Ọrịre na-ekpo ọkụ maka Ikuku gaa na mmiri na-agbanwe ọkụ - Ọpụrụiche dị n'ụdị welded Plate Heat Exchanger maka ụlọ nrụpụta Alumina - Shphe

Ọrịre na-ekpo ọkụ maka Ikuku gaa na mmiri na-agbanwe ọkụ - nnukwu oghere welded Plate Heat Exchanger maka ụlọ nrụpụta Alumina - Nkọwa Shphe:

Kedu ka o si arụ ọrụ?

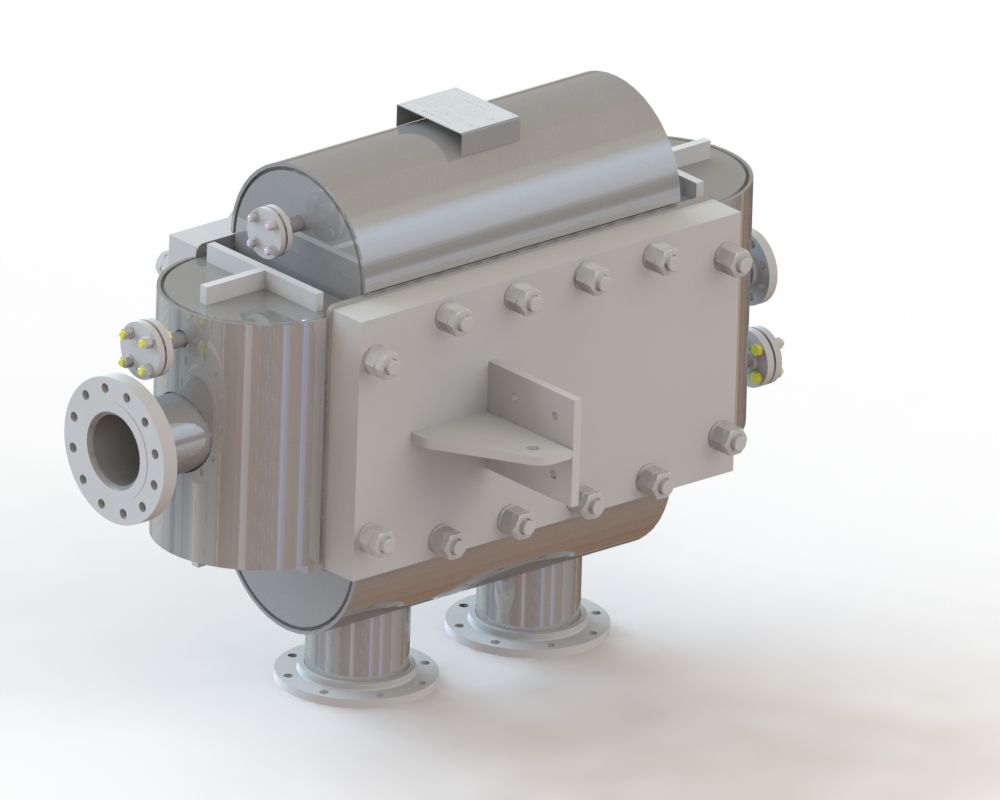

Enwere ike iji ihe na-ekpo ọkụ na-ekpo ọkụ efere efere maka ọgwụgwọ okpomọkụ dị ka ikpo ọkụ na oyi na-ekpo ọkụ nke viscous ma ọ bụ ọkara nwere ihe ndị na-adịghị ahụkebe na eriri nkwusioru na shuga, ime akwụkwọ, metallurgy, ethanol na ụlọ ọrụ kemịkalụ.

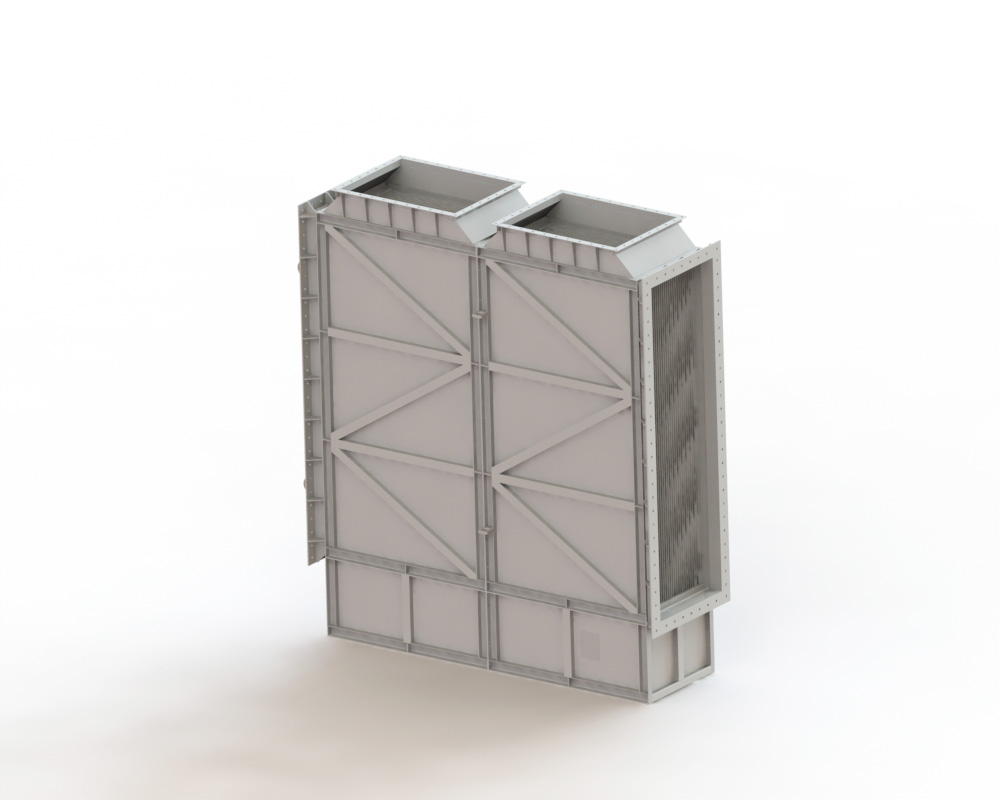

Nhazi pụrụ iche nke efere mgbanwe okpomọkụ na-eme ka ọ dị mma ịnyefe ọkụ ọkụ na nkwụsị nrụgide karịa ụdị ndị ọzọ nke ikpo ọkụ ọkụ n'otu ọnọdụ ahụ. A na-ahụkwa na ọ dị mma na-asọba nke mmiri na ọwa oghere sara mbara. Ọ na-aghọta ebumnobi nke mba “ebe nwụrụ anwụ” na enweghị nkwụnye ego ma ọ bụ mgbochi nke ụmụ irighiri ihe ma ọ bụ nkwusioru.

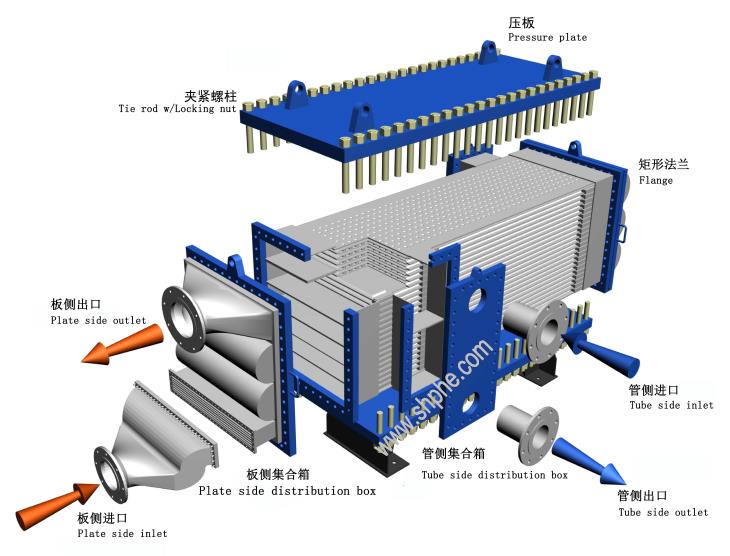

A na-emepụta ọwa dị n'otu akụkụ n'etiti efere dị larịị na efere dị larịị nke jikọtara ya na stud. A na-emepụta ọwa dị n'akụkụ nke ọzọ n'etiti efere dị larịị nke nwere oghere sara mbara, na enweghị ebe kọntaktị. Ma ọwa bụ adabara elu viscous ọkara ma ọ bụ ọkara nwere keadighi rarii ahụ na eriri.

Ngwa

Alumina, tumadi aja alumina, bụ akụrụngwa maka alumina electrolysis. Enwere ike ịhazi usoro mmepụta nke alumina dị ka ngwakọta Bayer-sintering. Ngwa nke ihe na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na ụlọ ọrụ alumina na-eme nke ọma na-ebelata mbuze na mgbochi, nke na-eme ka ọkụ na-ekpo ọkụ na-arụ ọrụ na-arụ ọrụ yana mmepụta mmepụta ihe.

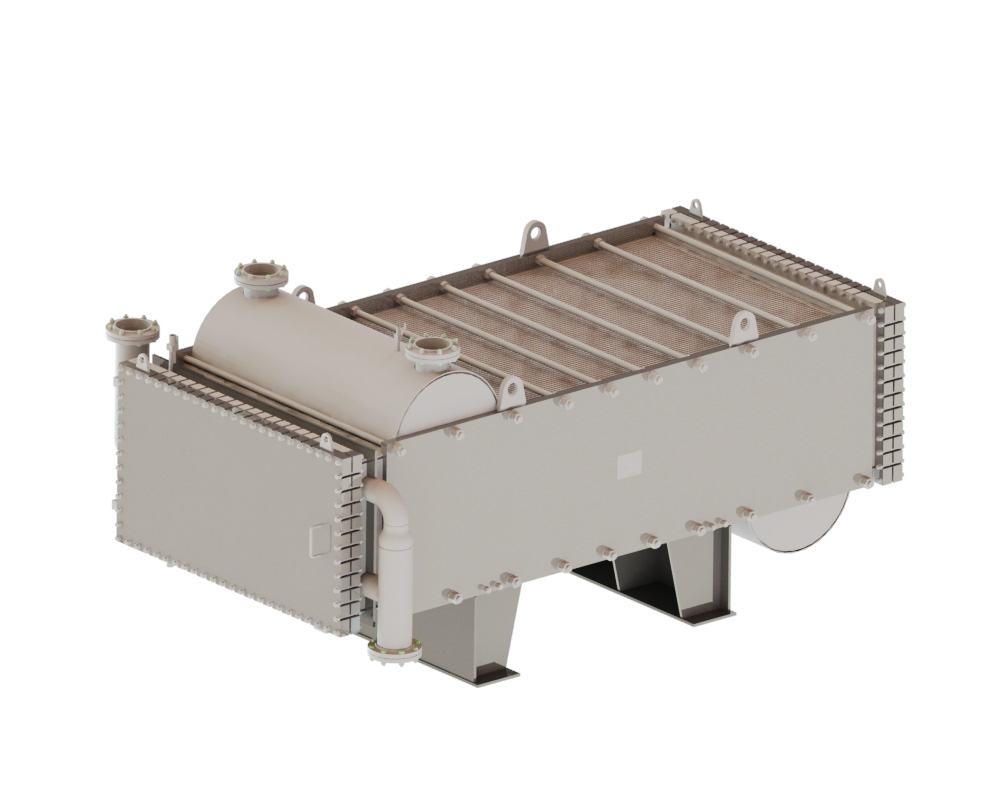

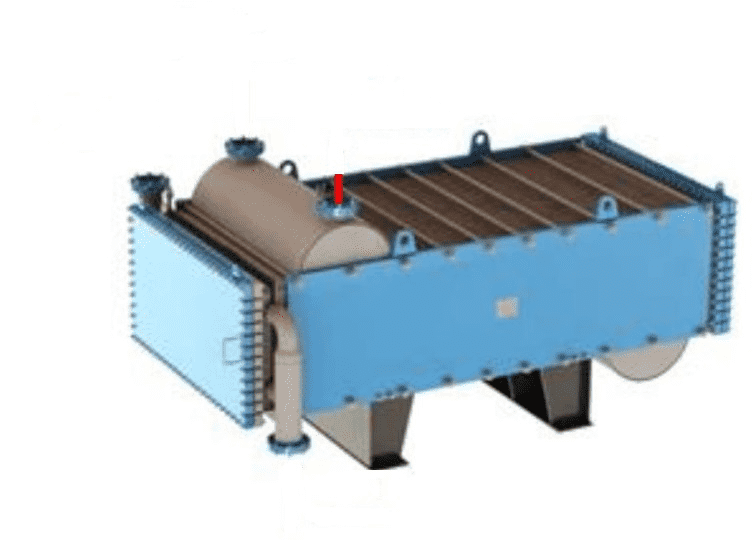

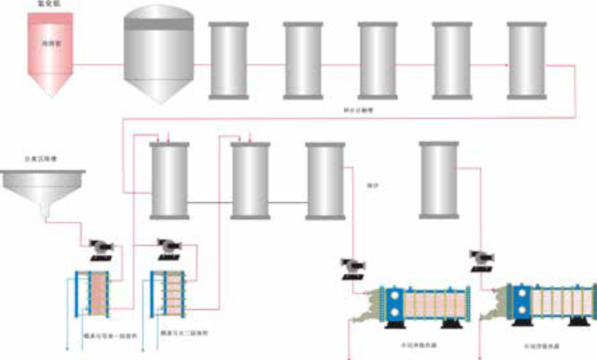

A na-etinye ihe ndị na-ekpo ọkụ efere efere dị ka PGL jụrụ oyi, agglomeration jụrụ na interstage jụrụ.

A na-etinye onye na-ekpo ọkụ na-ekpo ọkụ na etiti etiti okpomọkụ dobe ogbako na nbibi na nhazi usoro ọrụ na usoro mmepụta nke alumina, nke a na-etinye n'elu ma ọ bụ ala nke tankị decomposition ma jiri ya mee ihe maka ibelata okpomọkụ nke aluminum hydroxide slurry na nhazi usoro.

Igwe nju oyi dị n'ime ụlọ alumina

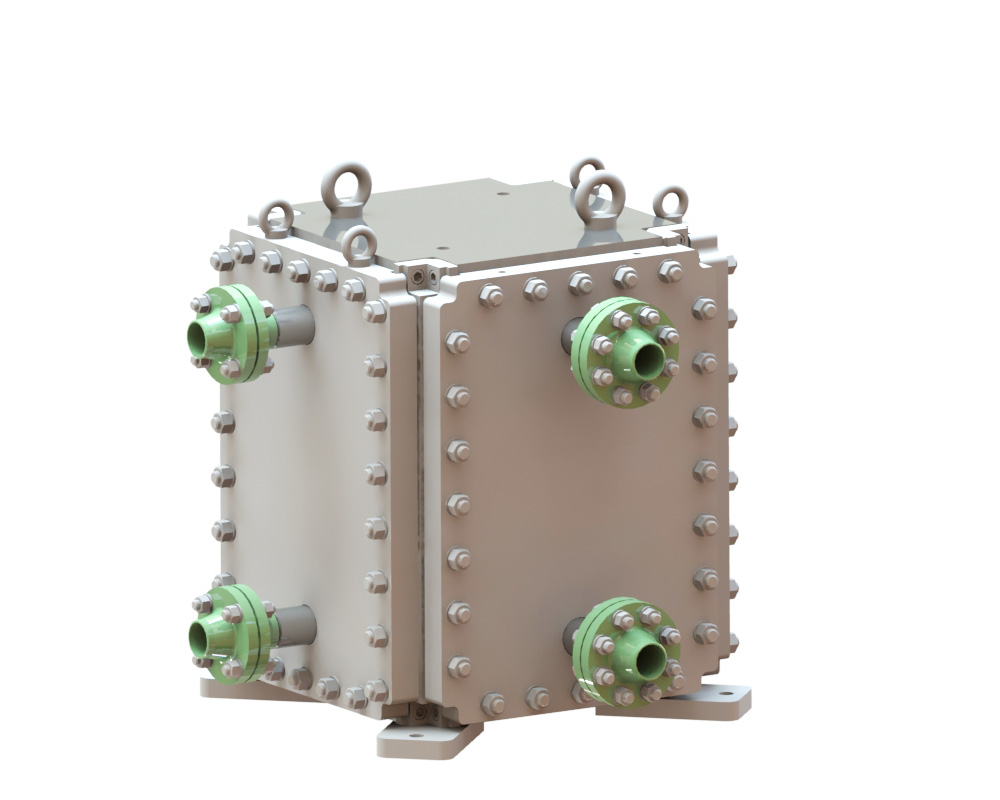

Foto nkọwa ngwaahịa:

Ntuziaka ngwaahịa emetụtara:

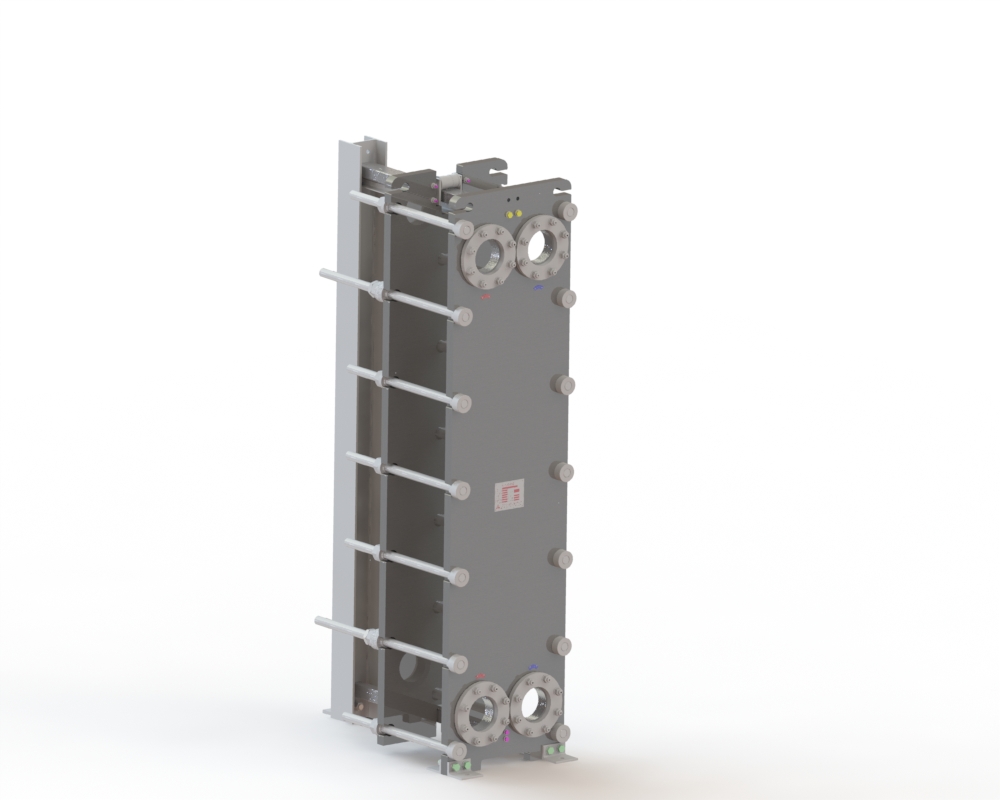

Plate Heat Exchanger ejiri efere DUPLATE™ mee

Imekọ ihe ọnụ

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Hot Sale for Air To Water Heat Exchanger - Wide Gap Welded Plate Heat Exchanger for Alumina refinery – Shphe , The ngwaahịa ga-enye n'ụwa nile, dị ka: Japan , Cape Town , Sri Lanka , Anyị na-enye gị OEM ọrụ kpọmkwem chọrọ na caters. Site na otu siri ike nke ndị injinia nwere ahụmahụ na nhazi na mmepe hose, anyị ji ohere ọ bụla na-enye ngwaahịa kacha mma maka ndị ahịa anyị.

N'ime ndị na-ere ahịa na-arụkọ ọrụ ọnụ, ụlọ ọrụ a nwere àgwà kachasị mma na ọnụahịa ezi uche dị na ya, ha bụ nhọrọ mbụ anyị.