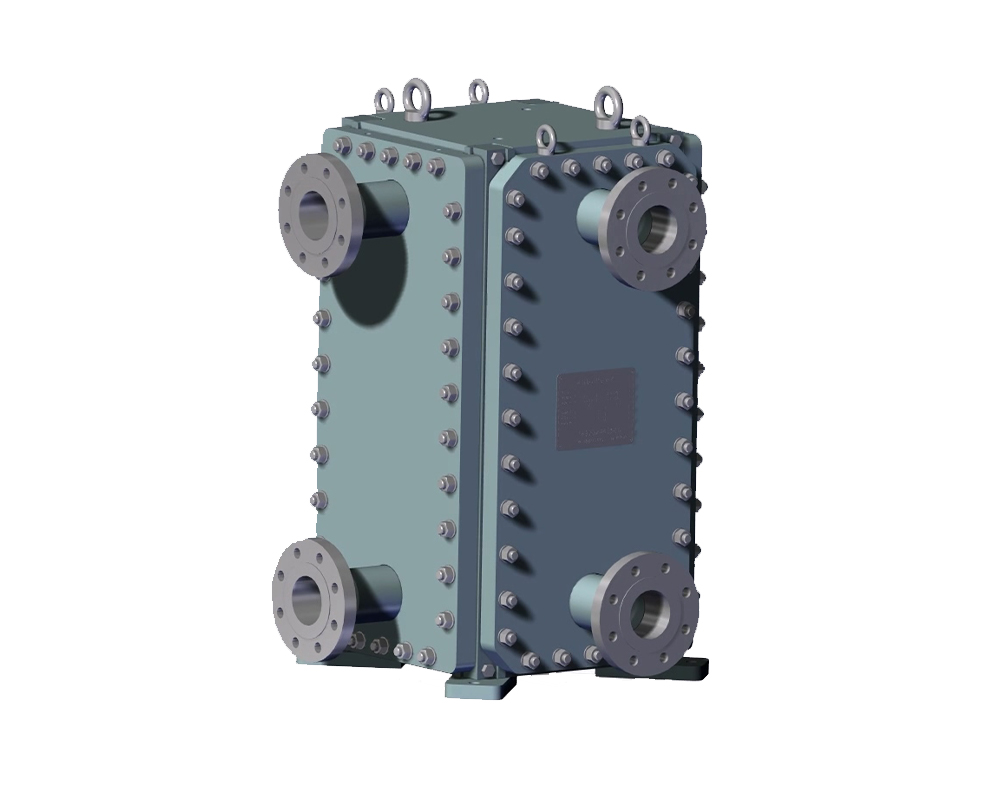

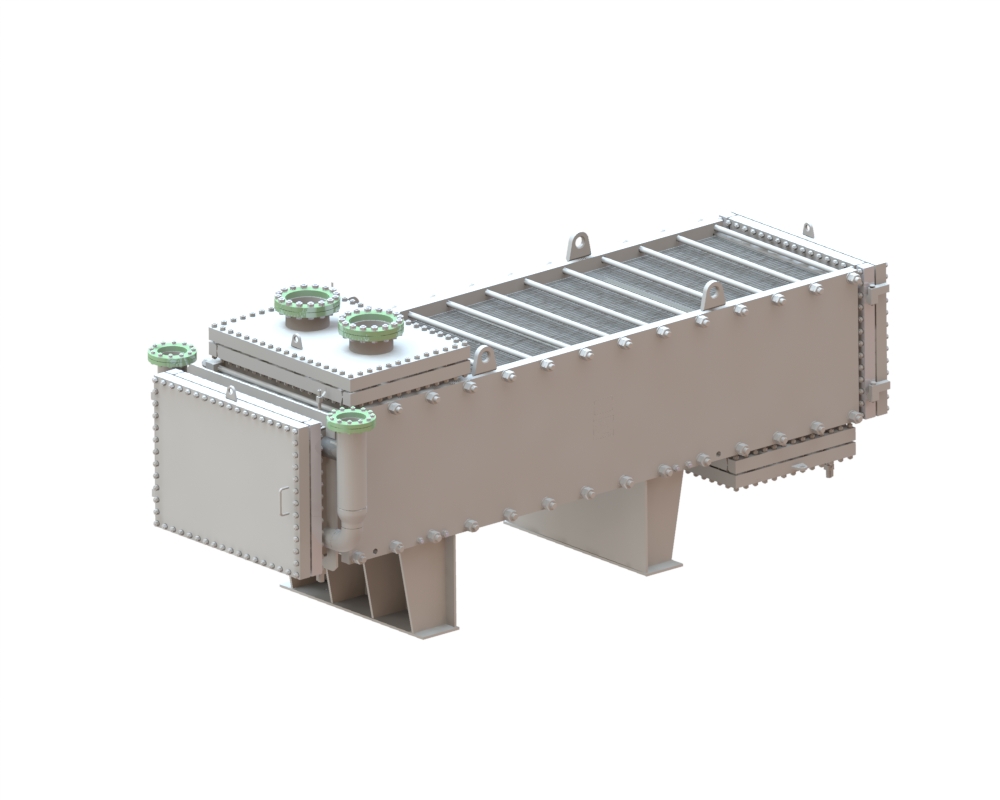

Renewable Design for Counter Flow Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in ethanol industry – Shphe

Renewable Design for Counter Flow Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in ethanol industry – Shphe Detail:

How it works

Application

The wide gap welded plate heat exchangers are used for the slurry heating or cooling which contain solids or fibers, eg. Sugar plant, pulp & paper, metallurgy, ethanol, oil & gas, chemical industries.

Such as:

● Slurry cooler

● Quench water cooler

● Oil cooler

Structure of plate pack

☆ The channel at one side is formed by spot-welded contact points that between dimple-corrugated plates. Cleaner medium runs in this channel. The channel at the other side is wide gap channel formed between dimple-corrugated plates with no contact points, and high viscous medium or medium containing coarse particles runs in this channel.

☆ The channel at one side is formed by spot-welded contact points that are connected between dimple-corrugated plate and flat plate. Cleaner medium runs in this channel. The channel at the other side is formed between dimple-corrugated plate and flat plate with wide gap and no contact point. The medium containing coarse particles or high viscous medium runs in this channel.

☆ The channel at one side is formed between flat plate and flat plate that welded together with studs. The channel at the other side is formed between flat plates with wide gap, no contact point. Both channels are suitable for high viscous medium or medium containing coarse particles and fiber.

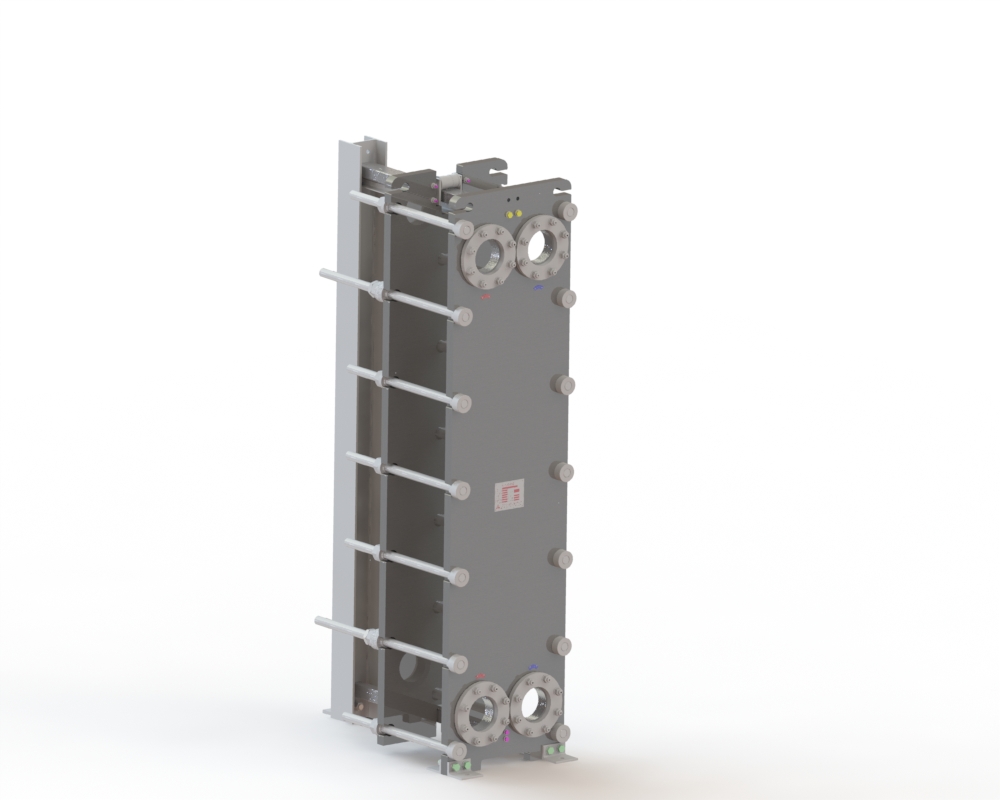

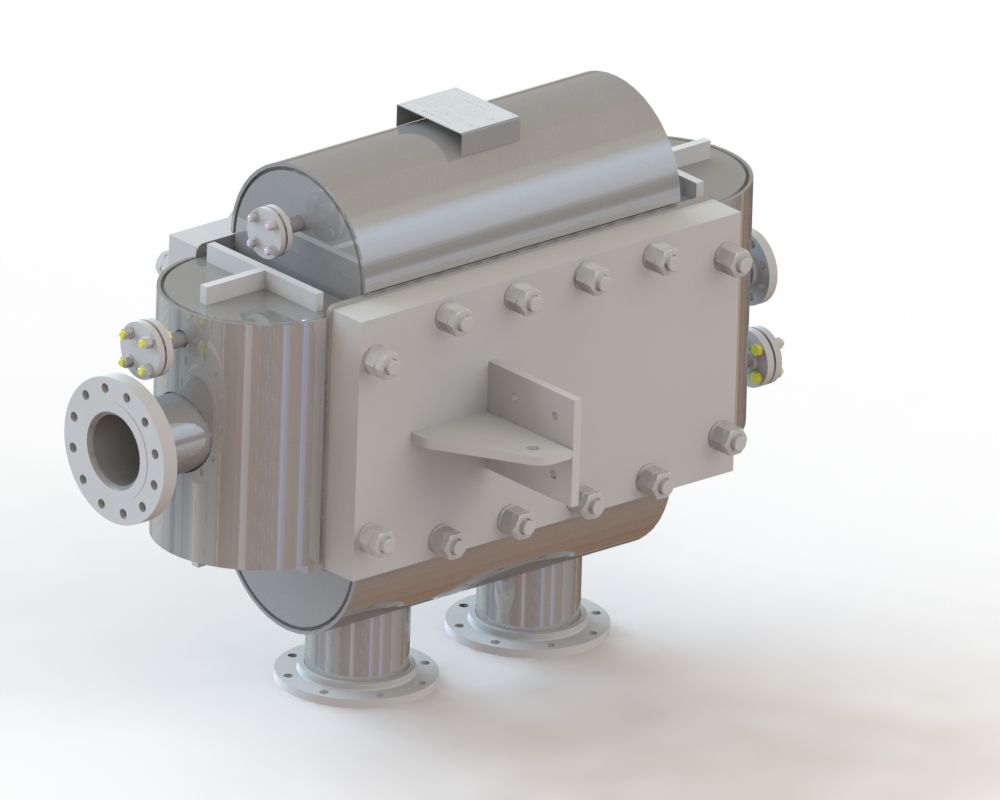

Product detail pictures:

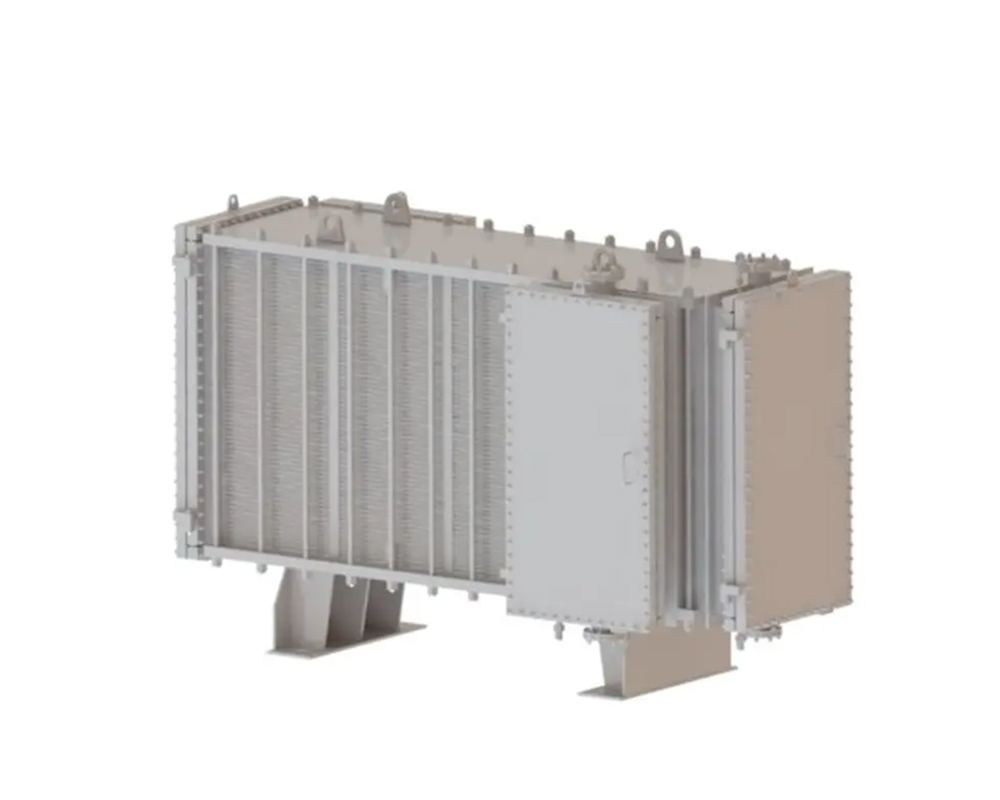

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for Renewable Design for Counter Flow Heat Exchanger - Wide Gap Welded Plate Heat Exchanger used in ethanol industry – Shphe , The product will supply to all over the world, such as: Latvia , Ukraine , Costa Rica , Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!