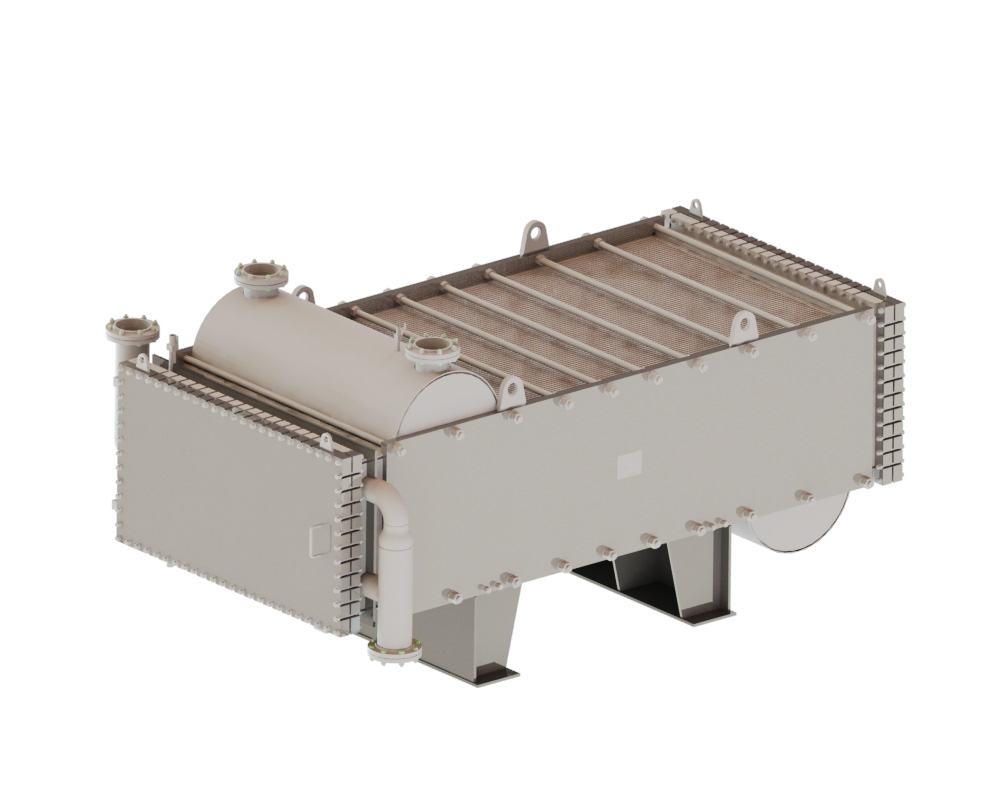

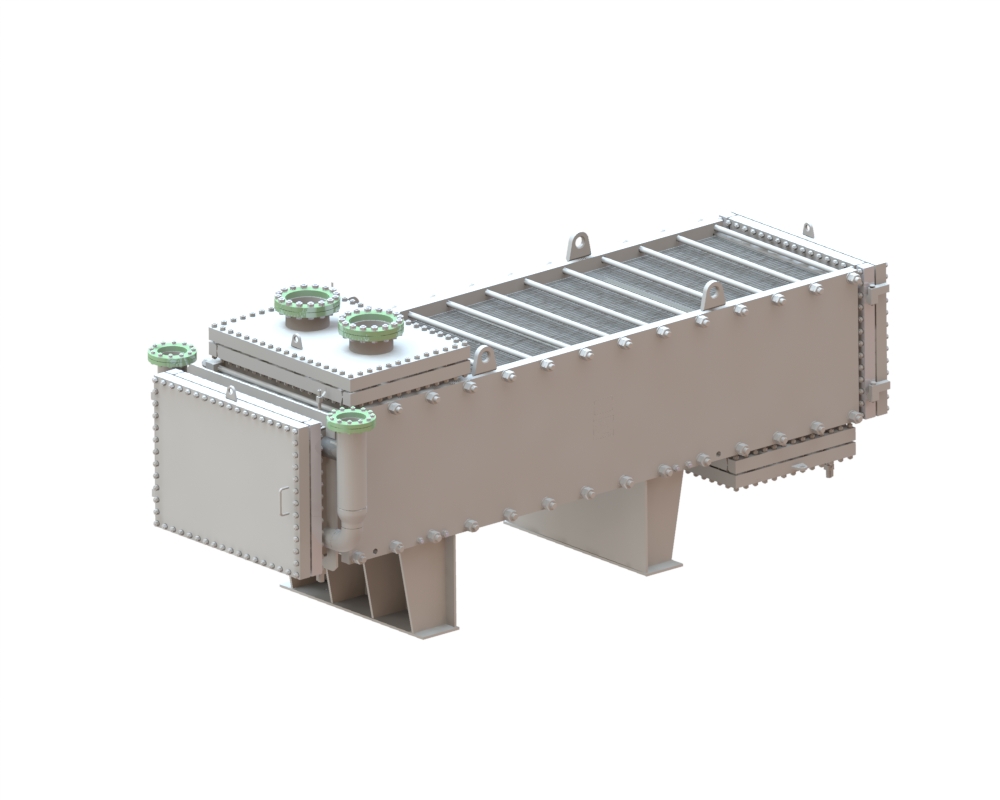

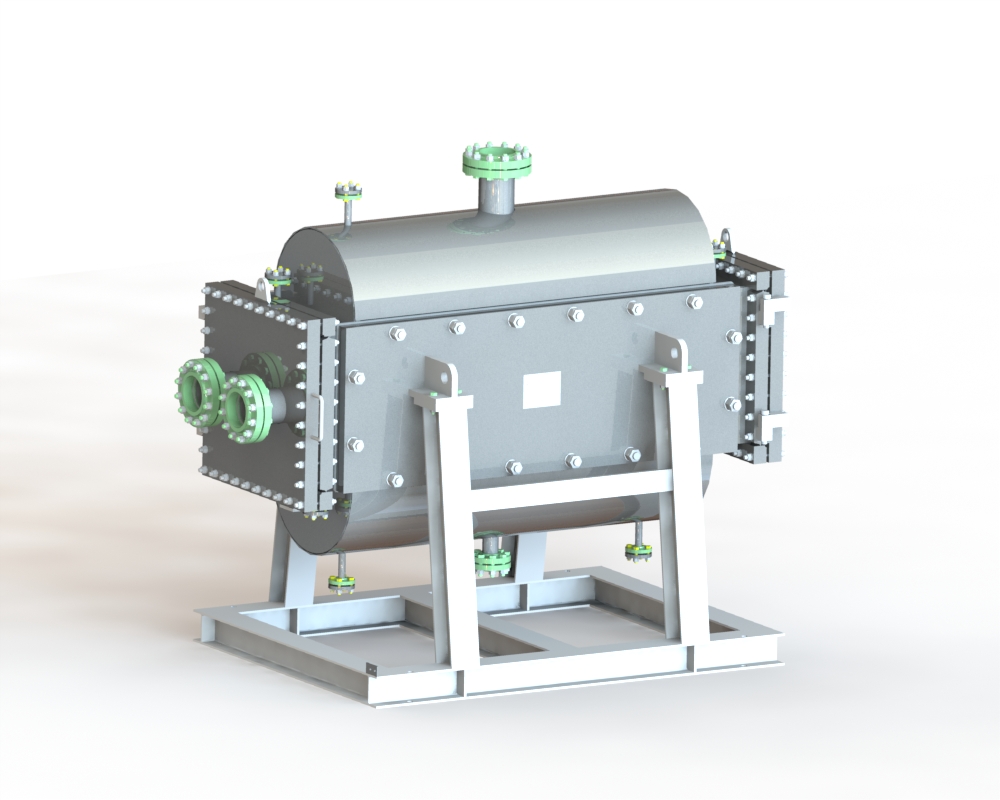

Factory For Oil Furnace Heat Exchanger - Openable TP Fully Welded Plate Heat Exchanger – Shphe

Factory For Oil Furnace Heat Exchanger - Openable TP Fully Welded Plate Heat Exchanger – Shphe Detail:

How it works

Features

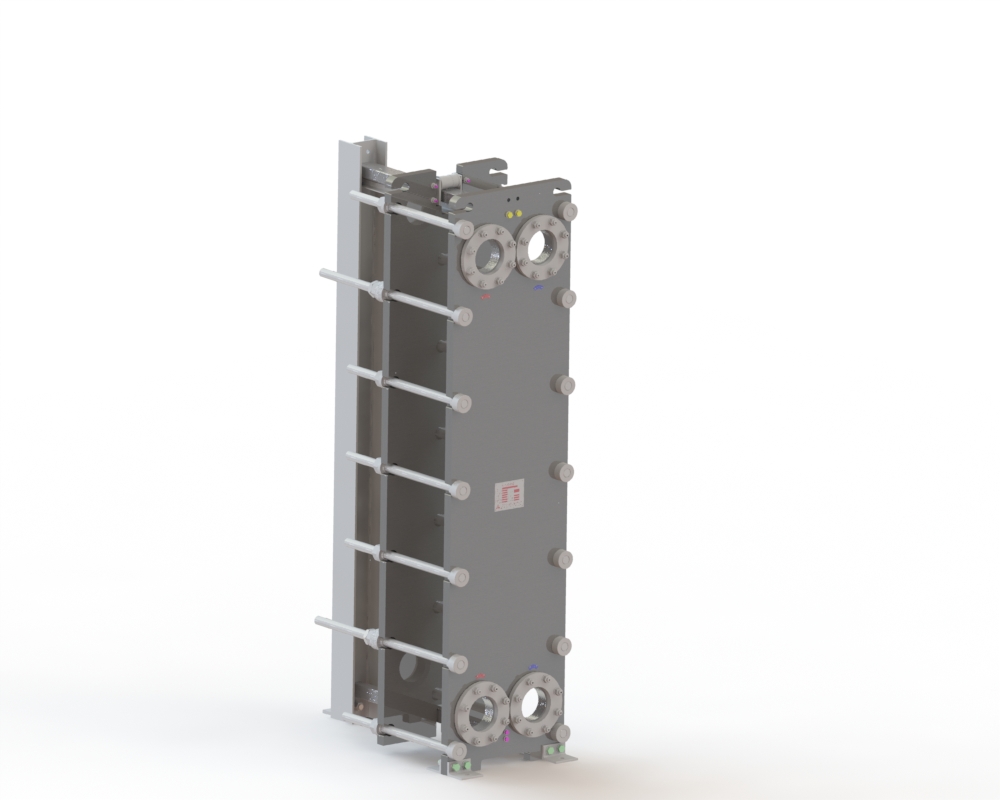

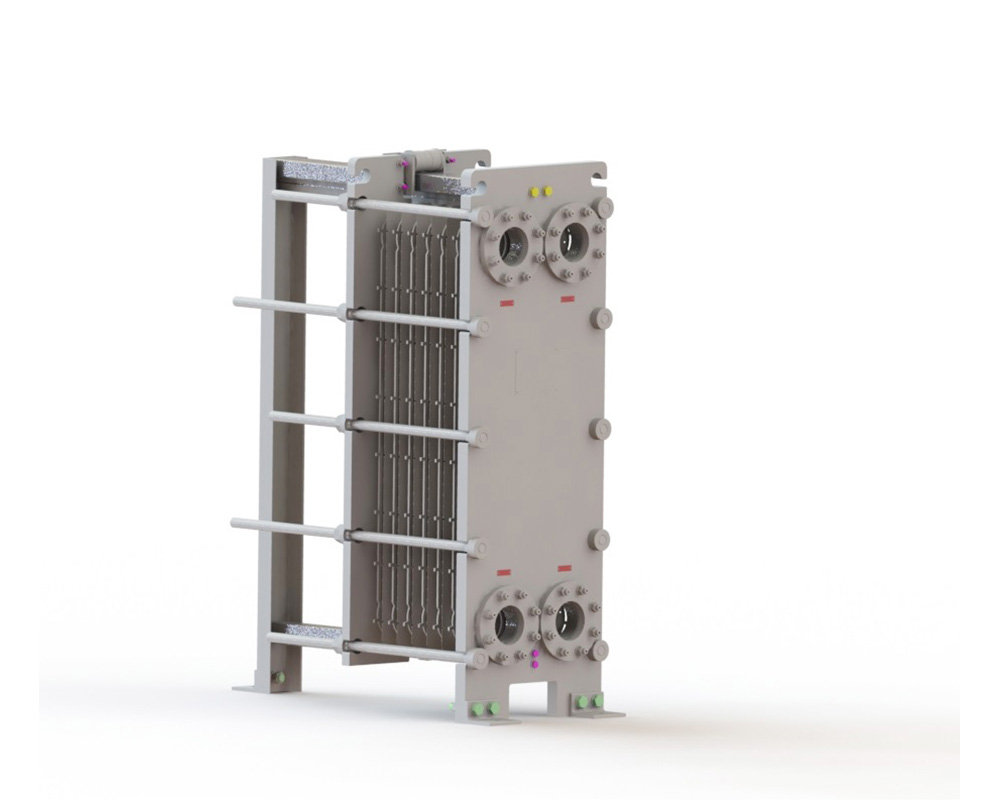

☆ The unique designed plate corrugation form plate channel and tube channel. Two plates stacked to form sine shaped corrugated plate channel, the plate pairs stacked to form elliptically tube channel.

☆ Turbulent Flow in plate channel results high heat transfer efficiency, while tube channel has the feature of small flow resistance and high press. resistant.

☆ Fully welded structure, safe and reliable, suitable for high temp., high press. and hazardous application.

☆ No dead area of flowing, removable structure of tube side facilitate mechanical cleaning.

☆ As condenser, super cooling temp. of steam can be well controlled.

☆ Flexible design, multiple structures, can meet requirement of various process and installation space.

☆ Compact structure with small footprint.

Flexible flow pass configuration

☆ Cross flow of plate side and tube side or cross flow and counter flow.

☆ Multiple plate pack for one heat exchanger.

☆ Multiple pass for both tube side and plate side. Baffle plate can be re-configured to suit changed process requirement.

Range of application

Variable structure

Condenser: for vapor or condensing of organic gas, can meet condensate depression requirement

gas-liquid: for temp. drop or dehumidifier of wet air or flue gas

Liquid-liquid: for high temp., high press.Flammable and explosive process

Evaporator, condenser: one pass for phase change side, high heat transfer efficiency.

Application

☆ Oil refinery

● Crude oil heater, condenser

☆ Oil & gas

● Desulfurization, decarburization of natural gas – lean/rich amine heat exchanger

● Dehydration of natural gas – lean / rich amine exchanger

☆ Chemical

● Process cooling / condensing / evaporation

● Cooling or heating of various chemical substances

● MVR system evaporator, condenser, pre-heater

☆ Power

● Steam condenser

● Lub. Oil cooler

● Thermal oil heat exchanger

● Flue gas condensing cooler

● Evaporator, condenser, heat regenerator of Kalina cycle, Organic Rankine Cycle

☆ HVAC

● Basic heat station

● Press. isolation station

● Flue gas condenser for fuel boiler

● Air dehumidifier

● Condenser, evaporator for refrigeration unit

☆ Other industry

● Fine chemical, coking, fertilizer, chemical fiber, paper & pulp, fermentation, metallurgy, steel, etc.

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Factory For Oil Furnace Heat Exchanger - Openable TP Fully Welded Plate Heat Exchanger – Shphe , The product will supply to all over the world, such as: Spain , Brasilia , Los Angeles , As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.