8 Year Exporter Heat Exchanger Cost - Wide Gap Welded Plate Heat Exchanger used in sugar plant – Shphe

8 Year Exporter Heat Exchanger Cost - Wide Gap Welded Plate Heat Exchanger used in sugar plant – Shphe Detail:

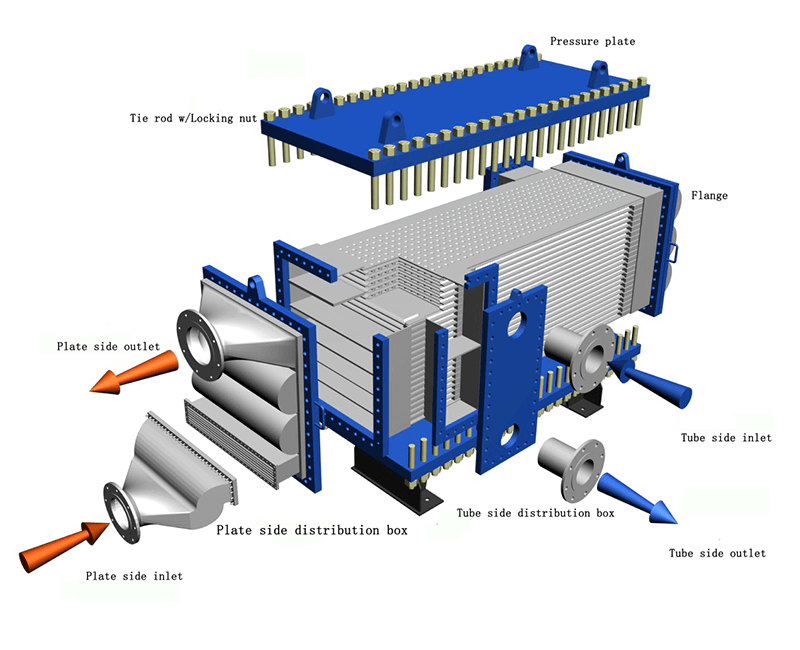

How it works

☆ Two plate patterns available for wide-gap welded plate heat exchanger, ie.

☆ dimple pattern and studded flat pattern.

☆ Flow channel is formed between plates which are welded together.

☆ Thanks for the unique design of wide gap heat exchanger, it keeps the advantage of high heat transfer efficiency and low pressure drop over other type of exchangers at the same process.

☆ Moreover, Special design of the heat exchange plate ensures smooth flow of the fluid in the wide gap path.

☆ No “dead area”, no deposition or blockage of the solid particles or suspensions, it keeps the fluid go through the exchanger smoothly without clogging.

Application

☆ The wide gap welded plate heat exchangers are used for the slurry heating or cooling which contain solids or fibers, eg.

☆ sugar plant, pulp & paper, metallurgy, ethanol, oil & gas, chemical industries.

Such as:

● Slurry cooler,Quench water cooler,Oil cooler

Structure of plate pack

☆ The channel at one side is formed by spot-welded contact points that between dimple-corrugated plates. Cleaner medium runs in this channel. The channel at the other side is wide gap channel formed between dimple-corrugated plates with no contact points, and high viscous medium or medium containing coarse particles runs in this channel.

☆ The channel at one side is formed by spot-welded contact points that are connected between dimple-corrugated plate and flat plate. Cleaner medium runs in this channel. The channel at the other side is formed between dimple-corrugated plate and flat plate with wide gap and no contact point. The medium containing coarse particles or high viscous medium runs in this channel.

☆ The channel at one side is formed between flat plate and flat plate that welded together with studs. The channel at the other side is formed between flat plates with wide gap, no contact point. Both channels are suitable for high viscous medium or medium containing coarse particles and fiber.

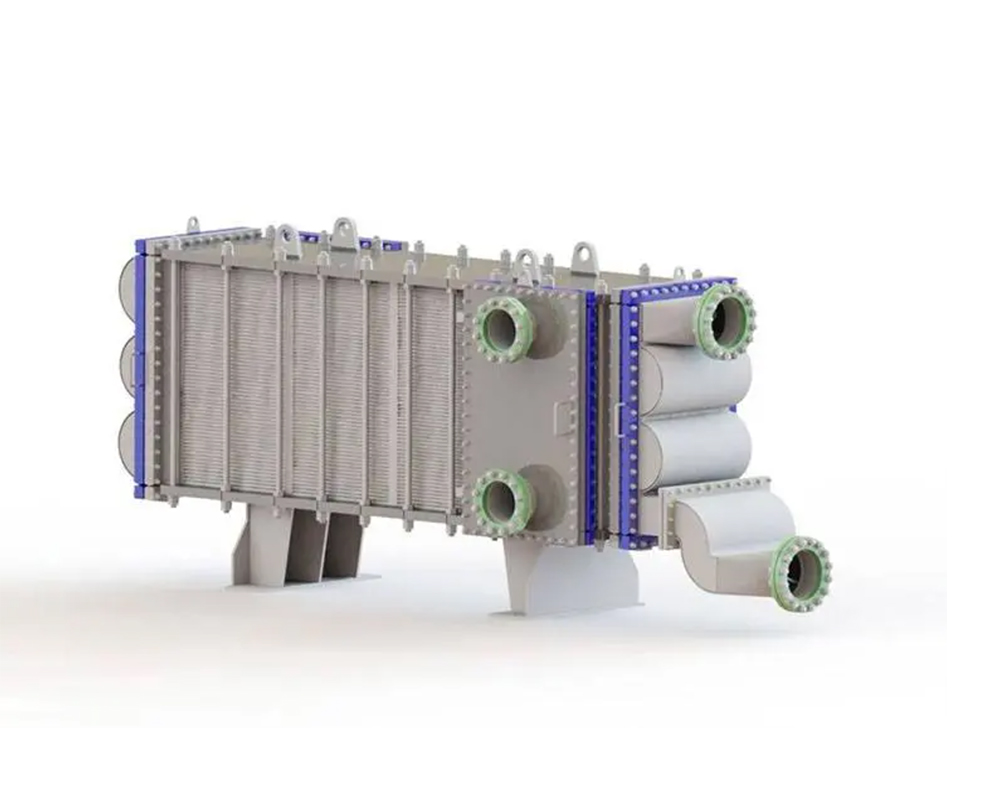

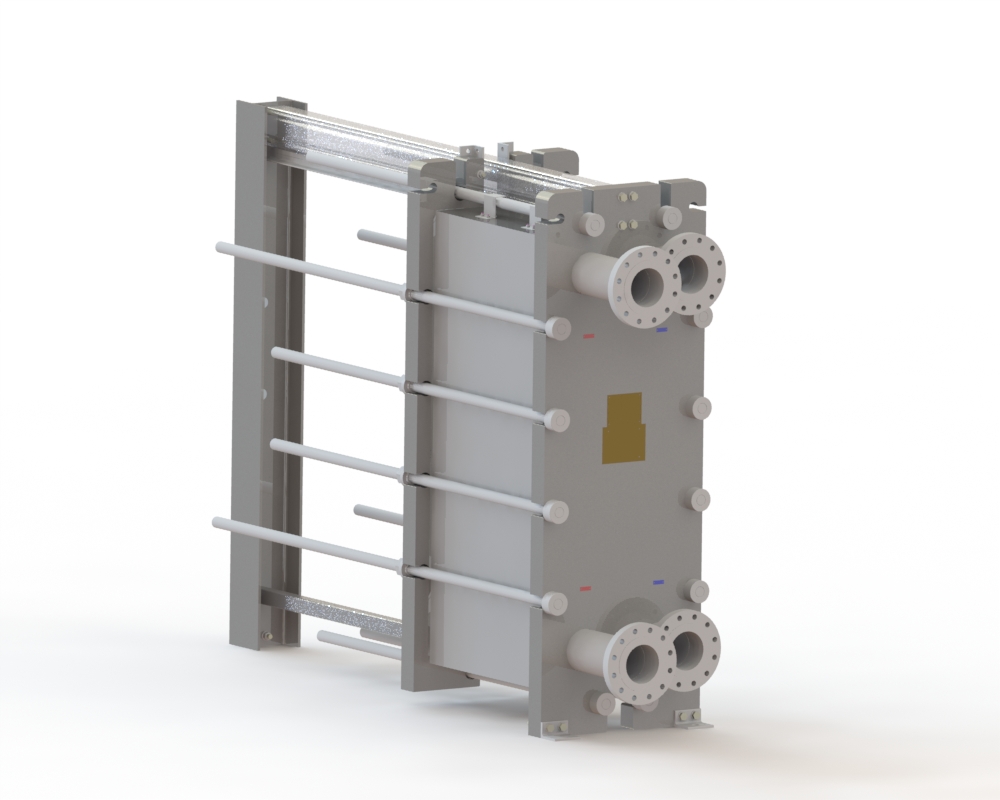

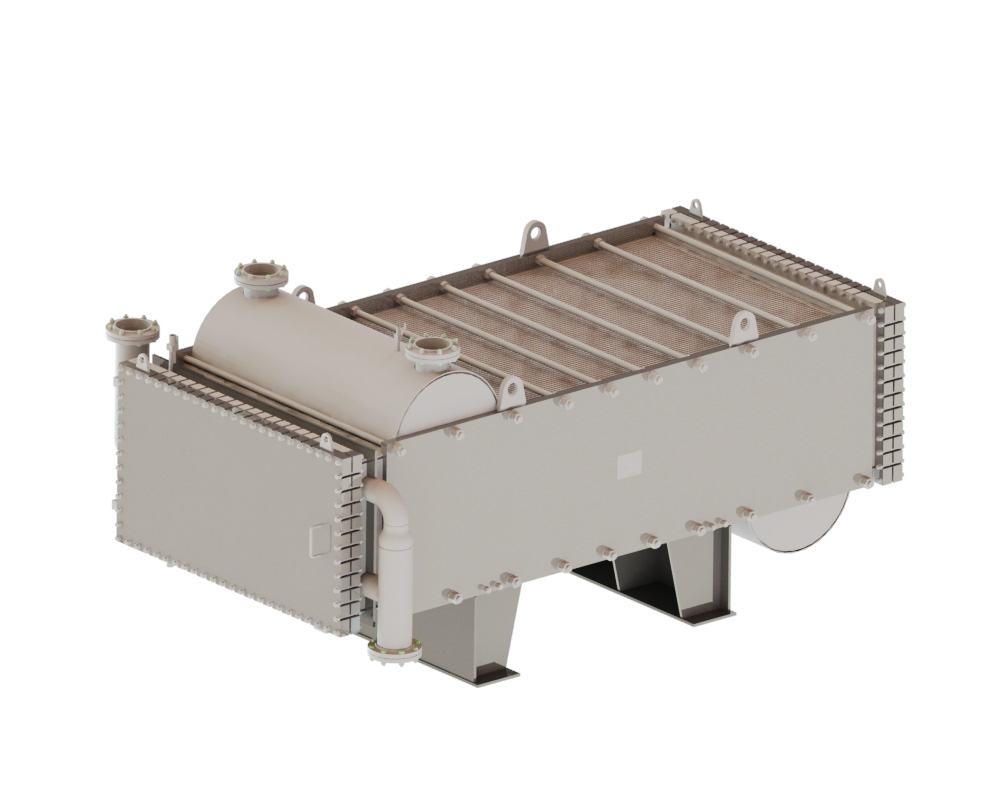

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

Our pursuit and firm aim should be to Always fulfill our buyer requirements. We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for 8 Year Exporter Heat Exchanger Cost - Wide Gap Welded Plate Heat Exchanger used in sugar plant – Shphe , The product will supply to all over the world, such as: Liberia , Iran , Grenada , We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.