OEM/ODM Factory Diesel Engine Heat Exchanger - Modular design Plate type Air preheater – Shphe

OEM/ODM Factory Diesel Engine Heat Exchanger - Modular design Plate type Air preheater – Shphe Detail:

How it works

☆ Plate type air preheater is a kind of energy saving and environmental protection equipment.

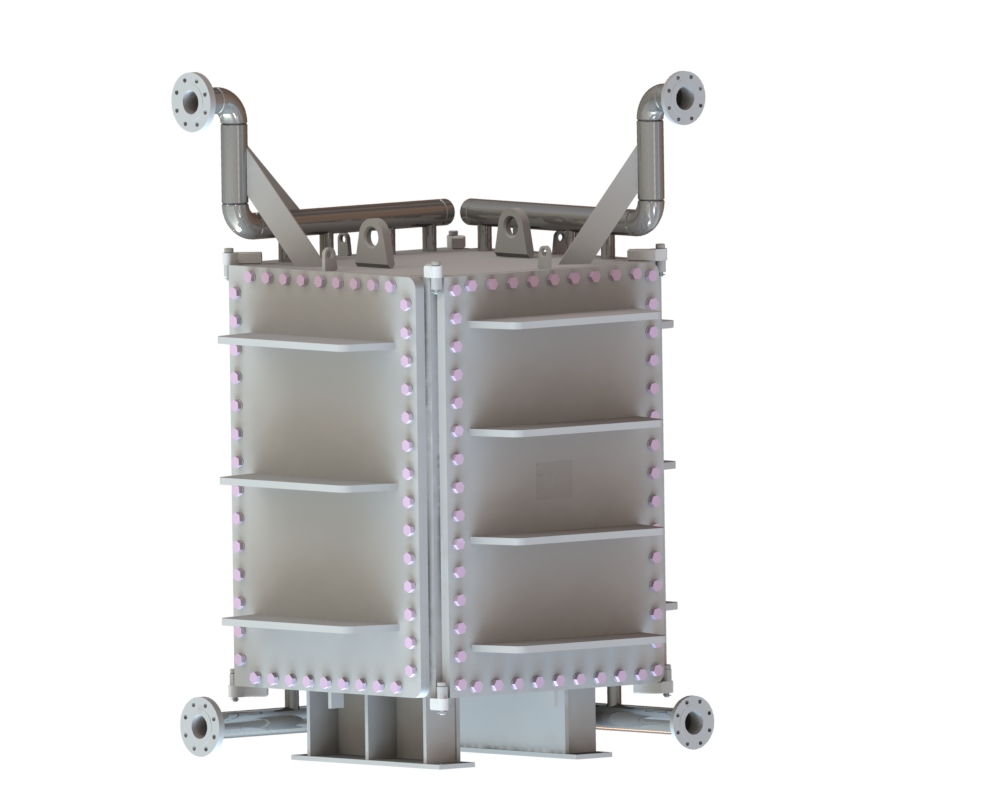

☆ The main heat transfer element, ie. flat plate or corrugated plate are welded together or mechanically fixed to form plate pack. The modular design of the product makes the structure flexible. The unique AIR FILMTM technology solved the dew point corrosion. Air preheater is widely used in oil refinery, chemical, steel mill, power plant, etc.

Application

☆ Reformer furnace for hydrogen, delayed coking furnace, cracking furnace

☆ High temperature smelter

☆ Steel blast furnace

☆ Garbage incinerator

☆ Gas heating and cooling in chemical plant

☆ Coating machine heating, recovery of tail gas waste heat

☆ Waste heat recovery in glass/ceramic industry

☆ Tail gas treating unit of spray system

☆ Tail gas treating unit of non-ferrous metallurgy industry

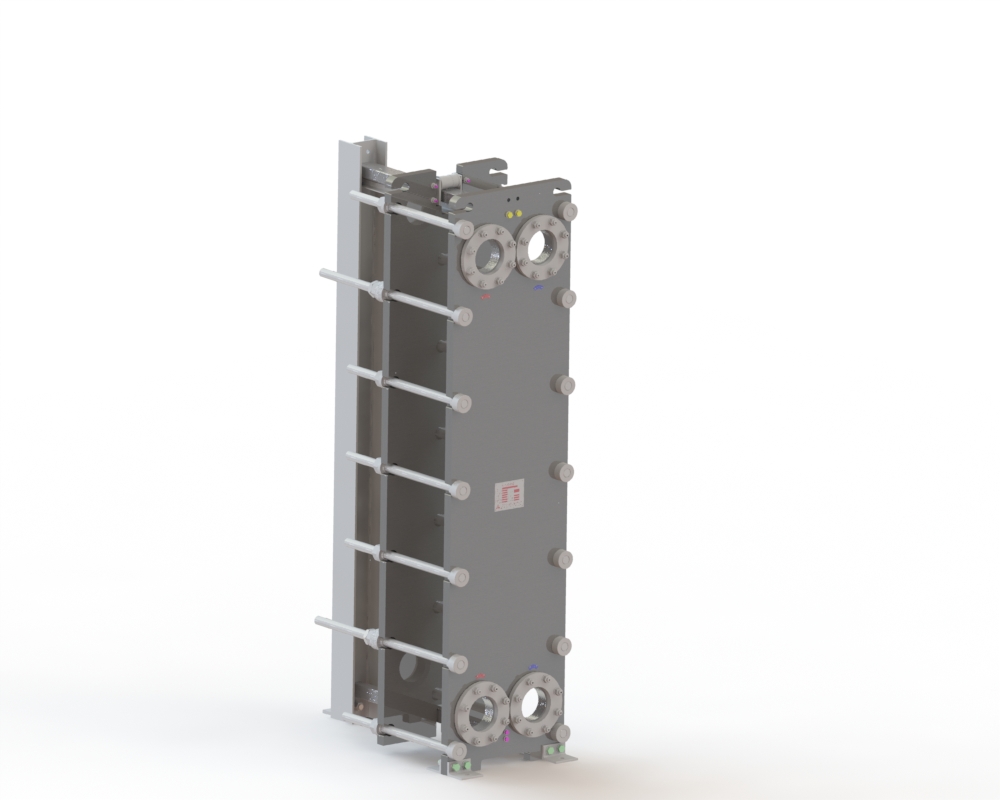

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

We persistently execute our spirit of Innovation bringing growth, Highly-quality making sure subsistence, Administration marketing reward, Credit history attracting clients for OEM/ODM Factory Diesel Engine Heat Exchanger - Modular design Plate type Air preheater – Shphe , The product will supply to all over the world, such as: Finland , Slovenia , Swiss , Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!