2019 New Style Plate Heat Eanger For Waste Heat Recovery - Precipitation Cooling Heat Exchanger in Alumina Refinery – Shphe

2019 New Style Plate Heat Eanger For Waste Heat Recovery - Precipitation Cooling Heat Exchanger in Alumina Refinery – Shphe Detail:

Challenge

The challenge before all Alumina Refineries lies in maximizing the yield across precipitation and thereby production while maintaining the quality of alumina tri-hydrate which is either sent to Calcination unit or sold to customers for other applications. Over the last decade or so many Alumina refineries in the world have standardized on use of Inter Stage coolers to achieve this objective by cooling the precipitated slurry in Welded plate heat exchangers. The hydrate particles in the precipitated slurry are abrasive and can gradually wear metal surfaces in heat exchanger surfaces. Additionally, fouling on heat transfer surfaces can occur due to precipitation of aluminum hydroxide and other chemical compounds. This results fouling which reduces the performance of the heat exchanger and overall system performance.

However, periodic corrective steps, which include chemical and mechanical cleaning, can reduce maintenance downtown (i.e. frequency and length). Conversely, heavy fouling combined with limited performance of regular maintenance can decrease heat exchanger efficiency or worse, result in catastrophic heat exchanger failure.

Consequently, Client requests a heat exchanger design to reduce or eliminate: plate fouling, reduce maintenance down time, and heat transfer surface (alloy plate) wear, thereby increasing productivity and system profitability.

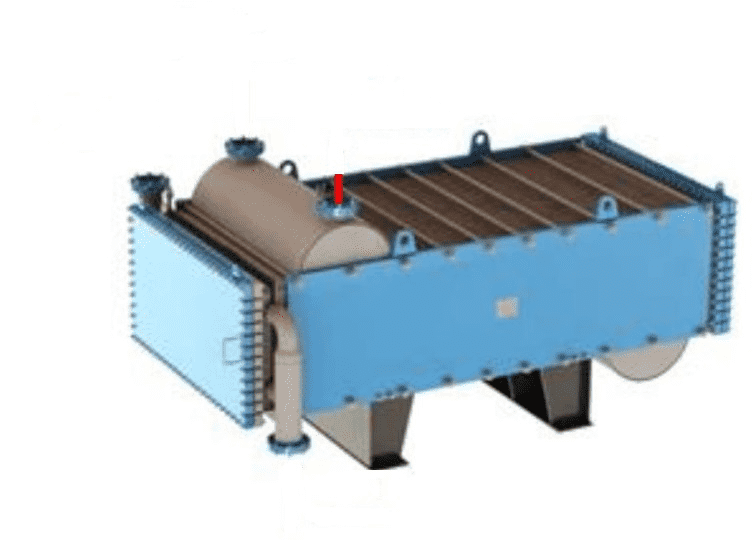

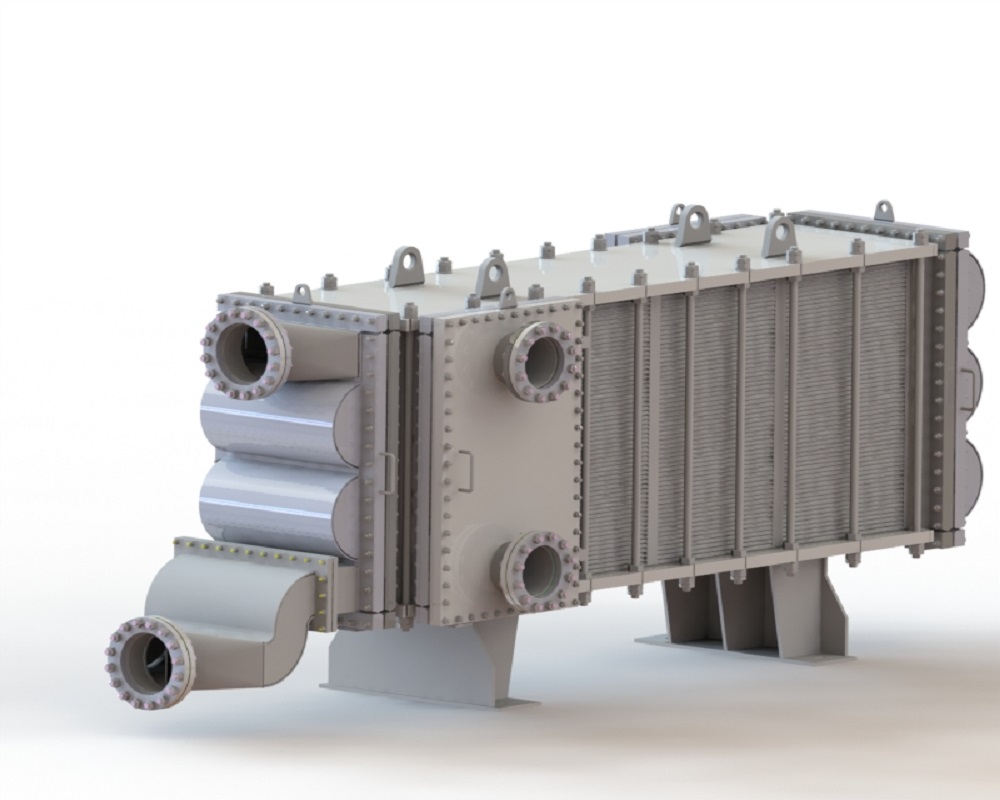

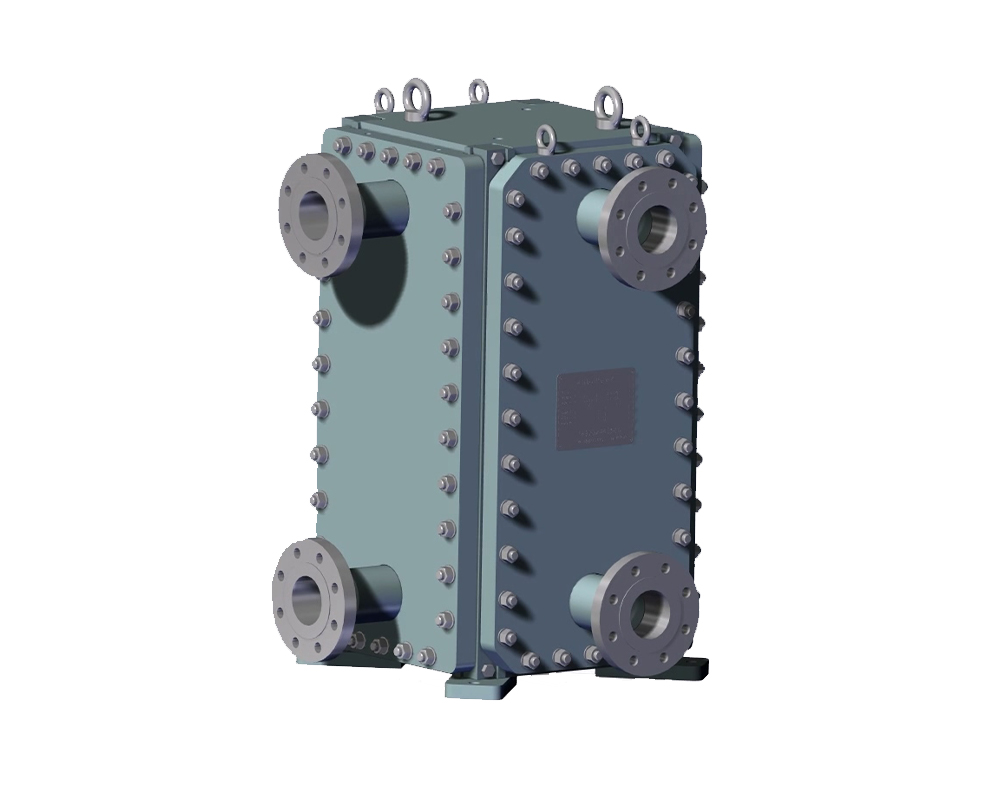

Wide Gap Welded Plate Heat Exchanger (WGPHE) Features

WGPHE from Shanghai Heat Transfer Equipment Co., are custom designed using finite element analysis. Moreover, the WGPHE is specifically constructed for heating or cooling of viscous or high solid containing process liquids. For example, process fluid which contain abrasive particles found in alumina or suspended long fibers found in food or ethanol mash.

An extreme application that demonstrates the impressive performance of the WGPHE is the Inter Stage Cooler of the alumina process. SHPHE has manufactured and delivered over 2000 WGPHEs and satisfactorily supplied them – both as OEM and replacement applications for many years for the alumina inter-stage cooler. A list of successful installations available upon request.

The WGPHE is designed to not only manage non Newtonian clogging liquids but also to resist abrasion caused by hydrate particle in slurry. Specifically, the WGPHE is formulated with fused metal coating applied to selected high wear areas of the heat exchanger. The result significantly increases life cycle coupled with reduction in cost of ownership.

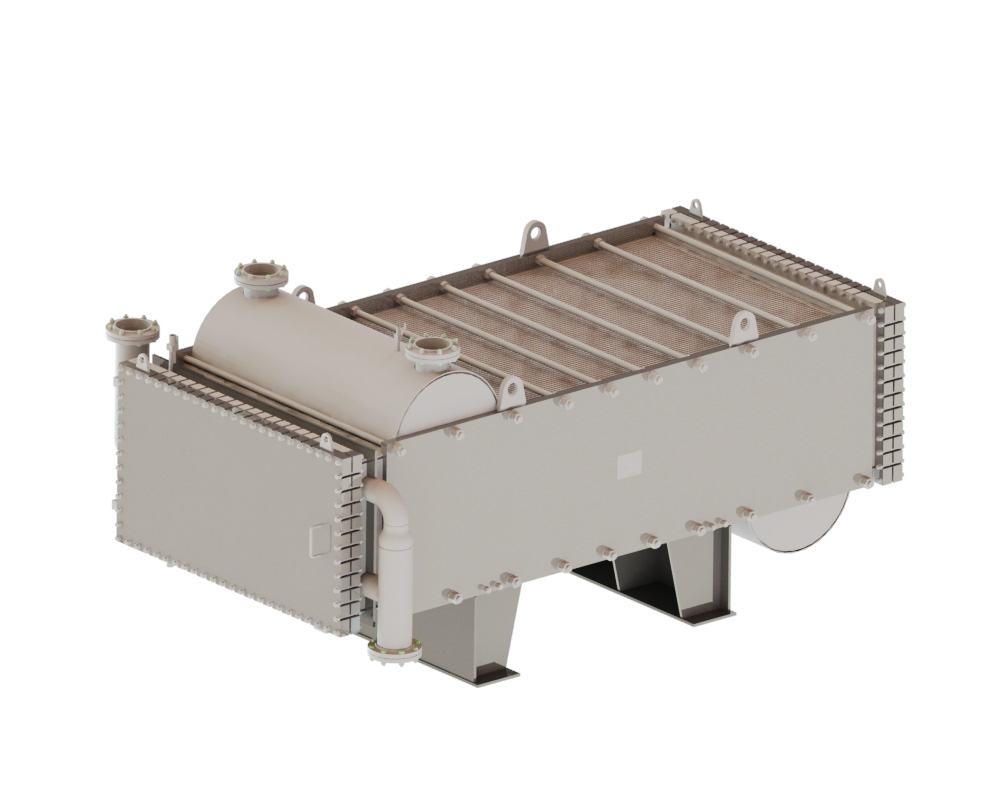

Visible straight line flow channel

The WGPHE is frequently specified in other industrial applications including; ethanol, food processing, pulp & paper, sugar production and chemical process industries. Moreover, Shanghai Heat Transfer Equipment designs the WGPHE to solve many unique thermal transfer challenges where either clogging or abrasion is a major issue. The WGPHE thermal efficiency is considerably higher than a shell & tube heat exchanger contributing further added economic value when considering this replacement.

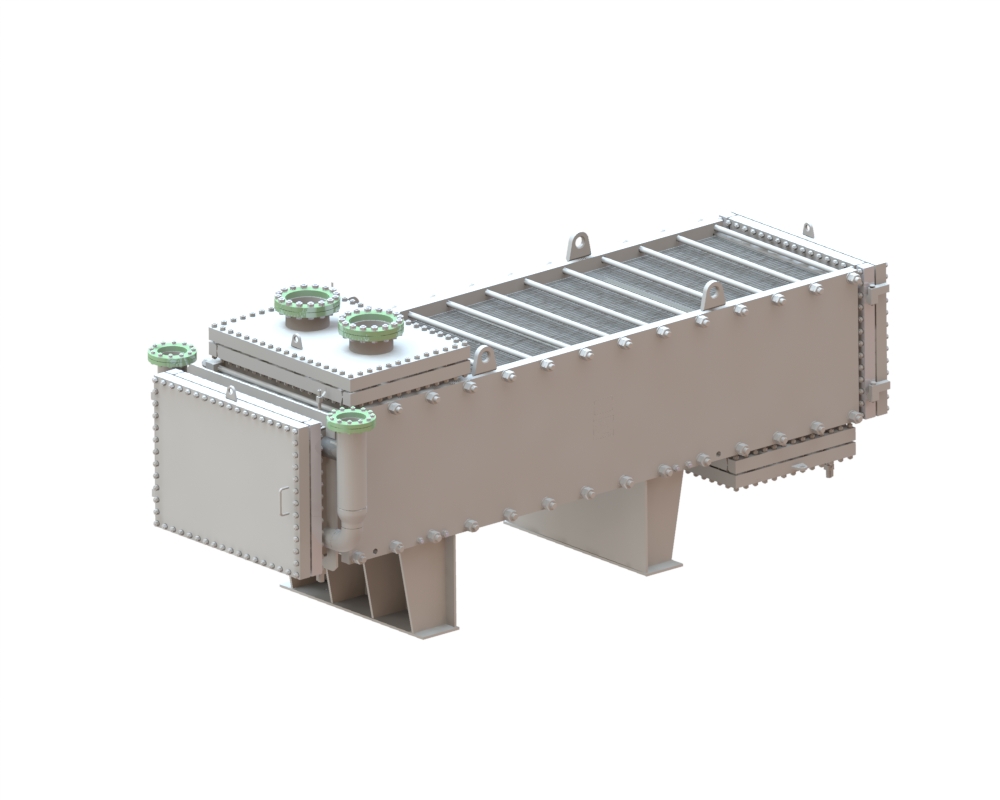

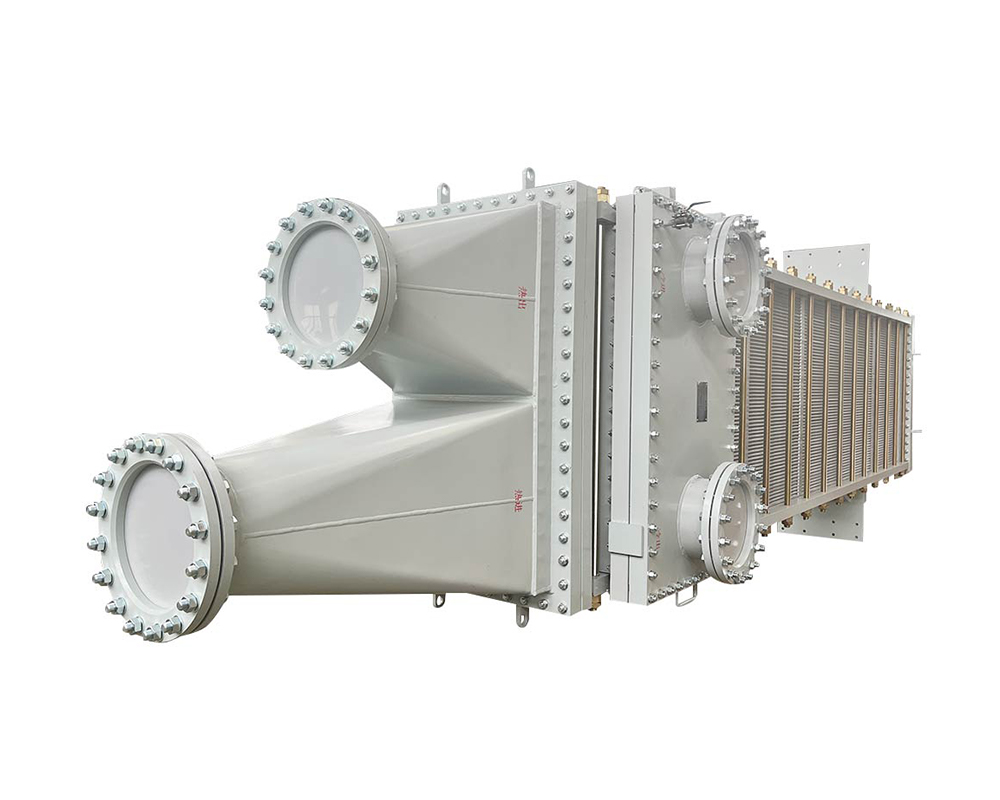

Shanghai Heat Transfer WGPHXs Successfully Commissioned and operational in Australia

SHPHE was awarded order in 2020 and 2021 by an Australian client for replacement of failed precipitation cooling heat exchanger manufactured by others in the plant. They are now successfully performing as requested and promised.

Precipitation cooling heat exchanger in Australia

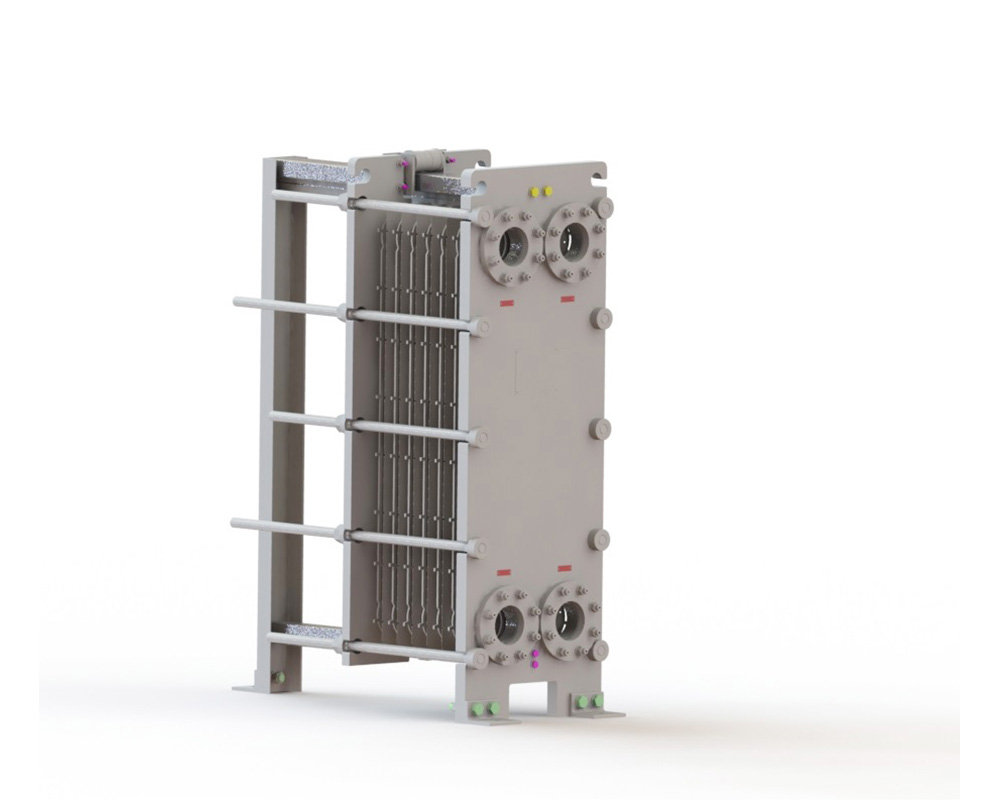

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for 2019 New Style Plate Heat Eanger For Waste Heat Recovery - Precipitation Cooling Heat Exchanger in Alumina Refinery – Shphe , The product will supply to all over the world, such as: Saudi Arabia , Latvia , Sevilla , Based on products with high quality, competitive price, and our full range service, we have accumulated professional strength and experience, and we have built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality products and passionate service. Let's open a new chapter of mutual benefit and double win.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!