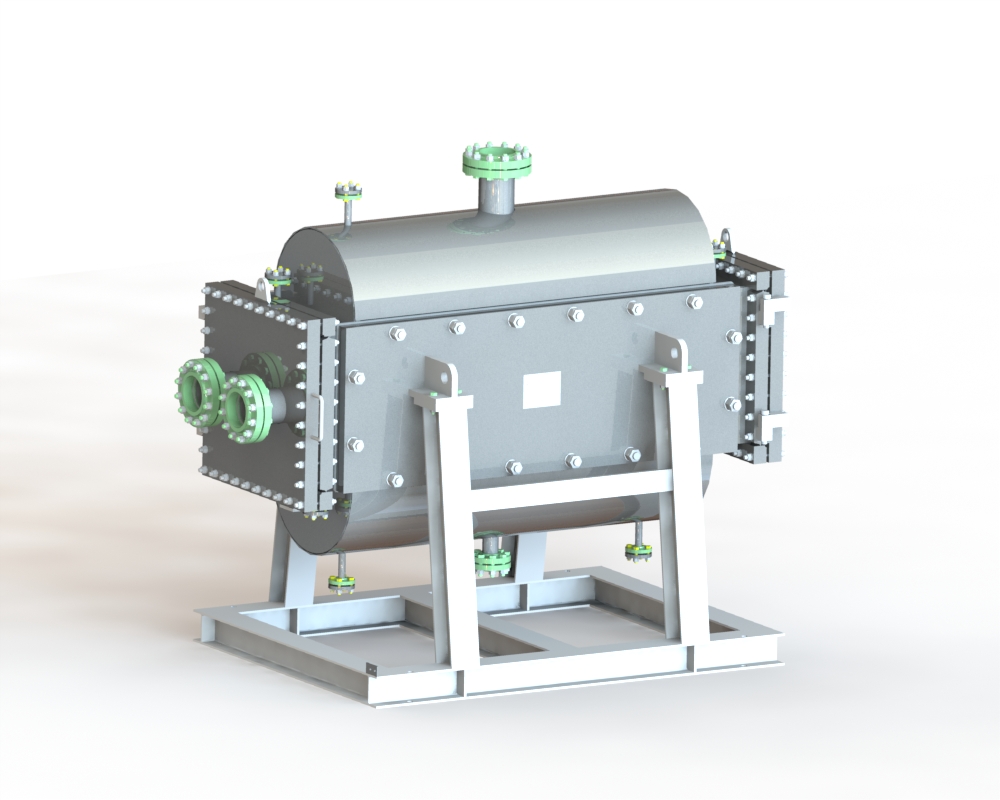

Massive Selection for Gas Heat Exchanger Design - Plate type Air preheater for Reformer Furnace – Shphe

Massive Selection for Gas Heat Exchanger Design - Plate type Air preheater for Reformer Furnace – Shphe Detail:

How it works

☆ Plate type air preheater is a kind of energy saving and environmental protection equipment.

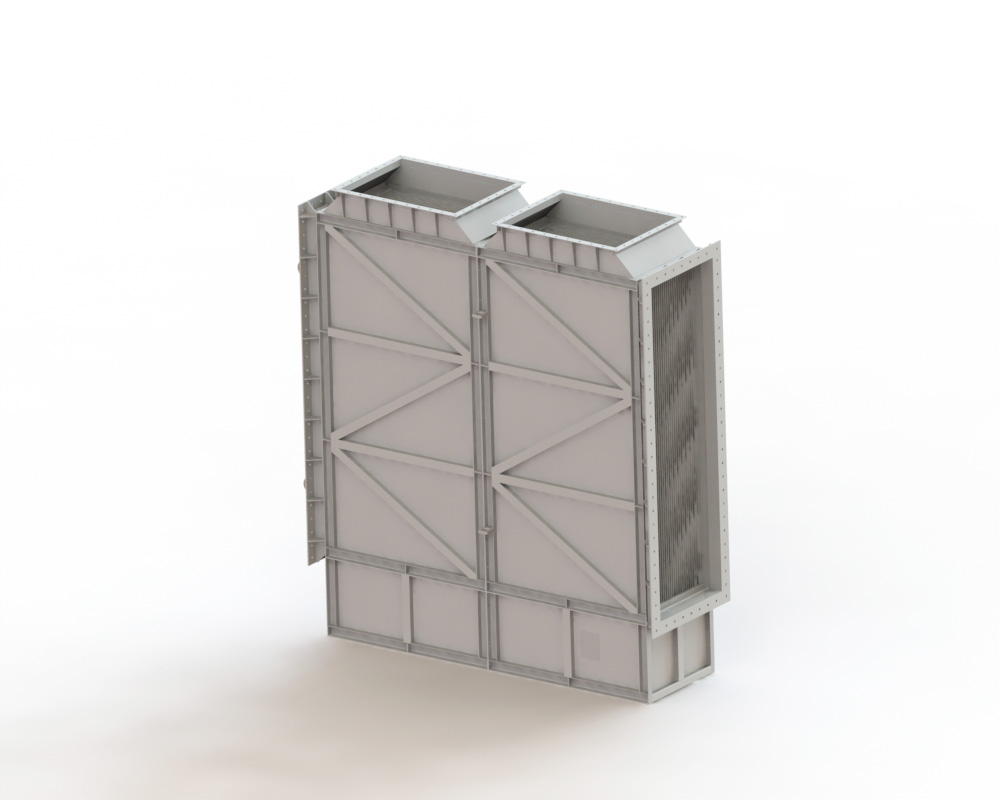

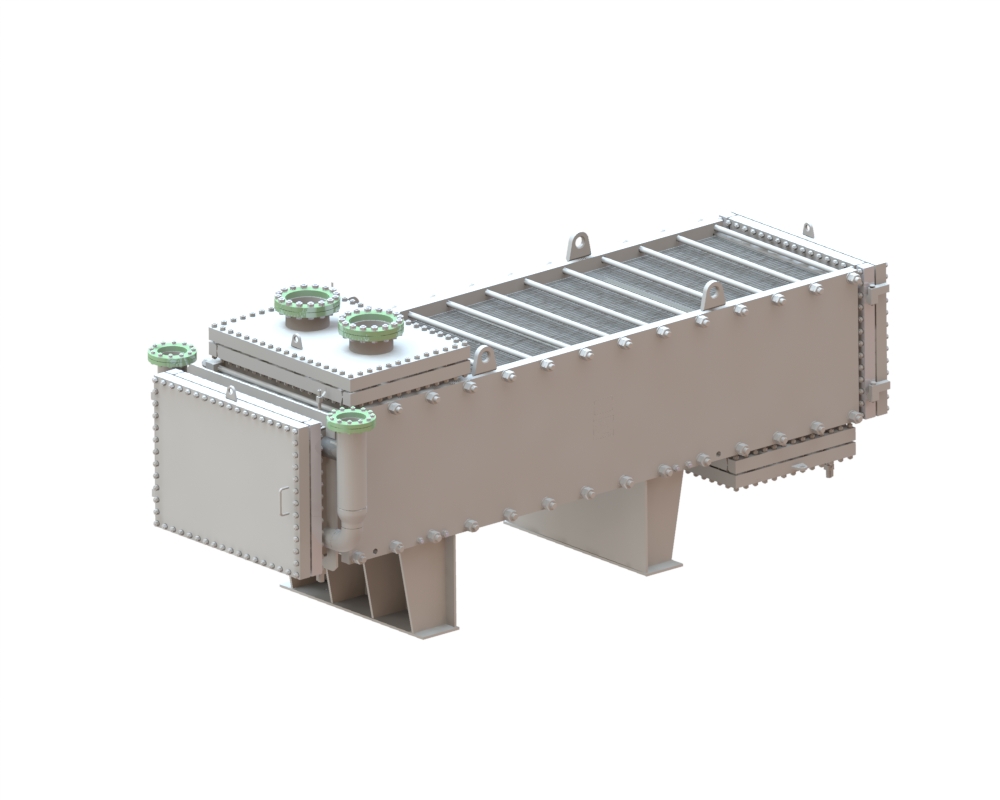

☆ The main heat transfer element, ie. flat plate or corrugated plate are welded together or mechanically fixed to form plate pack. The modular design of the product makes the structure flexible. The unique AIR FILMTM technology solved the dew point corrosion. Air preheater is widely used in oil refinery, chemical, steel mill, power plant, etc.

Application

☆ Reformer furnace for hydrogen, delayed coking furnace, cracking furnace

☆ High temperature smelter

☆ Steel blast furnace

☆ Garbage incinerator

☆ Gas heating and cooling in chemical plant

☆ Coating machine heating, recovery of tail gas waste heat

☆ Waste heat recovery in glass/ceramic industry

☆ Tail gas treating unit of spray system

☆ Tail gas treating unit of non-ferrous metallurgy industry

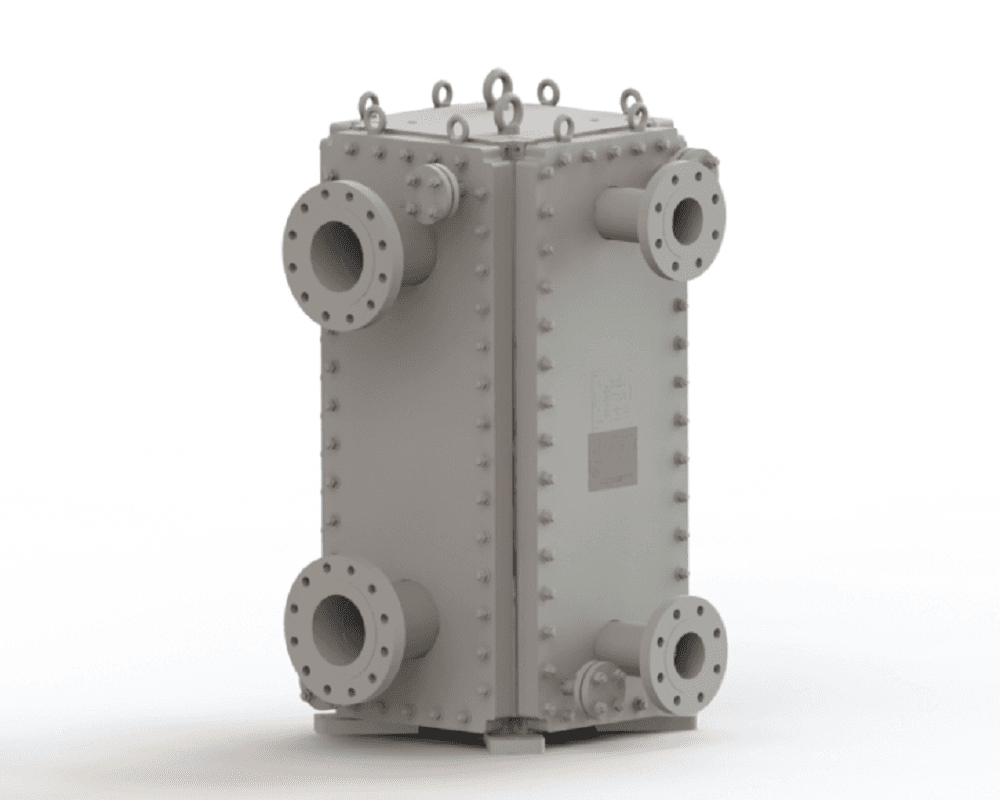

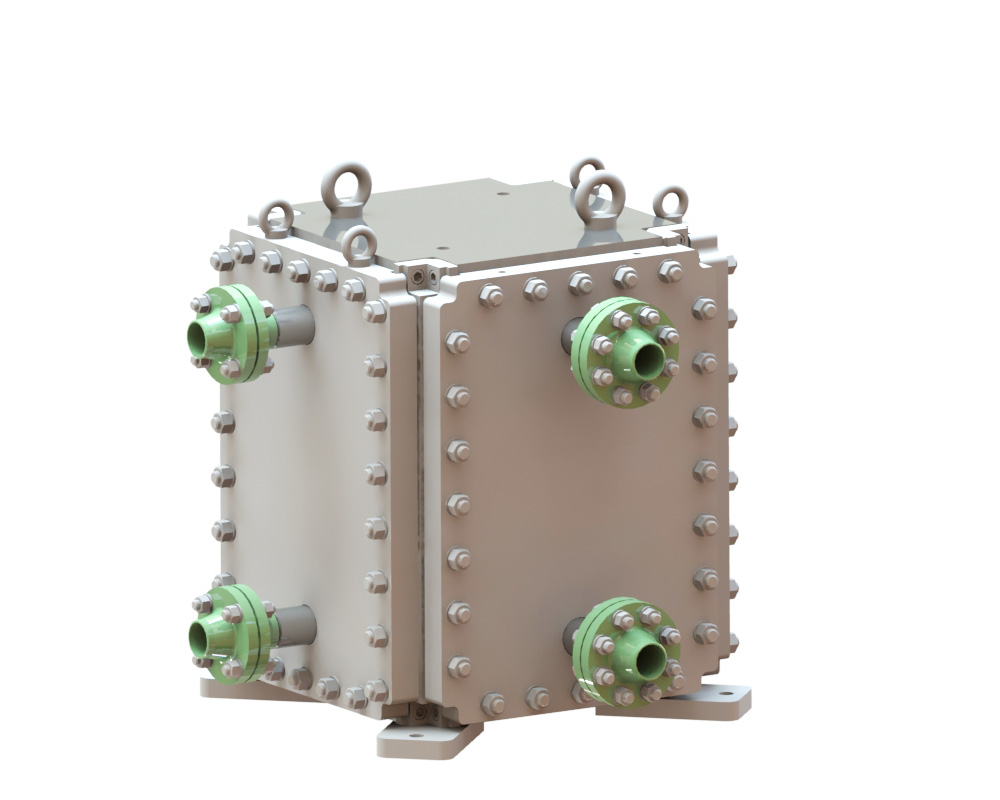

Product detail pictures:

Related Product Guide:

Plate Heat Exchanger made with DUPLATE™ plate

Cooperation

owing to good service, a variety of high quality products, competitive prices and efficient delivery, we enjoy a good reputation among our customers. We are an energetic company with wide market for Massive Selection for Gas Heat Exchanger Design - Plate type Air preheater for Reformer Furnace – Shphe , The product will supply to all over the world, such as: Swiss , Armenia , Botswana , Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.