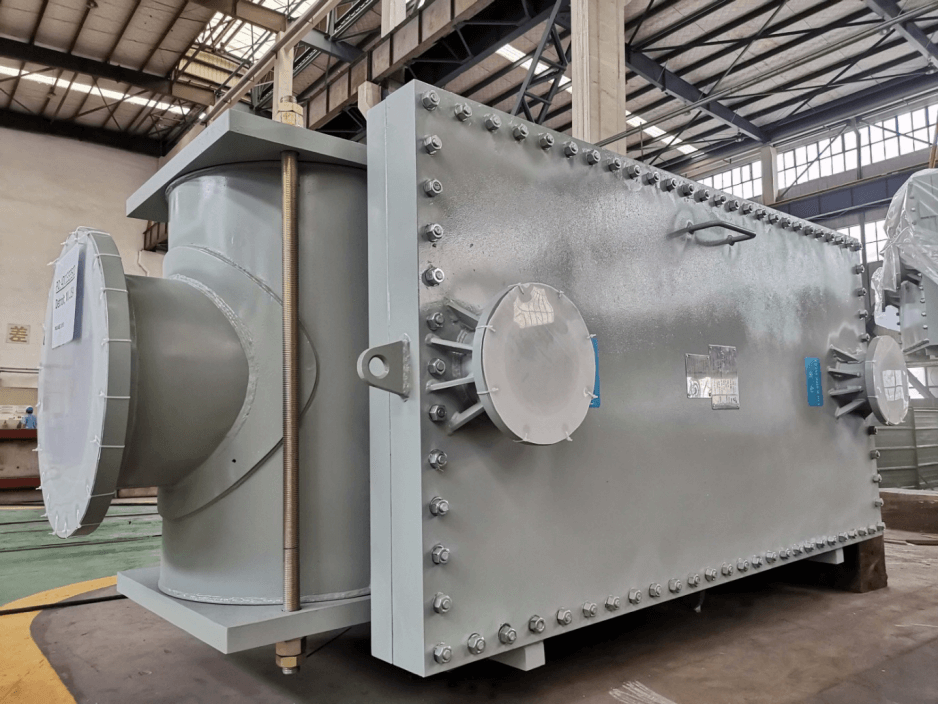

SHPHE overcame the difficulties during the epidemic, Various measures had finally ensured that the two TP welded plate heat exchangers exported to the United States successfully passed the third-party acceptance and were shipped on May 15.

The heat exchanger is welded by an advanced automatic welding machine. All the plate bundles are welded in the shell, and the shell can be opened for mechanical cleaning of the flow path. The special flow channel structure ensures that there will be no liquid leakage and leakage between the media. It not only has the advantages of efficient heat transfer and compact structure of plate heat exchanger, but also has the characteristics of high pressure and high temperature resistance of shell and tube heat exchanger. It is a kind of special and ideal equipment for heat exchangers.

The TP welded plate heat exchanger produced by SHPHE has been widely used in petroleum, chemical, electric power, metallurgy, HVAC, food and medicine industries.

The design and manufacture of the project’s products are strictly in accordance with the latest ASME standard requirements. Through the successful completion of the product certification project (ASME U stamp and NB stamp), our company is further familiar with the requirements of ASME code design and manufacturing, and evaluates and verifies the compliance, suitability and effectiveness of SHPHE ASME quality control system operation. Continuously understand and apply international common standards to design and manufacture products that meet the requirements of the international market, and constantly improve quality control and management to meet and exceed user expectations.

Post time: May-20-2020