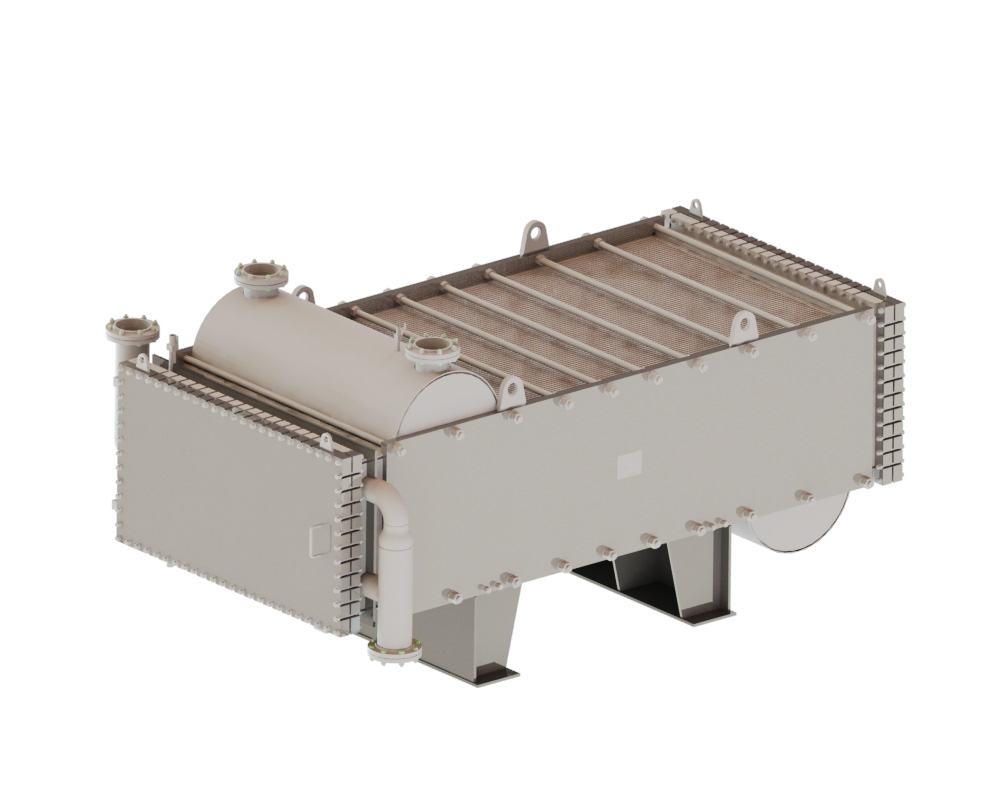

China OEM Spiral Heat Exchanger Paper Industry - TP Fully Welded Plate Heat Exchanger for high temperature and high pressure – Shphe

China OEM Spiral Heat Exchanger Paper Industry - TP Fully Welded Plate Heat Exchanger for high temperature and high pressure – Shphe Detail:

How it works

Features

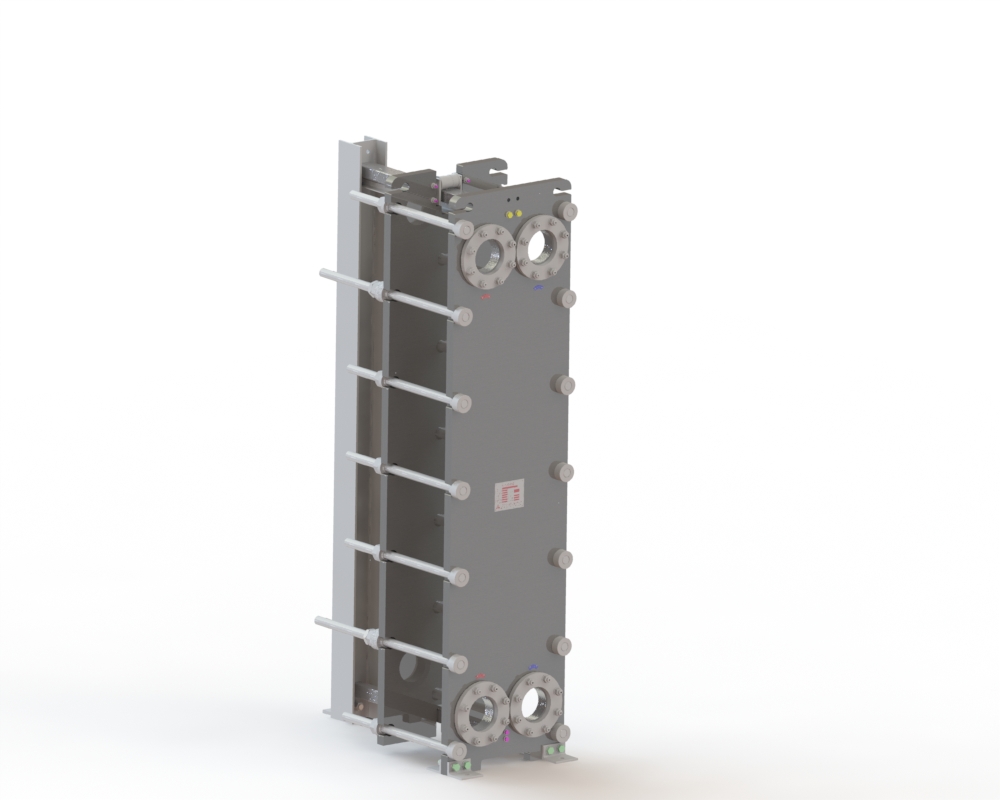

☆ The unique designed plate corrugation form plate channel and tube channel. Two plates stacked to form sine shaped corrugated plate channel, the plate pairs stacked to form elliptically tube channel.

☆ Turbulent Flow in plate channel results high heat transfer efficiency, while tube channel has the feature of small flow resistance and high press. resistant.

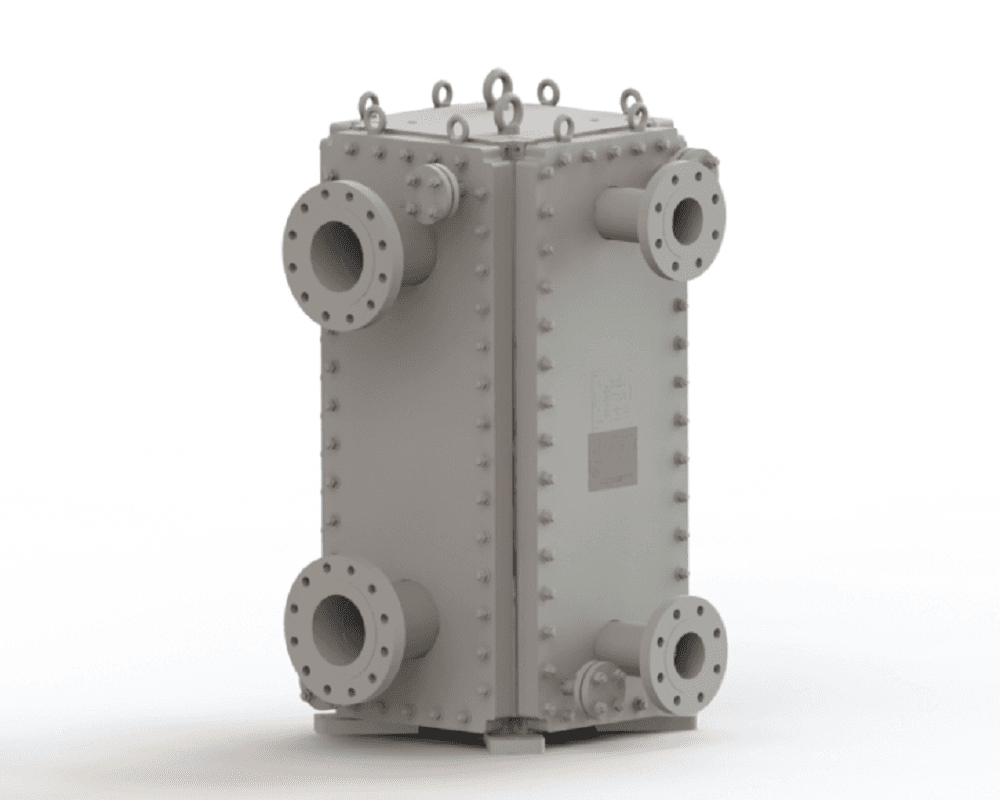

☆ Fully welded structure, safe and reliable, suitable for high temp., high press. and hazardous application.

☆ No dead area of flowing, removable structure of tube side facilitate mechanical cleaning.

☆ As condenser, super cooling temp. of steam can be well controlled.

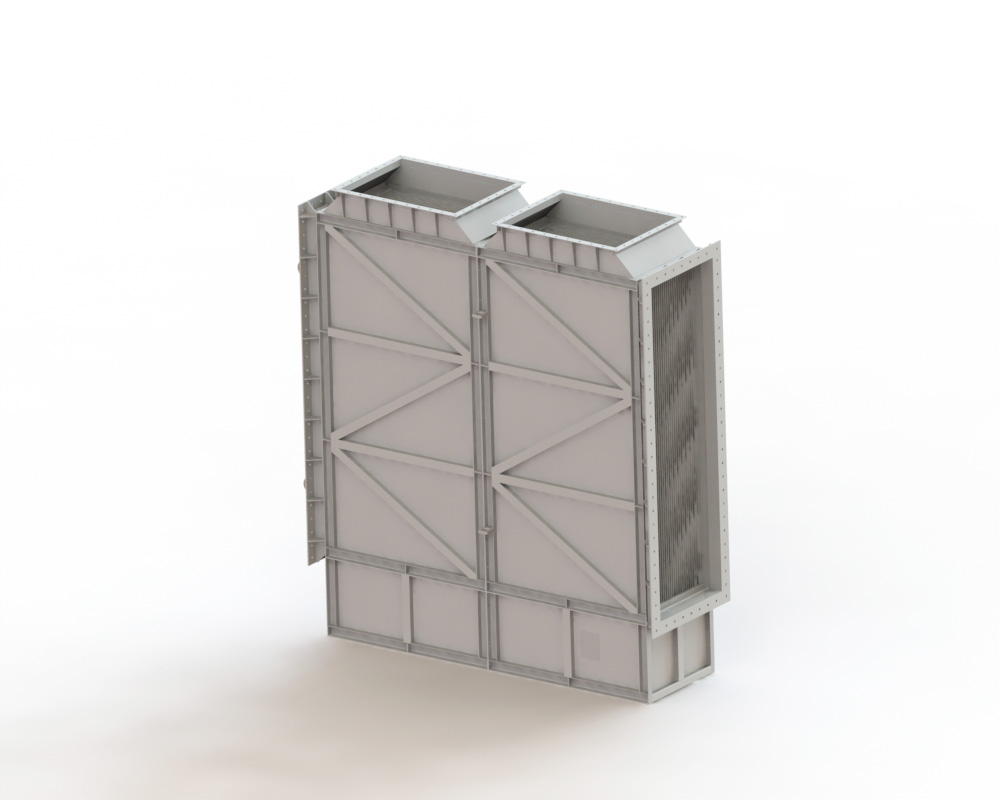

☆ Flexible design, multiple structures, can meet requirement of various process and installation space.

☆ Compact structure with small footprint.

Flexible flow pass configuration

☆ Cross flow of plate side and tube side or cross flow and counter flow.

☆ Multiple plate pack for one heat exchanger.

☆ Multiple pass for both tube side and plate side. Baffle plate can be re-configured to suit changed process requirement.

Range of application

Variable structure

Condenser: for vapor or condensing of organic gas, can meet condensate depression requirement

gas-liquid: for temp. drop or dehumidifier of wet air or flue gas

Liquid-liquid: for high temp., high press.Flammable and explosive process

Evaporator, condenser: one pass for phase change side, high heat transfer efficiency.

Application

☆ Oil refinery

● Crude oil heater, condenser

☆ Oil & gas

● Desulfurization, decarburization of natural gas – lean/rich amine heat exchanger

● Dehydration of natural gas – lean / rich amine exchanger

☆ Chemical

● Process cooling / condensing / evaporation

● Cooling or heating of various chemical substances

● MVR system evaporator, condenser, pre-heater

☆ Power

● Steam condenser

● Lub. Oil cooler

● Thermal oil heat exchanger

● Flue gas condensing cooler

● Evaporator, condenser, heat regenerator of Kalina cycle, Organic Rankine Cycle

☆ HVAC

● Basic heat station

● Press. isolation station

● Flue gas condenser for fuel boiler

● Air dehumidifier

● Condenser, evaporator for refrigeration unit

☆ Other industry

● Fine chemical, coking, fertilizer, chemical fiber, paper & pulp, fermentation, metallurgy, steel, etc.

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction for China OEM Spiral Heat Exchanger Paper Industry - TP Fully Welded Plate Heat Exchanger for high temperature and high pressure – Shphe , The product will supply to all over the world, such as: Armenia , Tunisia , Tunisia , The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.