customer growing is our working chase for 8 Year Exporter Stainless Steel Heat Exchanger Coil - Plate type Air preheater for Reformer Furnace – Shphe , The product will supply to all over the world, such as: Philippines , Manila , Eindhoven , Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!