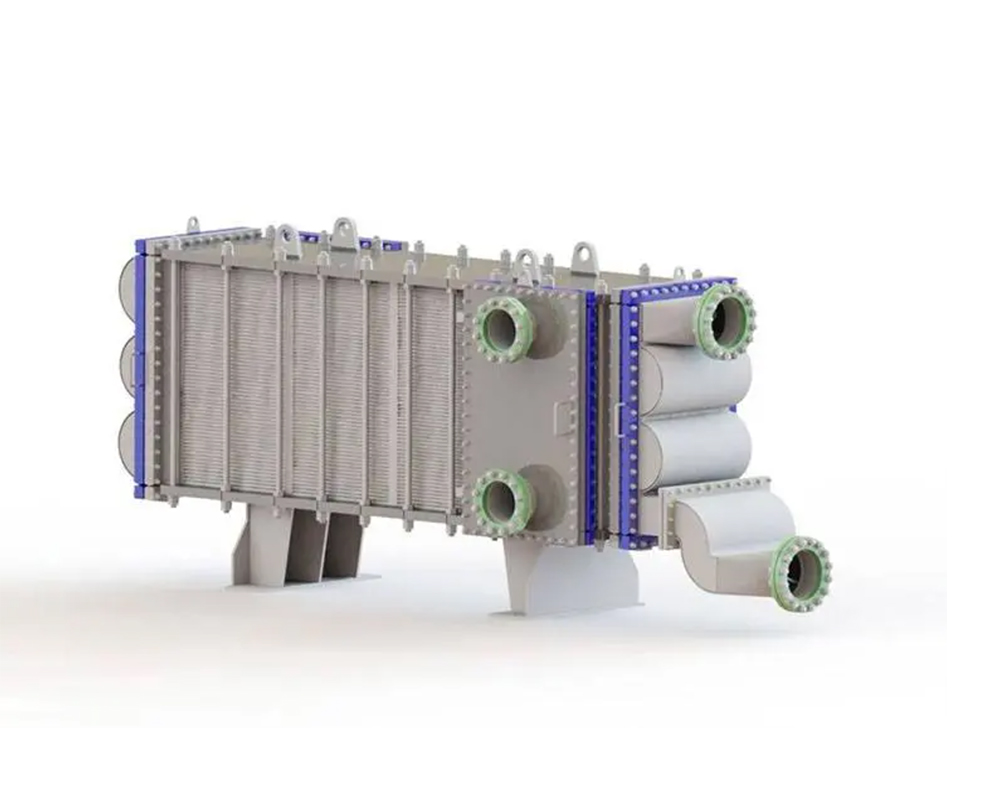

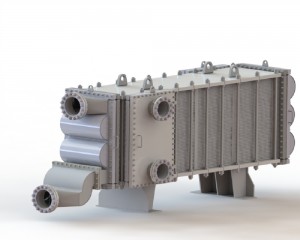

Horizontal Precipitation Slurry Cooler in Alumina Refinery

Kaʻina hana o ka alumina

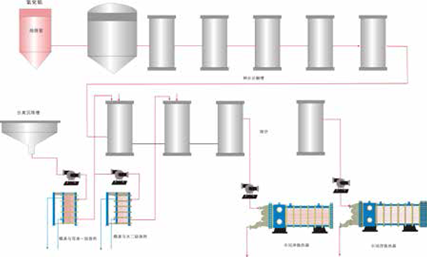

ʻO ka alumina, ka nui o ke one alumina, ka mea maka no ka electrolysis alumina. Hiki ke helu ʻia ke kaʻina hana o ka alumina ma ke ʻano he hui Bayer-sintering. Hoʻohana ʻia ʻo Wide Gap Welded Plate Heat Exchanger ma ka Precipitation area i ke kaʻina hana o ka alumina, i kau ʻia ma luna a i lalo paha o ka pahu decomposition a hoʻohana ʻia no ka hoʻohaʻahaʻa ʻana i ka mahana o ka alumini hydroxide slurry i ke kaʻina decomposition.

No ke aha ka mea hoʻololi wela o ka pā ākea ākea?

ʻO ka hoʻohana ʻana i ka Wide Gap Welded Plate Heat Exchanger i loko o ka hoʻoheheʻe alumina e hoʻemi maikaʻi i ka ʻino a me ka hoʻopaʻa ʻana, ʻo ia ka mea e hoʻonui ai i ka maikaʻi o ka hoʻololi ʻana i ka wela a me ka hana hana. ʻO kāna mau hiʻohiʻona nui e pili ana penei:

1. Horizontal structure, High flow rate bring the slurry with solid particles to flow on the surface of plate and effectively reraining the sedimentation and scar.

2. ʻAʻohe wahi hoʻopā ʻana o ka ʻaoʻao awāwa ākea i hiki ai i ka wai ke kahe manuahi a piha i ke ala kahe i hana ʻia e nā papa. ʻAneʻane pili nā papa pāpaʻi a pau i ka hoʻololi ʻana i ka wela, ka mea e ʻike ai i ke kahe ʻole o ka "Dead spots" i ke ala kahe.

3. Aia ka mea hoʻolaha i loko o ka slurry inlet, ka mea e komo ai ka slurry i ke ala like ʻole a hoʻemi i ka erosion.

4. Papa mea: Duplex kila a me 316L.