Ọrịre na-ekpo ọkụ maka evaporator mmiri mkpofu - Ọpụpụ dị obosara welded Plate Heat Exchanger maka ụlọ nrụpụta Alumina – Shphe

Ọrịre na-ekpo ọkụ maka evaporator mmiri mkpofu - Ọpụpụ dị ukwuu welded Plate Heat Exchanger maka ụlọ nrụpụta Alumina - Nkọwa Shphe:

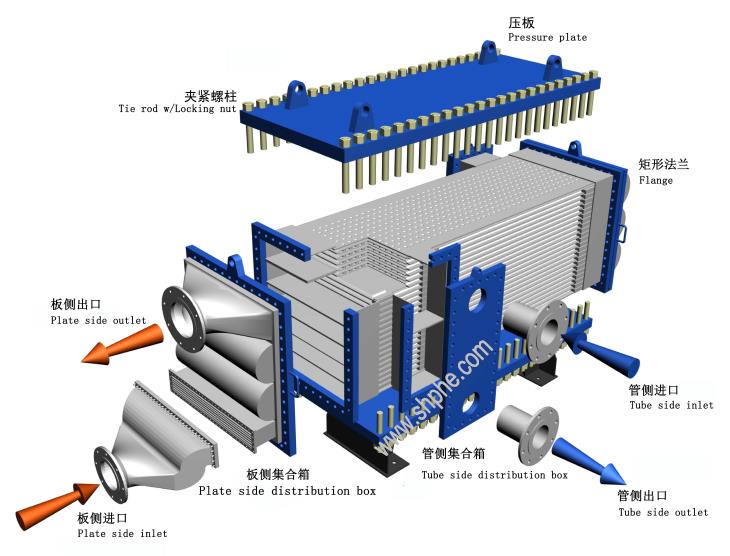

Kedu ka o si arụ ọrụ?

Enwere ike iji ihe na-ekpo ọkụ na-ekpo ọkụ efere efere maka ọgwụgwọ okpomọkụ dị ka ikpo ọkụ na oyi na-ekpo ọkụ nke viscous ma ọ bụ ọkara nwere ihe ndị na-adịghị ahụkebe na eriri nkwusioru na shuga, ime akwụkwọ, metallurgy, ethanol na ụlọ ọrụ kemịkalụ.

Nhazi pụrụ iche nke efere mgbanwe okpomọkụ na-eme ka ọ dị mma ịnyefe ọkụ ọkụ na nkwụsị nrụgide karịa ụdị ndị ọzọ nke ikpo ọkụ ọkụ n'otu ọnọdụ ahụ. A na-ahụkwa na ọ dị mma na-asọba nke mmiri na ọwa oghere sara mbara. Ọ na-aghọta ebumnobi nke mba “ebe nwụrụ anwụ” na enweghị nkwụnye ego ma ọ bụ mgbochi nke ụmụ irighiri ihe ma ọ bụ nkwusioru.

A na-emepụta ọwa dị n'otu akụkụ n'etiti efere dị larịị na efere dị larịị nke jikọtara ya na stud. A na-emepụta ọwa dị n'akụkụ nke ọzọ n'etiti efere dị larịị nke nwere oghere sara mbara, na enweghị ebe kọntaktị. Ma ọwa bụ adabara elu viscous ọkara ma ọ bụ ọkara nwere keadighi rarii ahụ na eriri.

Ngwa

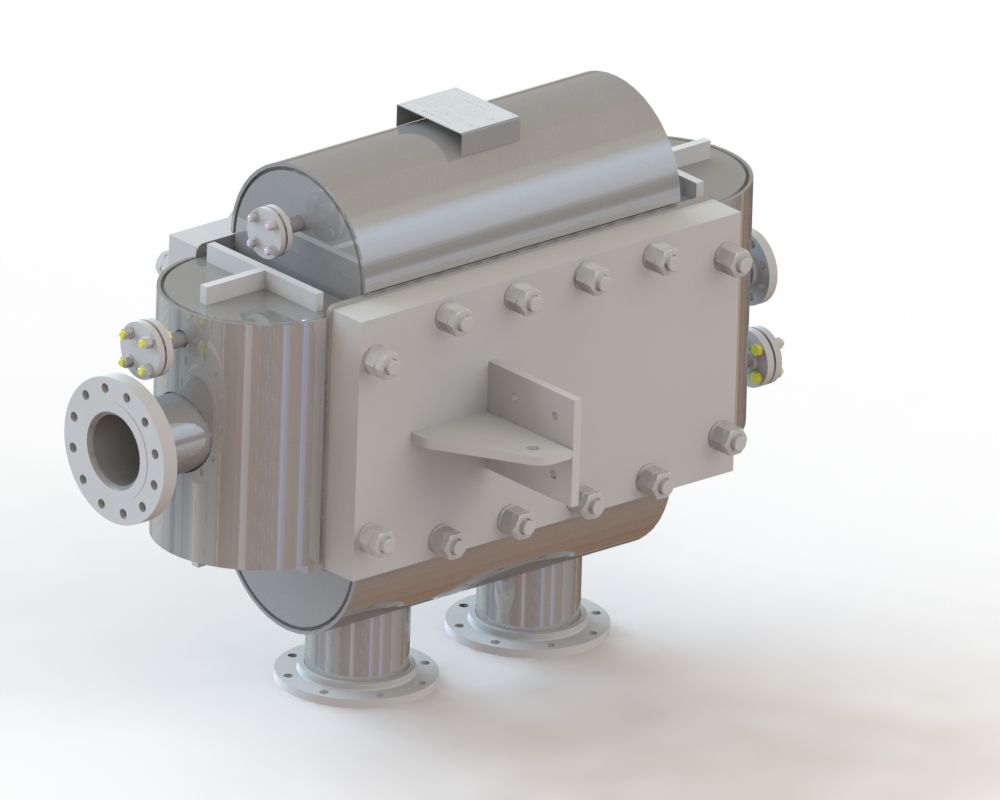

Alumina, tumadi aja alumina, bụ akụrụngwa maka alumina electrolysis. Enwere ike ịhazi usoro mmepụta nke alumina dị ka ngwakọta Bayer-sintering. Ngwa nke ihe na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na ụlọ ọrụ alumina na-eme nke ọma na-ebelata mbuze na mgbochi, nke na-eme ka ọkụ na-ekpo ọkụ na-arụ ọrụ na-arụ ọrụ yana mmepụta mmepụta ihe.

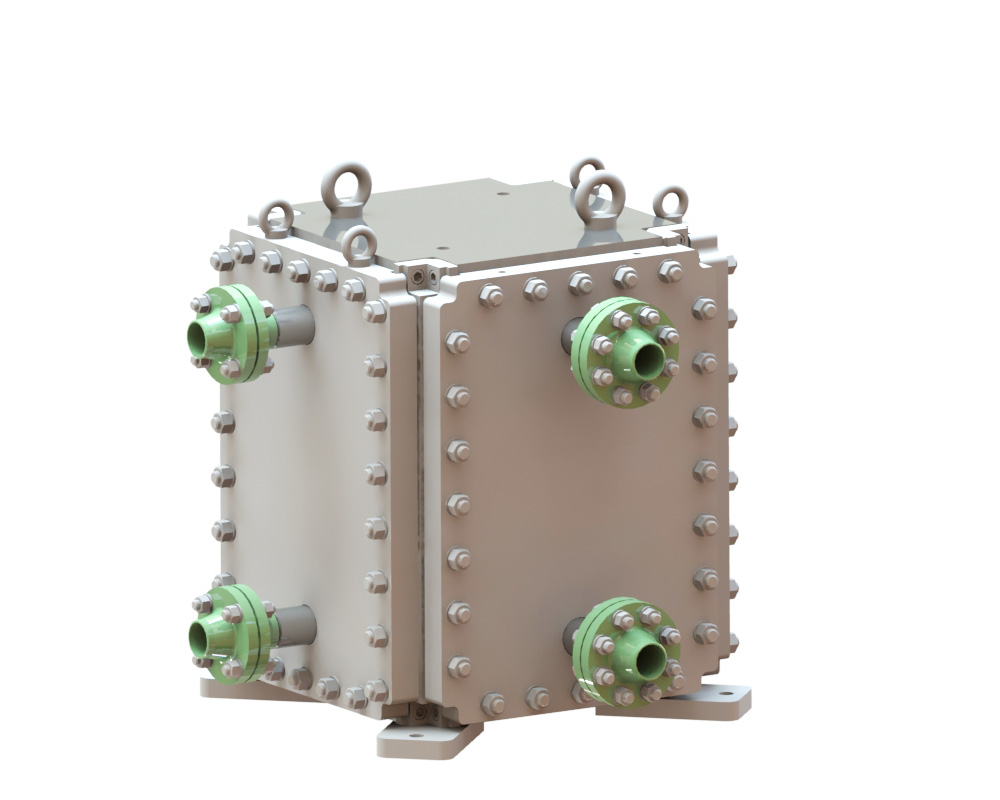

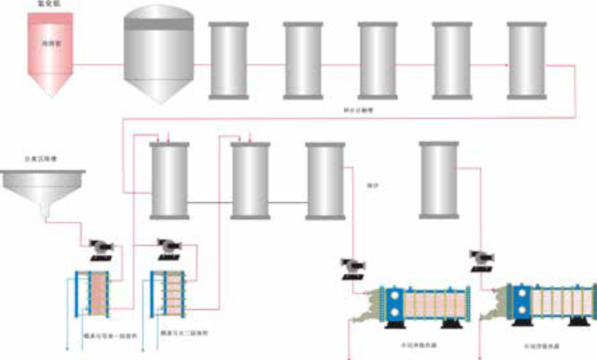

A na-etinye ihe ndị na-ekpo ọkụ efere efere dị ka PGL jụrụ oyi, agglomeration jụrụ na interstage jụrụ.

A na-etinye onye na-ekpo ọkụ na-ekpo ọkụ na etiti etiti okpomọkụ dobe ogbako na nbibi na nhazi usoro ọrụ na usoro mmepụta nke alumina, nke a na-etinye n'elu ma ọ bụ ala nke tankị decomposition ma jiri ya mee ihe maka ibelata okpomọkụ nke aluminum hydroxide slurry na nhazi usoro.

Igwe nju oyi dị n'ime ụlọ alumina

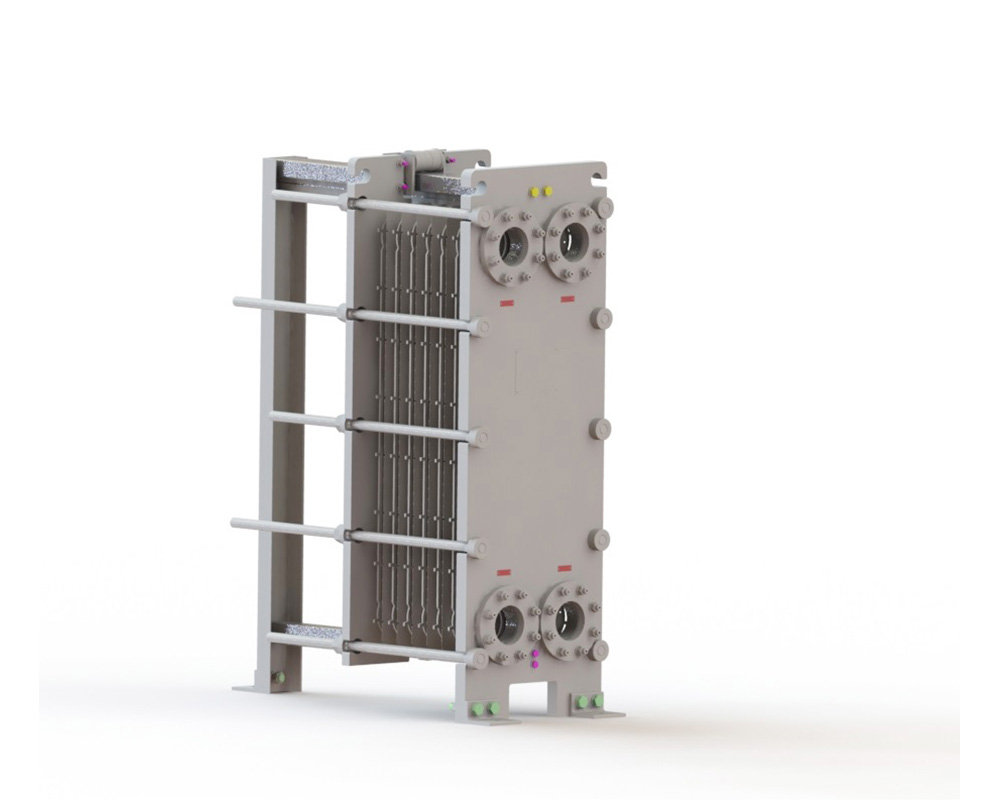

Foto nkọwa ngwaahịa:

Ntuziaka ngwaahịa emetụtara:

Imekọ ihe ọnụ

Plate Heat Exchanger ejiri efere DUPLATE™ mee

Anyị nwere ahụmahụ emeputa. Wining the most of your crucial certifications of its market for Hot Sale for Wastewater Evaporator - Wide Gap Welded Plate Heat Exchanger for Alumina refinery – Shphe , The ngwaahịa ga-eweta n'ụwa nile, dị ka: Armenia , Burundi , Bolivia , Our company abides by the management idea of " keep innovation, follow excellence". Na ndabere nke na-emesi uru nke ngwaahịa dị ugbu a, anyị na-anọgide na-ewusi ike na ịgbatị mmepụta ngwaahịa. Ụlọ ọrụ anyị na-ekwusi ike na ihe ọhụrụ iji kwalite mmepe mmepe nke ụlọ ọrụ, ma mee ka anyị bụrụ ndị na-ebubata ihe dị elu nke ụlọ.

Ụlọ ọrụ a nwere echiche nke "mma mma, ọnụ ahịa nhazi dị ala, ọnụ ahịa dị mma karịa", ya mere ha nwere àgwà ngwaahịa na ọnụahịa asọmpi, nke ahụ bụ isi ihe mere anyị ji họrọ imekọ ihe ọnụ.