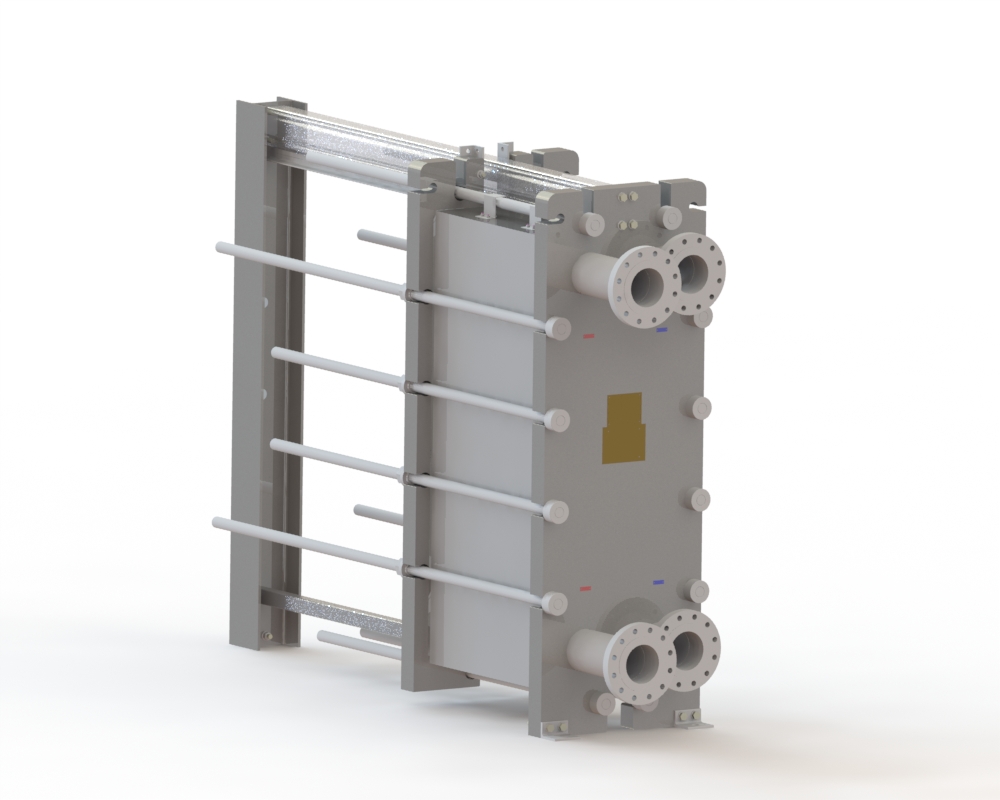

18 Years Factory Wide Gap Waster Water Cooling - TP Fully Welded Plate Heat Exchanger for high temperature and high pressure – Shphe

18 Years Factory Wide Gap Waster Water Cooling - TP Fully Welded Plate Heat Exchanger for high temperature and high pressure – Shphe Detail:

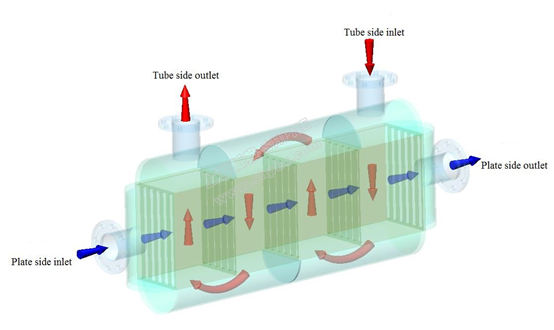

How it works

Features

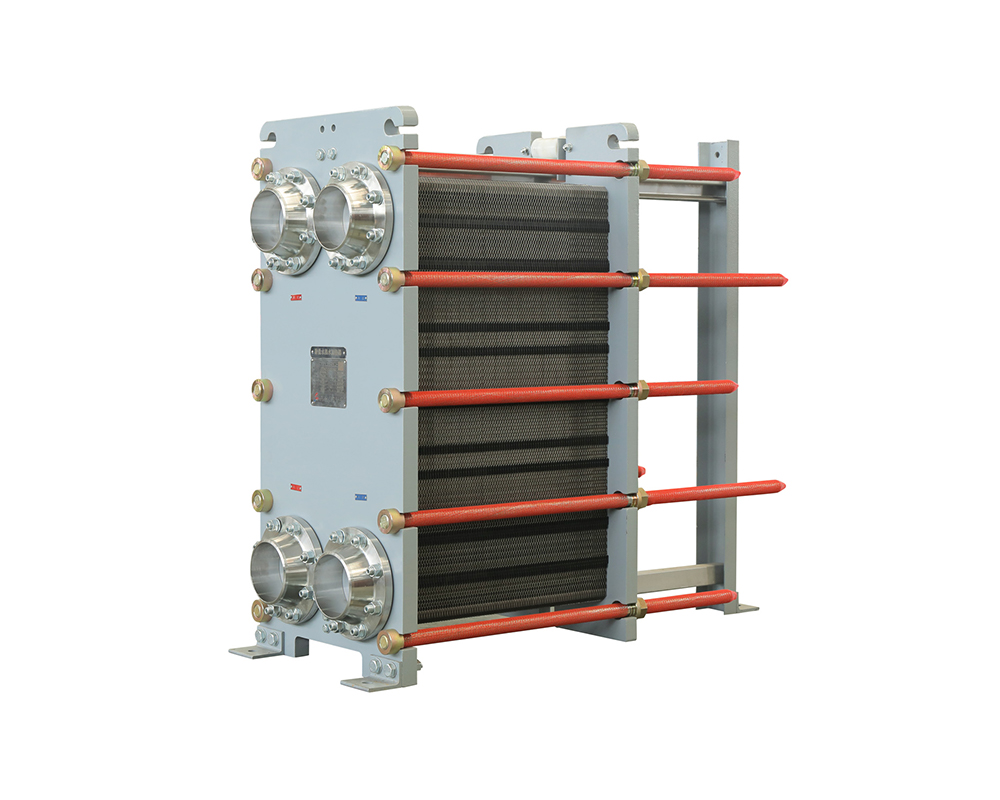

☆ The unique designed plate corrugation form plate channel and tube channel. Two plates stacked to form sine shaped corrugated plate channel, the plate pairs stacked to form elliptically tube channel.

☆ Turbulent Flow in plate channel results high heat transfer efficiency, while tube channel has the feature of small flow resistance and high press. resistant.

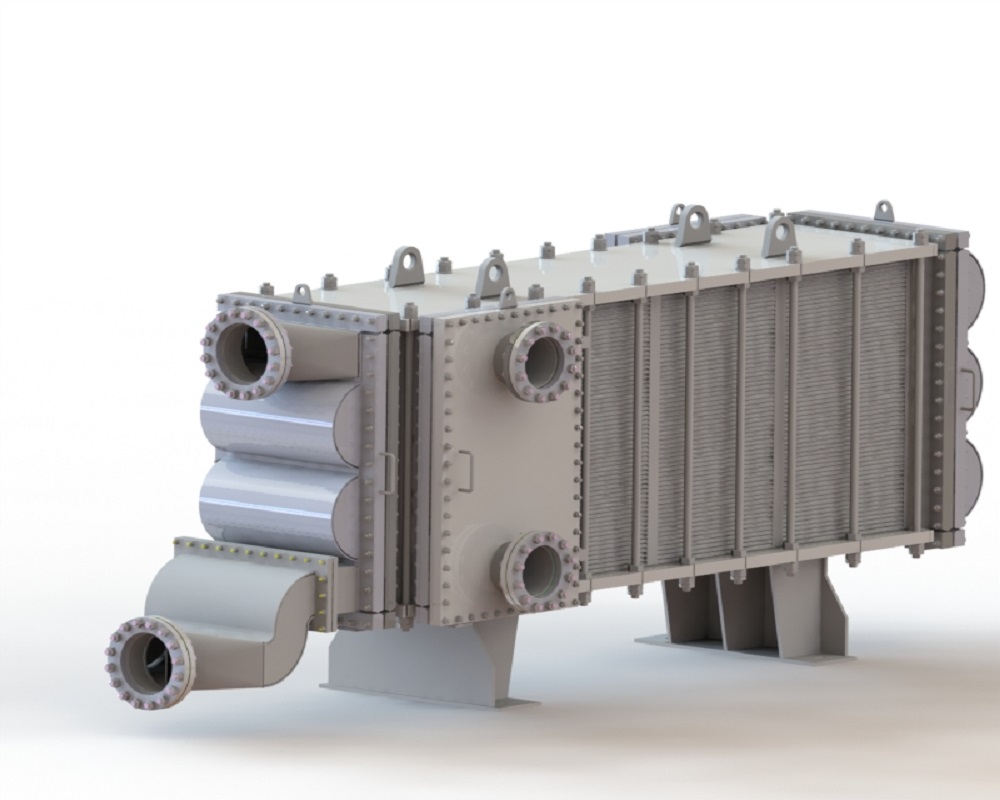

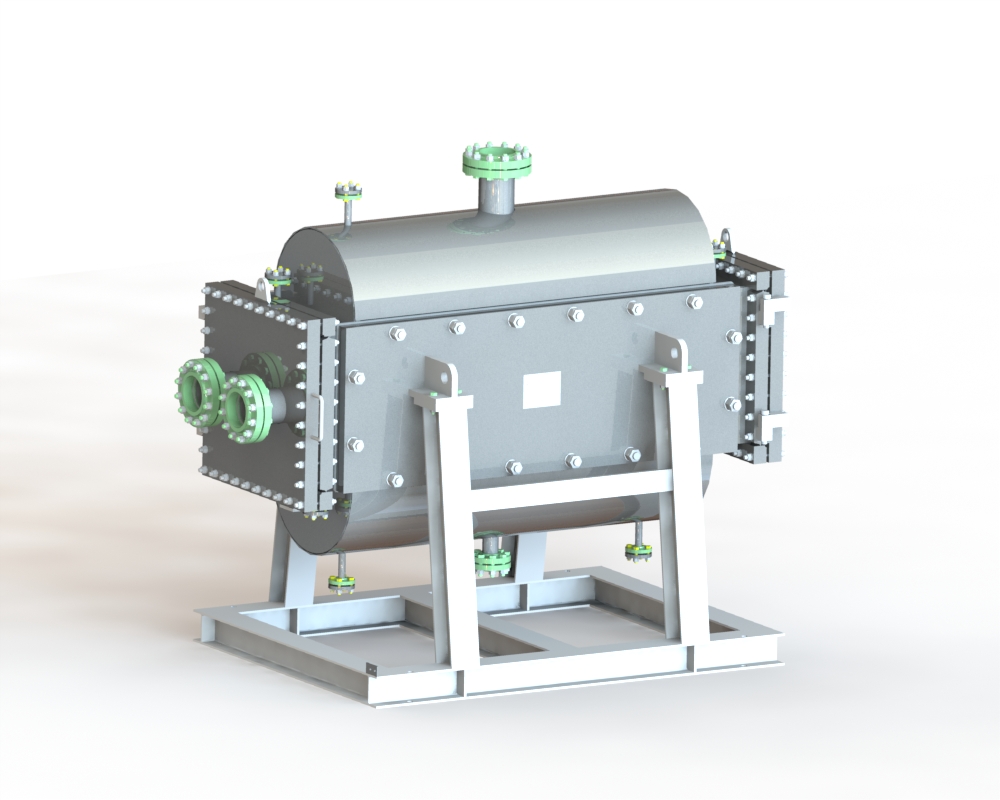

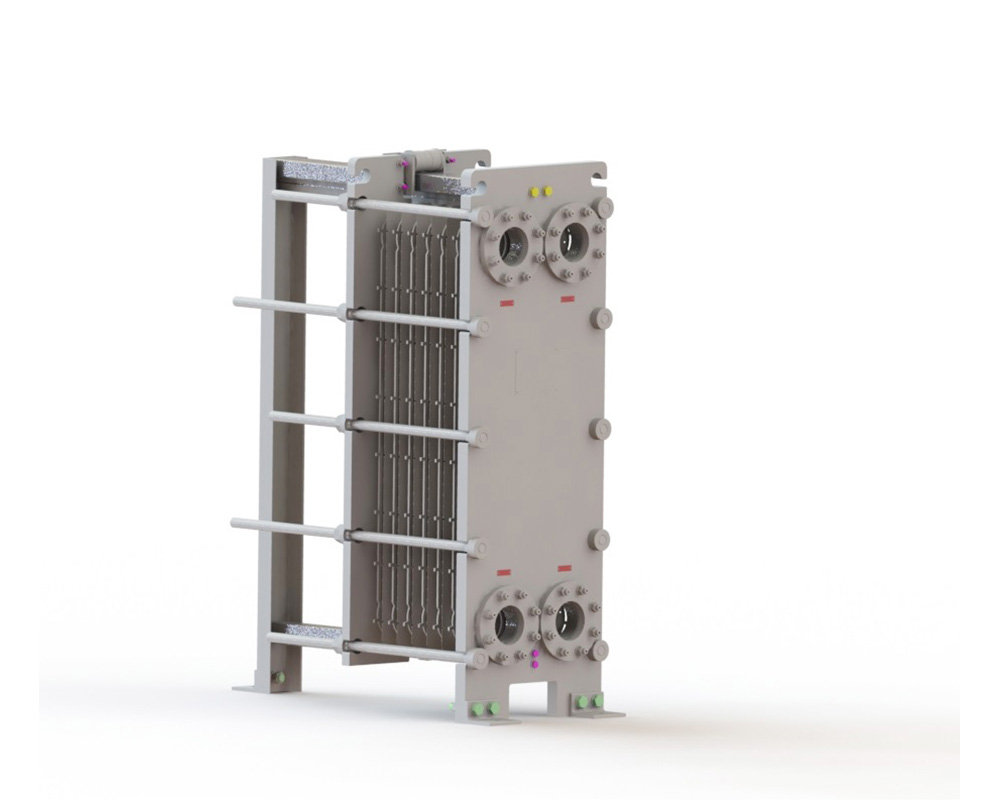

☆ Fully welded structure, safe and reliable, suitable for high temp., high press. and hazardous application.

☆ No dead area of flowing, removable structure of tube side facilitate mechanical cleaning.

☆ As condenser, super cooling temp. of steam can be well controlled.

☆ Flexible design, multiple structures, can meet requirement of various process and installation space.

☆ Compact structure with small footprint.

Flexible flow pass configuration

☆ Cross flow of plate side and tube side or cross flow and counter flow.

☆ Multiple plate pack for one heat exchanger.

☆ Multiple pass for both tube side and plate side. Baffle plate can be re-configured to suit changed process requirement.

Range of application

Variable structure

Condenser: for vapor or condensing of organic gas, can meet condensate depression requirement

gas-liquid: for temp. drop or dehumidifier of wet air or flue gas

Liquid-liquid: for high temp., high press.Flammable and explosive process

Evaporator, condenser: one pass for phase change side, high heat transfer efficiency.

Application

☆ Oil refinery

● Crude oil heater, condenser

☆ Oil & gas

● Desulfurization, decarburization of natural gas – lean/rich amine heat exchanger

● Dehydration of natural gas – lean / rich amine exchanger

☆ Chemical

● Process cooling / condensing / evaporation

● Cooling or heating of various chemical substances

● MVR system evaporator, condenser, pre-heater

☆ Power

● Steam condenser

● Lub. Oil cooler

● Thermal oil heat exchanger

● Flue gas condensing cooler

● Evaporator, condenser, heat regenerator of Kalina cycle, Organic Rankine Cycle

☆ HVAC

● Basic heat station

● Press. isolation station

● Flue gas condenser for fuel boiler

● Air dehumidifier

● Condenser, evaporator for refrigeration unit

☆ Other industry

● Fine chemical, coking, fertilizer, chemical fiber, paper & pulp, fermentation, metallurgy, steel, etc.

Product detail pictures:

Related Product Guide:

Cooperation

Plate Heat Exchanger made with DUPLATE™ plate

With advanced technologies and facilities, strict high-quality handle, reasonable rate, superior services and close co-operation with prospects, we are devoted to furnishing the best price for our customers for 18 Years Factory Wide Gap Waster Water Cooling - TP Fully Welded Plate Heat Exchanger for high temperature and high pressure – Shphe , The product will supply to all over the world, such as: Kuala Lumpur , Houston , Slovenia , We've been persisting in the business essence "Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying products and service. " Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.