Ut instrumentum refrigerationis intermedium in processu decompositionis industriae aluminae, permutator caloris laminarum latarum ob magnam efficaciam transmissionis caloris, facilem purgationem, et structuram specialem canalis lati sine contactu magis magisque adhibitus est. Attamen, cum qualitas mineralis decrescit, necessitas augendi productionem orta est, laminae permutatoris caloris laminarum latarum planae sunt, quod efficit ut materia sordida in canali deponatur, quod ad consequentias reductionis efficaciae transmissionis caloris, abrasionis, et purgationis frequentis ducit. Ut problema obstructionis fundamentaliter solvatur et cyclus purgationis atque vita utilis instrumenti augeatur,collocatio verticalis laminarumetreductio fluxus pulmentioptima solutio est ad supradicta problemata solvenda.

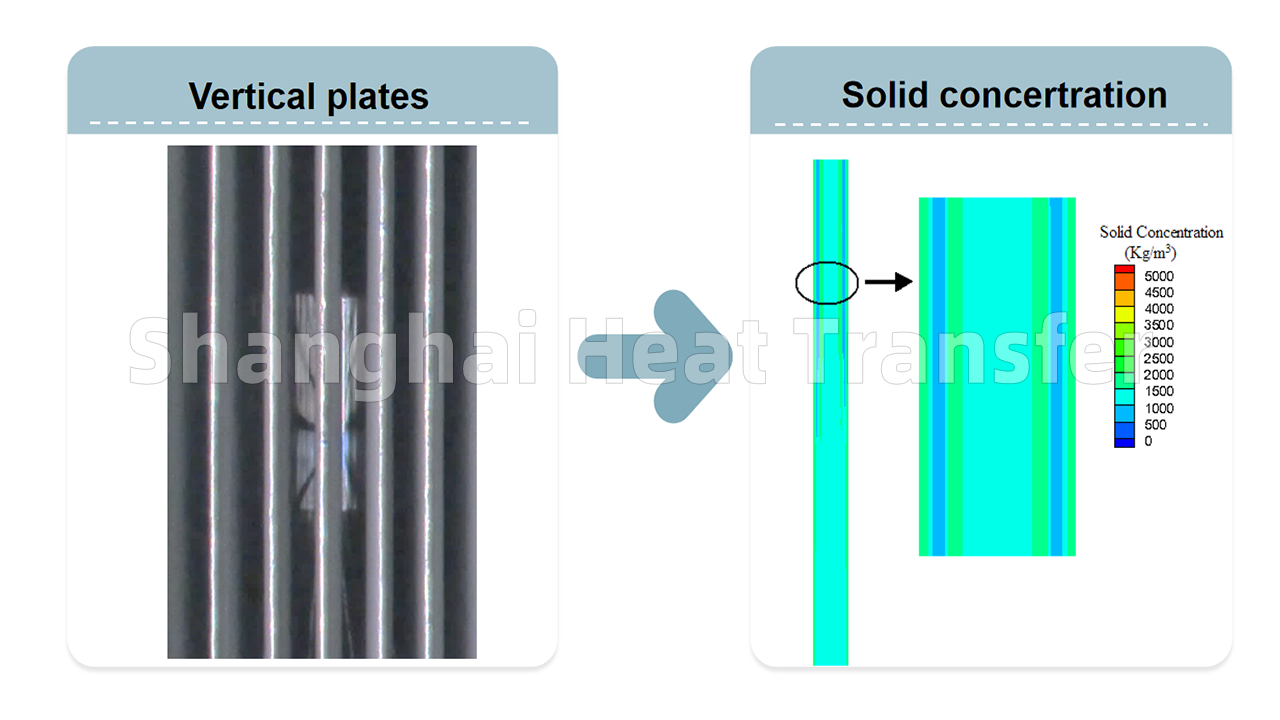

Verticaliter pone ut in figura demonstratur.

Analysis fluxus:

Cum medium operans biphasicum solidum et liquidum a summo ad imum fluit, directio actionis gravitatis particularum solidarum cum directione fluxus congruens est, depositio non fiet. Quia vis trahens in particulis solidis effectum gravitatis earum omnino impedire potest, et parva velocitas fluxus omnes particulas solidas suspendere potest.

Cum distributio particularum relative uniformis est, nulla area accumulationis particularum significativa vel nulla area particularum in canali est, nec ulla area manifesta altae soliditatis contentae prope laminam est, ita efficientia translationis caloris augetur. Post clausuram, lutum leniter sub propria gravitate emittitur, et...nulla difficultas depositionis lutiintra apparatum.

Uno verbo, innixi hereditate et retentione commodorum permutatoris caloris laminarum horizontalium latarum.,ille/illa/illudcommutator caloris laminae verticalis latae spatiimeliorationem qualitativam in aspectibus effecitcontra obstructionem, contra abrasionem et commodam sustentationemPatet permutatorem caloris laminarum verticalium latae rimae novum postulatum esse apparatuum refrigerationis intermediae, quia non solum cyclum purgationis et vitam utilem prolongat, sed etiam problemata obstructionis et abrasionis omnino solvit.

Tempus publicationis: II Augusti, MMXXII