China OEM Heat Exchanger Machine - Plate type Air preheater for Reformer Furnace – Shphe

China OEM Heat Exchanger Machine - Plate type Air preheater for Reformer Furnace – Shphe Detail:

How it works

☆ Plate type air preheater is a kind of energy saving and environmental protection equipment.

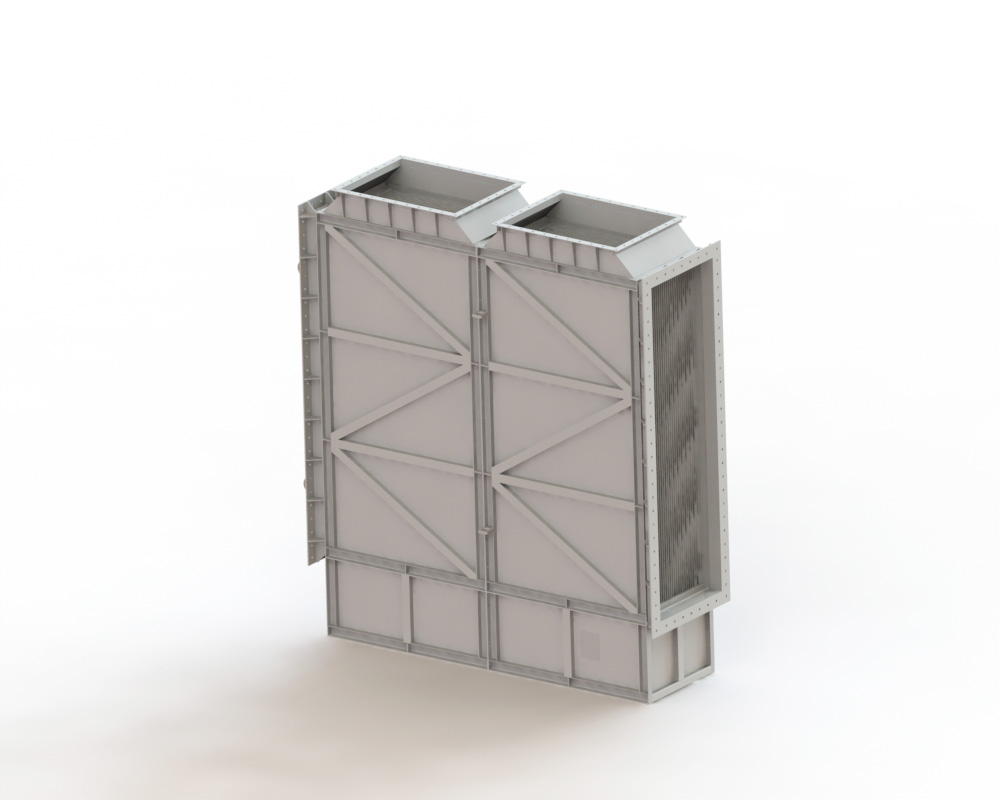

☆ The main heat transfer element, ie. flat plate or corrugated plate are welded together or mechanically fixed to form plate pack. The modular design of the product makes the structure flexible. The unique AIR FILMTM technology solved the dew point corrosion. Air preheater is widely used in oil refinery, chemical, steel mill, power plant, etc.

Application

☆ Reformer furnace for hydrogen, delayed coking furnace, cracking furnace

☆ High temperature smelter

☆ Steel blast furnace

☆ Garbage incinerator

☆ Gas heating and cooling in chemical plant

☆ Coating machine heating, recovery of tail gas waste heat

☆ Waste heat recovery in glass/ceramic industry

☆ Tail gas treating unit of spray system

☆ Tail gas treating unit of non-ferrous metallurgy industry

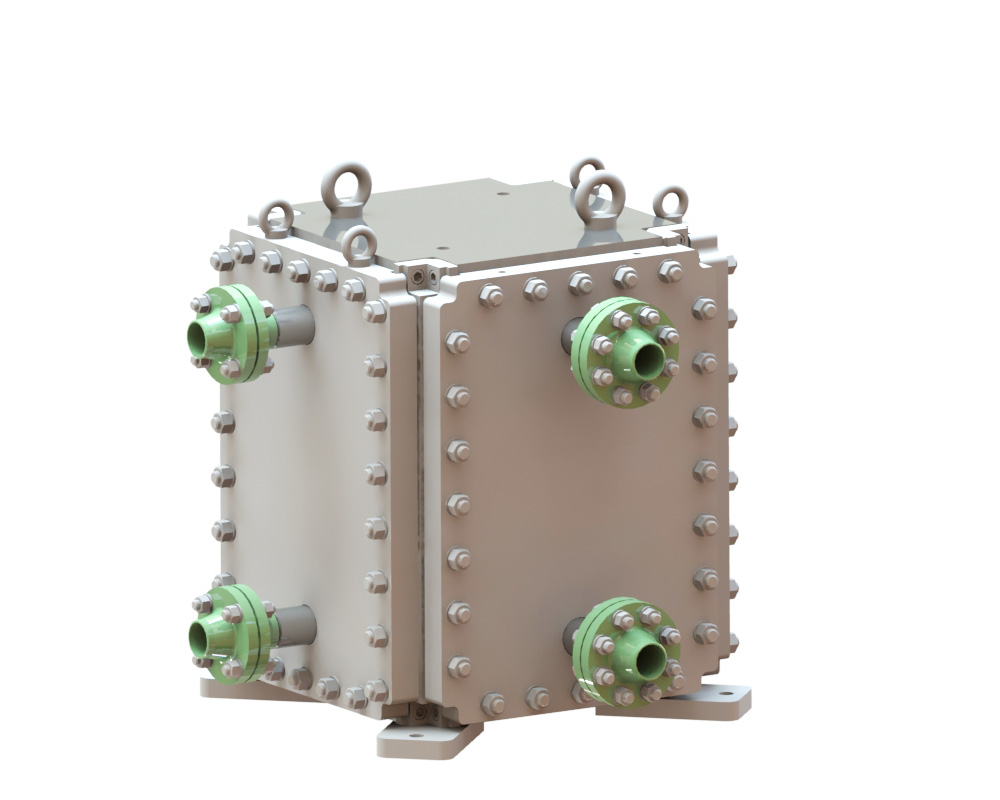

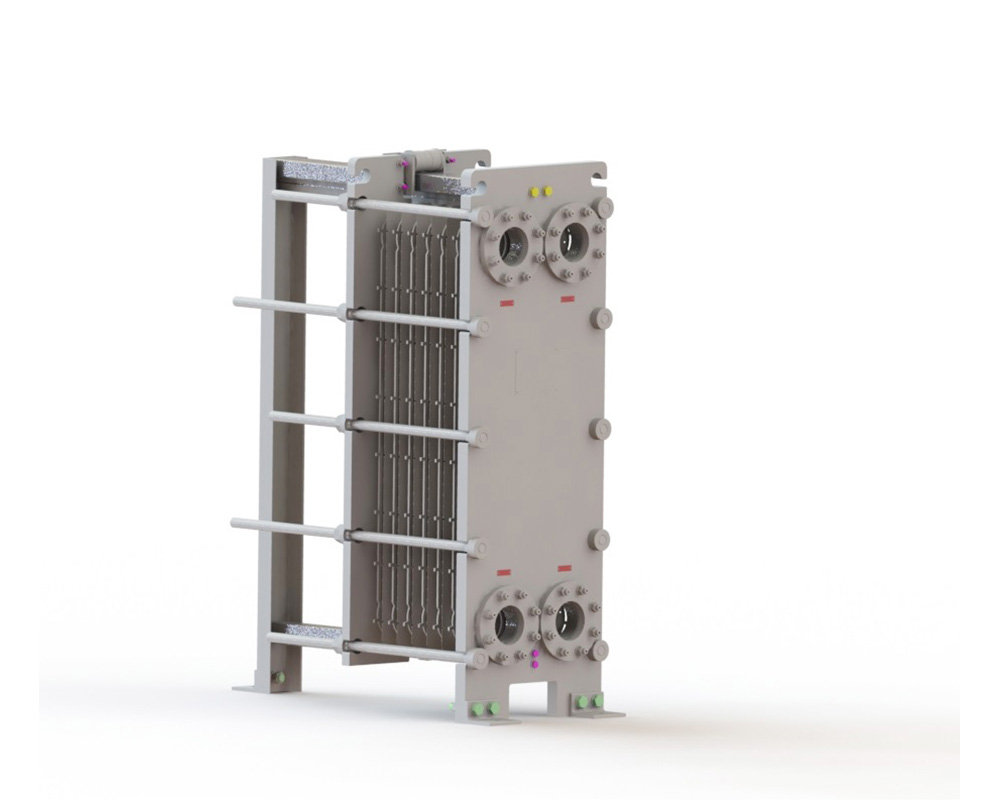

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

We thinks what customers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better good quality, lower processing costs, prices are extra reasonable, won the new and old buyers the support and affirmation for China OEM Heat Exchanger Machine - Plate type Air preheater for Reformer Furnace – Shphe , The product will supply to all over the world, such as: Latvia , Los Angeles , Finland , With good quality, reasonable price and sincere service, we enjoy a good reputation. Products are exported to South America, Australia, Southeast Asia and so on. Warmly welcome customers at home and abroad to cooperate with us for the brilliant future.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!