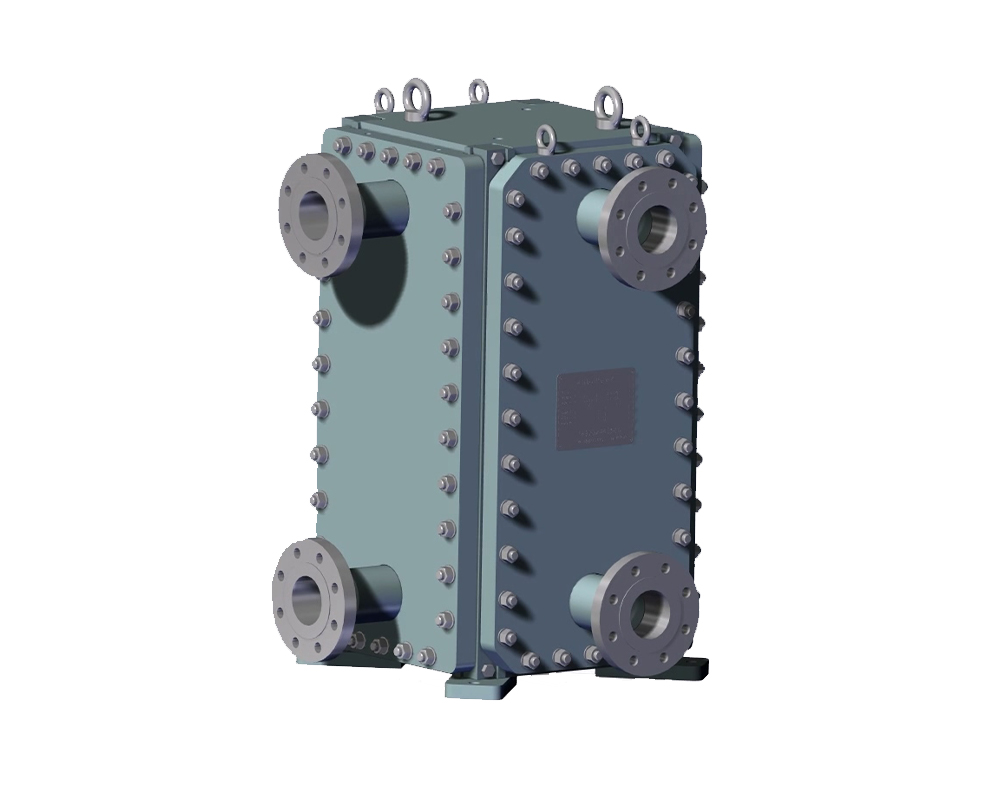

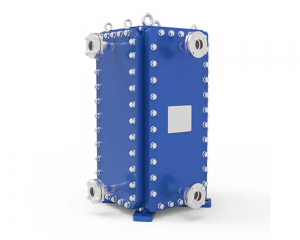

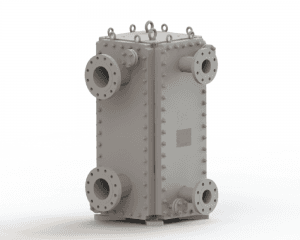

HT-Bloc Welded Plate Heat Exchanger

What is HT-Bloc welded heat exchanger?

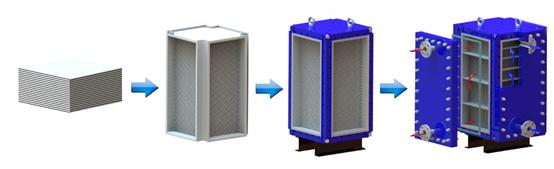

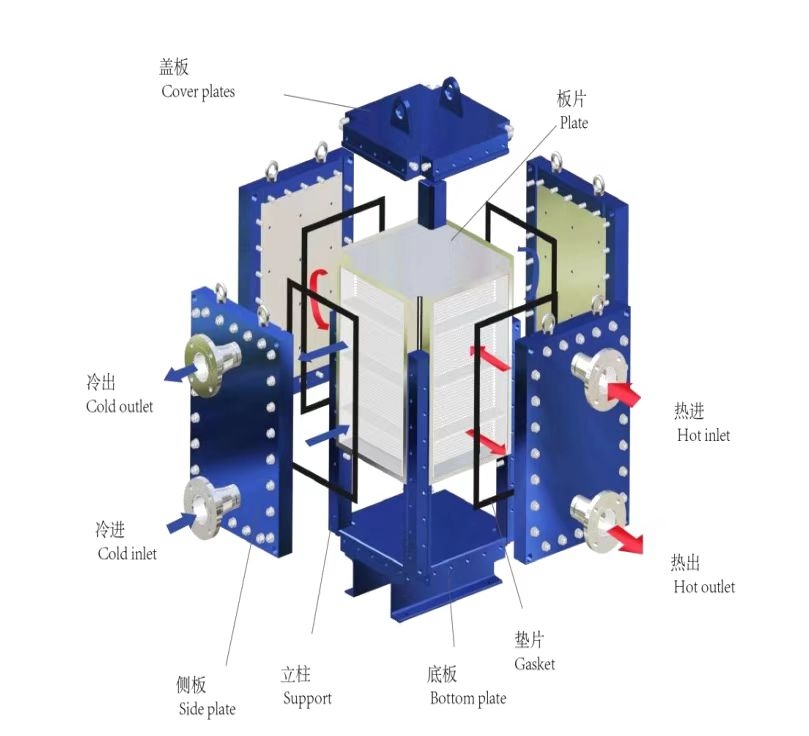

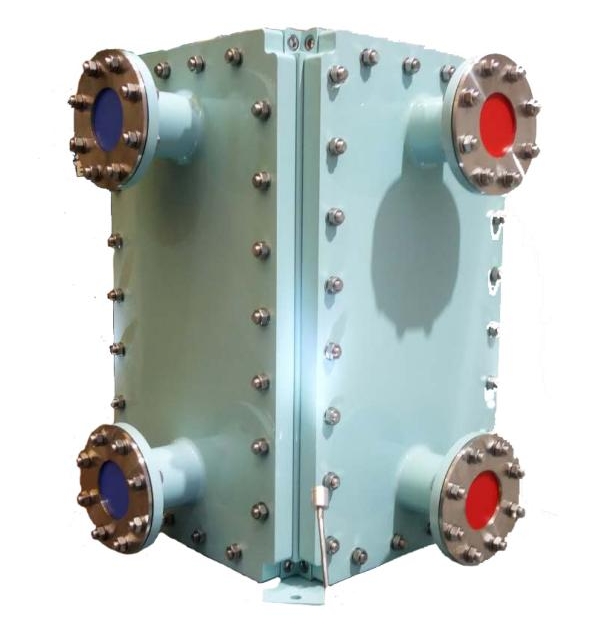

HT-Bloc welded heat exchanger is made up of plate pack and frame. The plate pack is formed by welding a certain number of plates, then it is installed into a frame, which is configured by four corner girders, top and bottom plates and four side covers.

Application

As a high-performance fully welded heat exchanger for process industries, HT-Bloc welded heat exchanger is widely used in oil refinery, chemical, metallurgy, power, pulp & paper, coke and sugar industry.

Advantages

Why isHT-Bloc welded heat exchanger suitable for various industries?

The reason lies in a range of advantages of HT-Bloc welded heat exchanger:

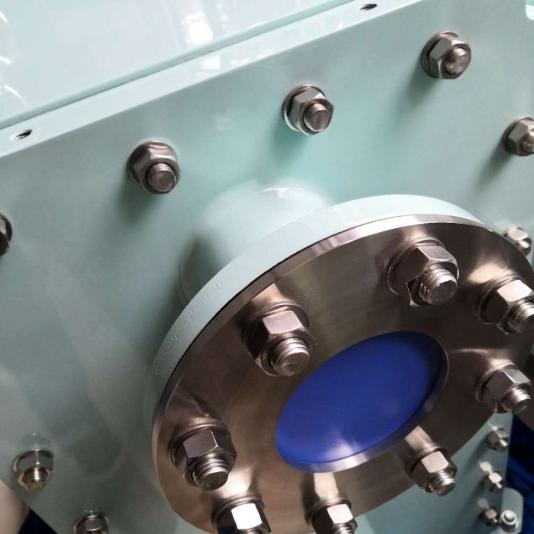

First of all, the plate pack is fully welded without gasket, which allows it to be used at process with high-pressure and high-temperature.

Secondly, the frame is bolted connected and can be easily disassembled for inspection, service and cleaning.

Thirdly, the corrugated plates promote high turbulence which provides high heat transfer efficiency and help minimize fouling.

Last but not least, with exceedingly compact structure and small footprint, it can significantly reduce the installation cost.

With a focus on performance, compactness, and serviceability, the HT-Bloc welded heat exchangers are always designed for providing the most efficient, compact and cleanable heat exchange solution.